Imaging equipment for laser printed product quality detection system and corresponding detection system

A technology of imaging equipment and detection system, which is applied in the direction of scattering characteristic measurement, etc., can solve the problems of weakening the acquisition ability of the camera's concave-convex information, production quality problems and the inability to carry out effective detection, and achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

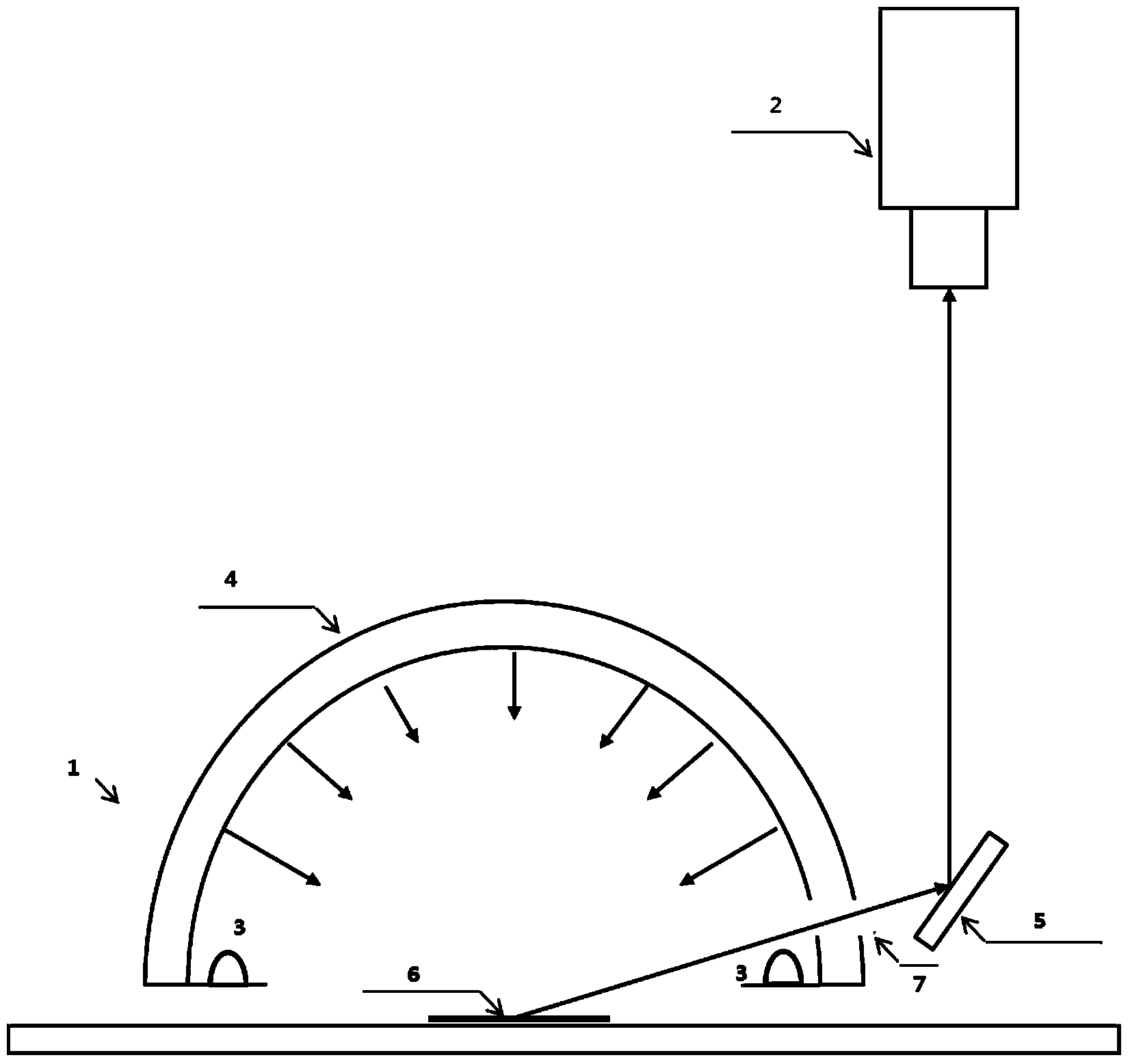

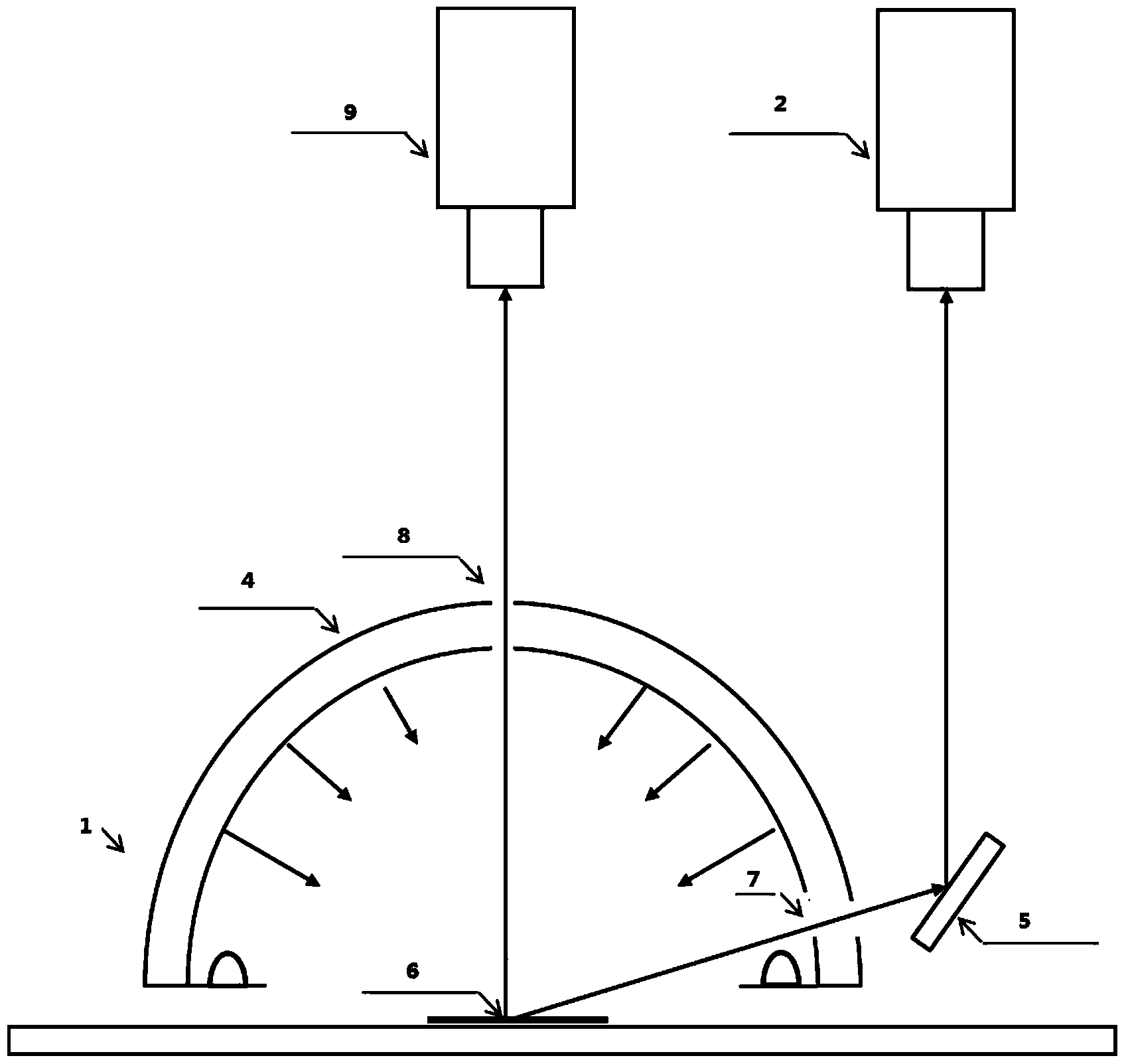

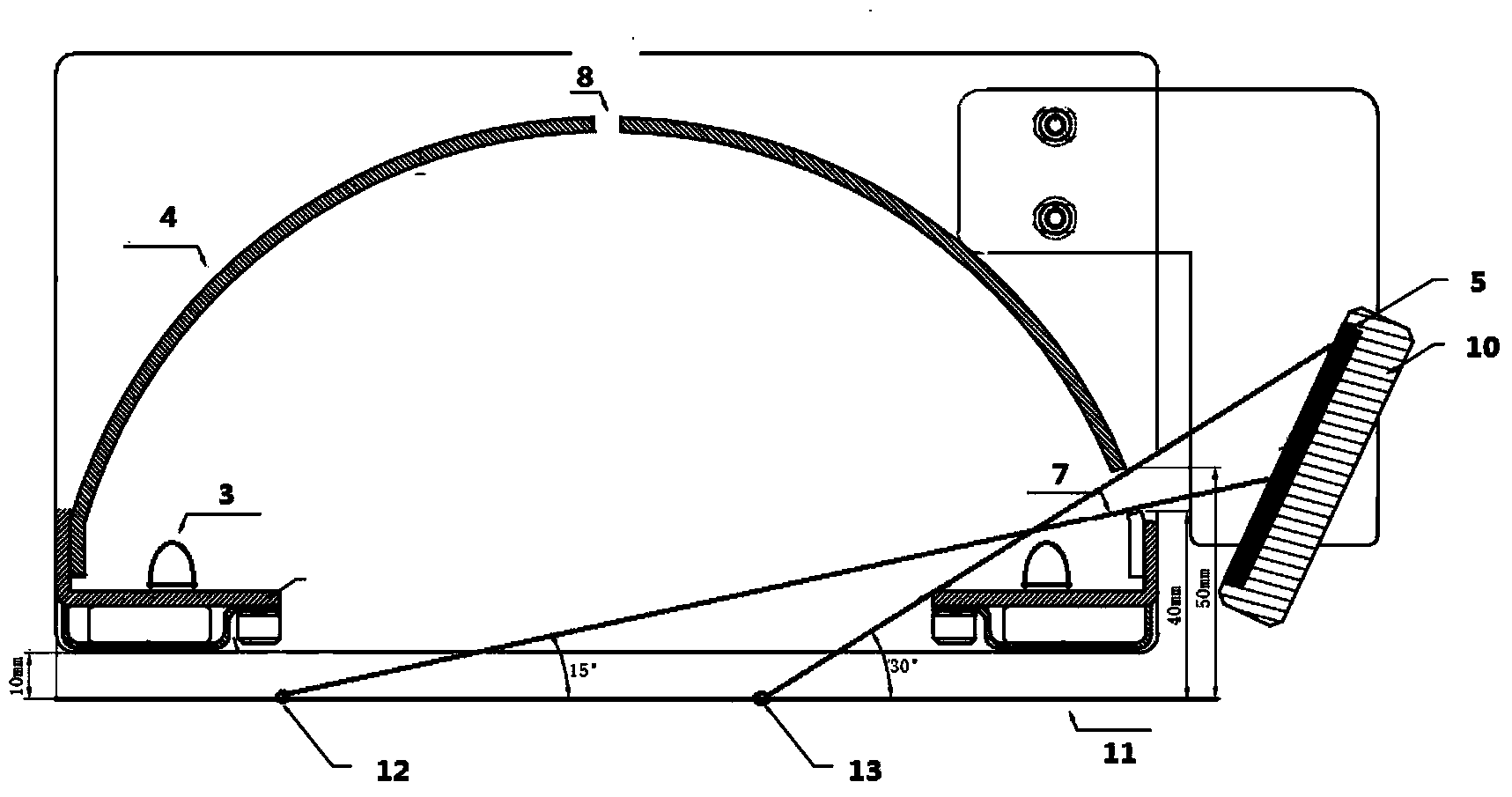

[0027] figure 1 An imaging device according to one embodiment of the present invention is shown. Such as figure 1 As shown, the imaging device includes a diffuse illumination light source 1 and an image acquisition device 2 . In this embodiment, the diffuse illumination light source 1 includes several LED light sources 3 and diffuse reflection arcs 4 . Optionally, the imaging device further includes a reflector 5 for turning back the collection light path of the image collection device, so that the imaging device of the present invention is more compact.

[0028] In this embodiment, the diffuse reflection arc 4 is semi-cylindrical, and the inner surface of the semi-cylindrical diffuse reflection arc 4 is coated with a material with high diffuse reflectance. For example, the inner surface of the diffuse reflection arc 4 is sprayed with a material mixed with barium sulfate, latex and water. Those skilled in the art should understand that although the LED light source and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com