A water-cooled heat flow sensor

A heat flow sensor, water-cooled technology, used in calorimeters, instruments, thermometers with directly sensitive electrical/magnetic components, etc., can solve the problems of affecting accuracy and insufficient heat flow sensor accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

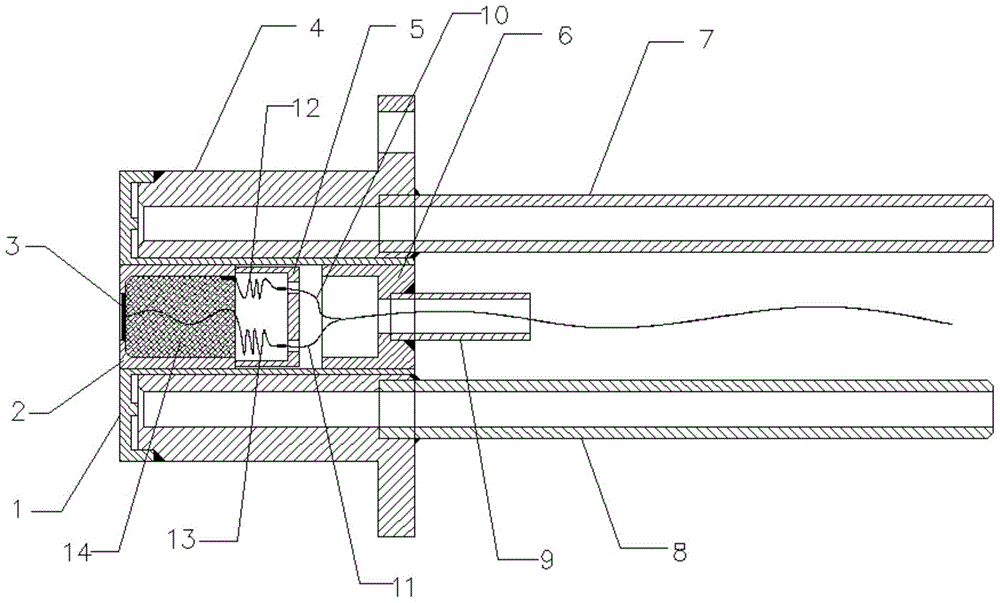

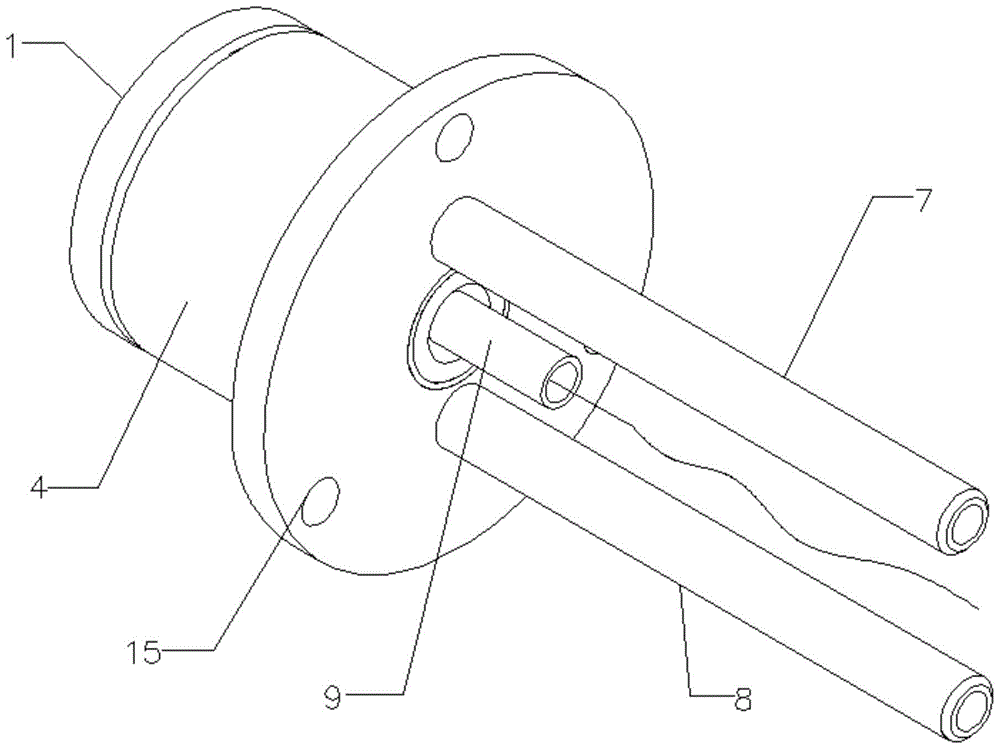

[0019] Such as figure 1 and figure 2 As shown, a water-cooled heat flow sensor includes: a front cover 1, the front cover 1 is on a rear cover 4; a rear cover 4, the rear cover 4 has an inner chamber and an outer chamber, and the inner chamber is close to the front cover A front inner core 2 is installed at the bottom of one end; the outer chamber is welded with a water inlet pipe 7 and an outlet pipe 8; A constantan plate 3 is installed inside; the inner space of the front inner core 2 is filled with heat-insulating paint 14; the top opening end surface of the front inner core 2 is installed with a heat-insulating sleeve 5; the rear inner core 6 is welded to the inner cavity of the rear cover 4 The end of the chamber away from the front end cover has a threading hole on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com