Fuel cutting method for multi-fuel blending combustion unit under run back (RB) condition

A fuel co-combustion and unit technology, which is applied in the direction of using multiple fuel combustion, combustion methods, block fuel and liquid fuel combustion, etc., can solve the problems of water supply control requirements and high response, large water supply buffer volume, etc., to achieve Satisfy boiler heat load demand, good load fluctuation, good effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

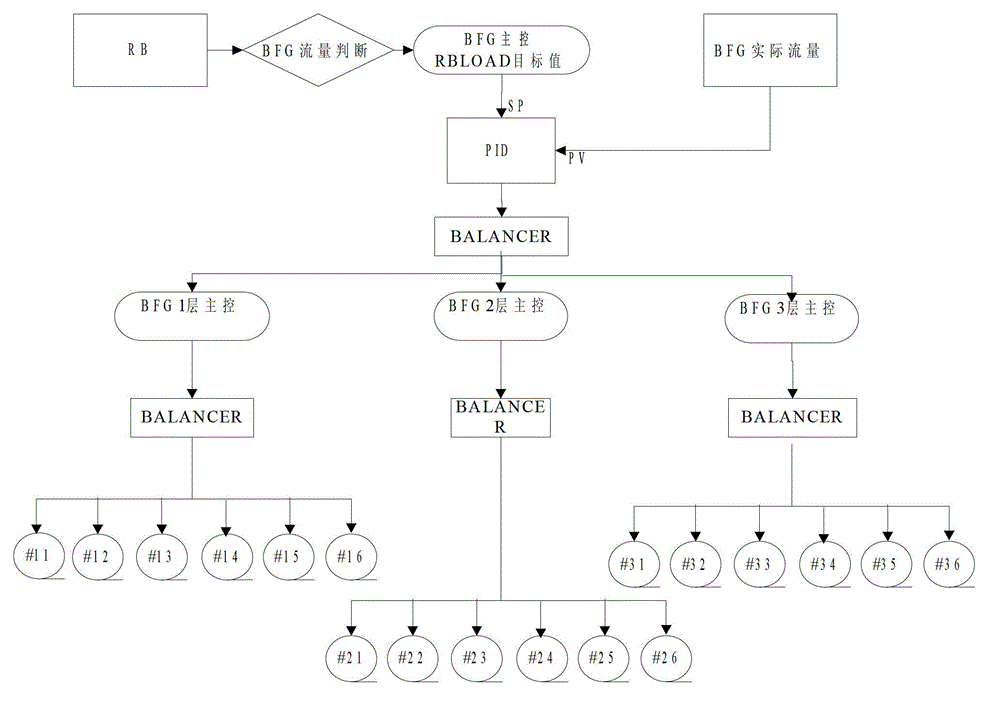

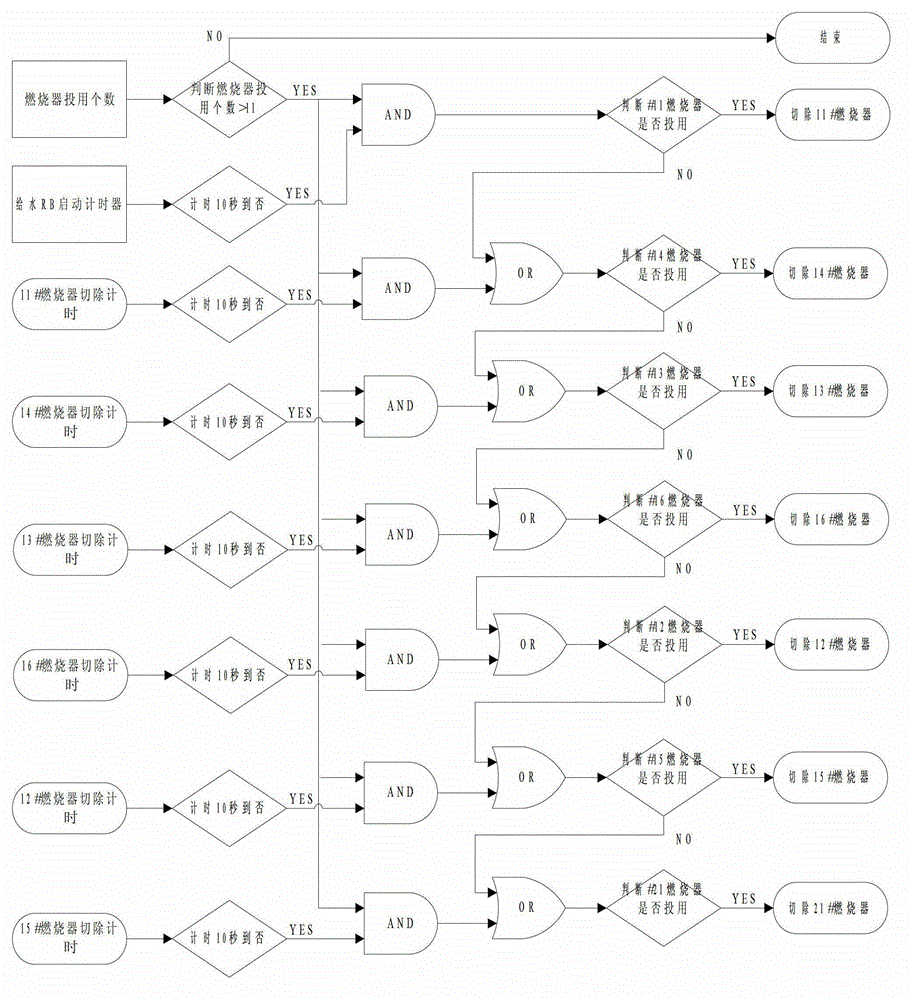

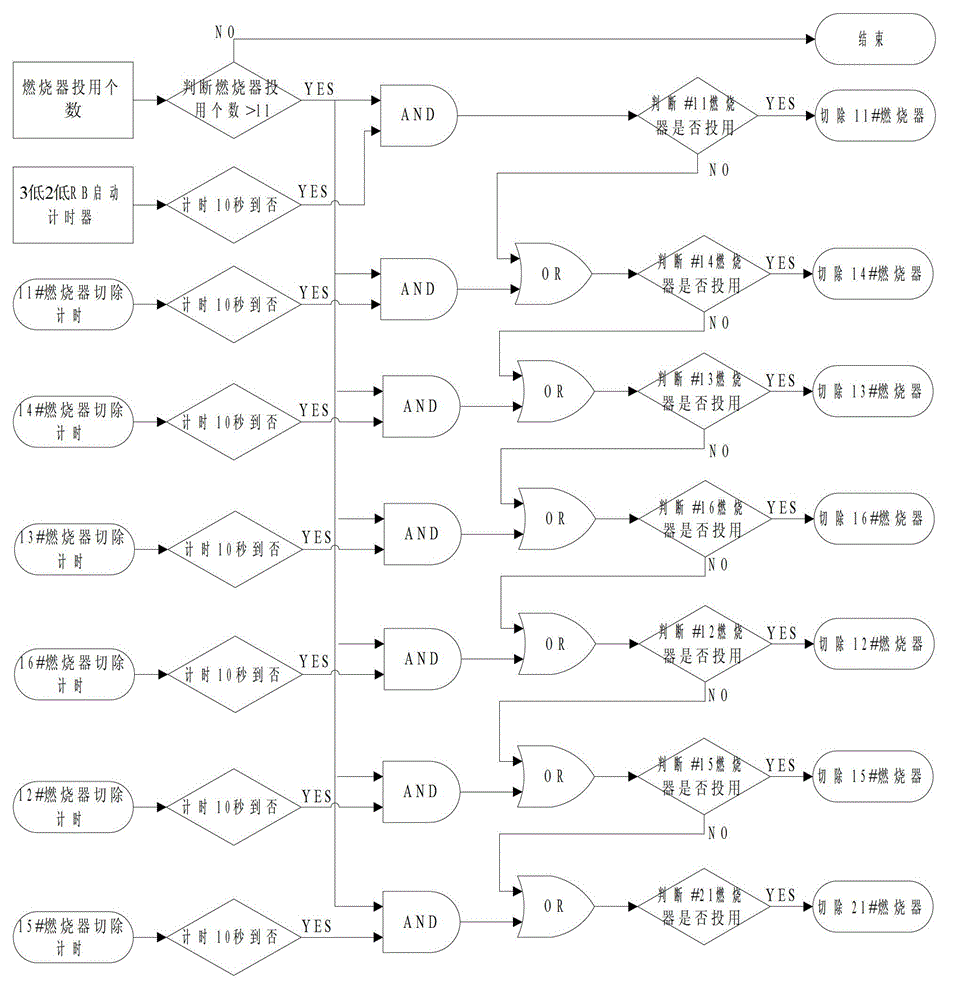

[0045] The present invention uses the DCS system (distributed control system) to analyze and identify the fault tripping of important auxiliary equipment (RUNBACK working condition, referred to as RB working condition), and then adopts a safe process strategy and programming to realize fully automatic stable unit operation; its The key technology is based on the mixed combustion of various fuels in Unit 4 of Baosteel Power Plant; 18 composite gas burners, divided into upper, middle and lower layers, and the characteristics of the left and right walls facing each other, it gives how to correctly identify and diagnose each gas burner. According to different RB working conditions, different boiler fuel cutting schemes are adopted according to diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com