Oil cylinder

A technology of an oil cylinder and an outer cylinder block is applied in the field of speed-regulating equipment for impact-type hydro-generators, which can solve the problems of waste of water resources, cumbersome operation, large hydraulic loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

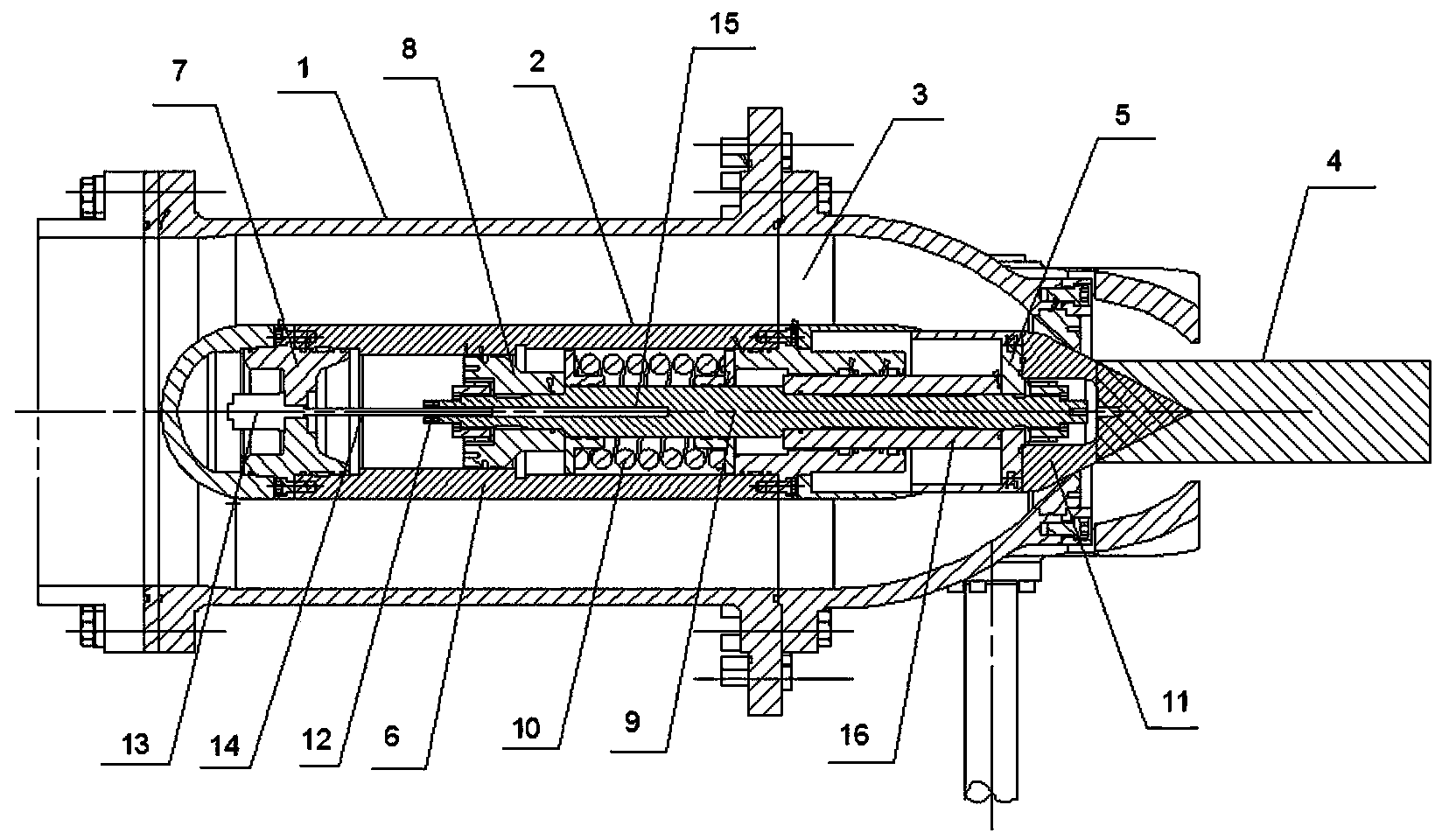

[0012] like figure 1 As shown, an oil cylinder includes an outer cylinder body 1 and an inner cylinder body 2 connected by at least one positioning joint 3, and the inner cylinder body 2 includes a cylinder barrel 6, a front cover 5 and a rear cover 7, and the The side of the outer cylinder body 1 corresponding to the front cover 5 is provided with a tapered opening, the outer side of the opening is fixedly connected with the nozzle 4, and the outside of the front cover 5 is fixedly connected with a coaxial conical head 11. The conical head 11 can pass through the opening of the outer cylinder body 1 and can block the nozzle pipe 4; the inner cylinder body 2 is provided with a coaxial piston 8 and a piston rod 9, and a sleeve on the outside of the piston rod 9 Spring 10, the two ends of this spring 10 are all provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com