Steel jacket matching structure of gas pressure sensor

A technology of air pressure sensor and matching structure, applied in the field of sensors, can solve the problems of mutual separation, poor resistance to external force, low binding force, etc., to prevent displacement, ensure stability, and increase binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and embodiments.

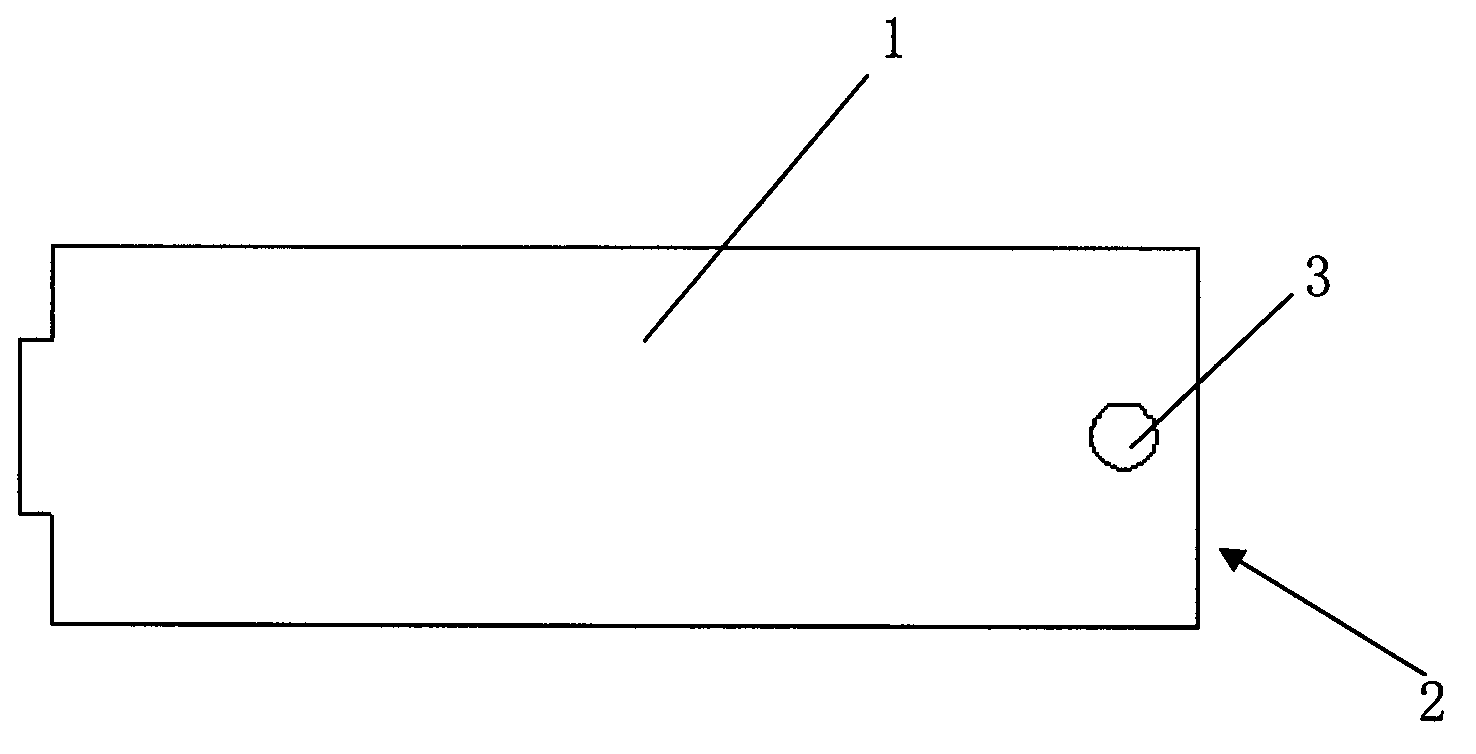

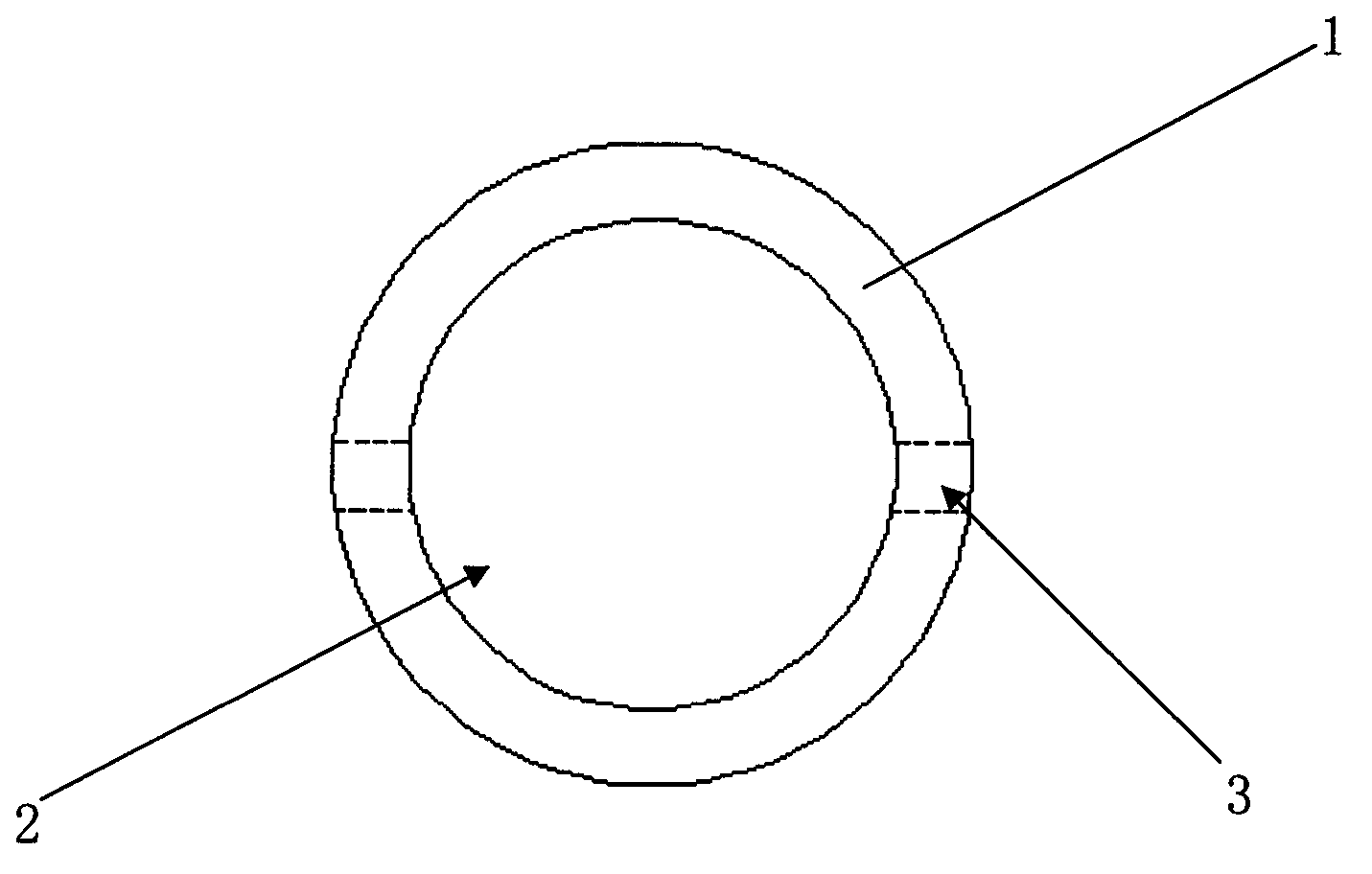

[0015] figure 1 It is a front view of the steel sleeve of the steel sleeve matching structure of the air pressure sensor of the present invention; figure 2 It is a schematic diagram of the position of the injection port of the steel sleeve in the steel sleeve matching structure of the air pressure sensor of the present invention.

[0016] Such as figure 1 , figure 2 As shown, the steel sleeve matching structure of the air pressure sensor of the present invention includes: a steel sleeve, which constitutes the outer structure of the air pressure sensor. The steel sleeve is hollow and forms a space inside. One end of the steel sleeve is provided with an injection port corresponding to the steel sleeve. A plurality of through holes are arranged at the edge of the cylinder wall on one side of the injection port.

[0017] There are two through holes arranged at the edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com