A three-core separately excited three-phase magnetron reactor

A magnetron reactor and iron core column technology, which is applied in the field of three-iron core column separately excited three-phase magnetron reactor, can solve the problems of limiting the promotion and application of the magnetron reactor, high harmonic content of working current, and low material utilization. , to achieve the effect of material saving, low magnetic field harmonic content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

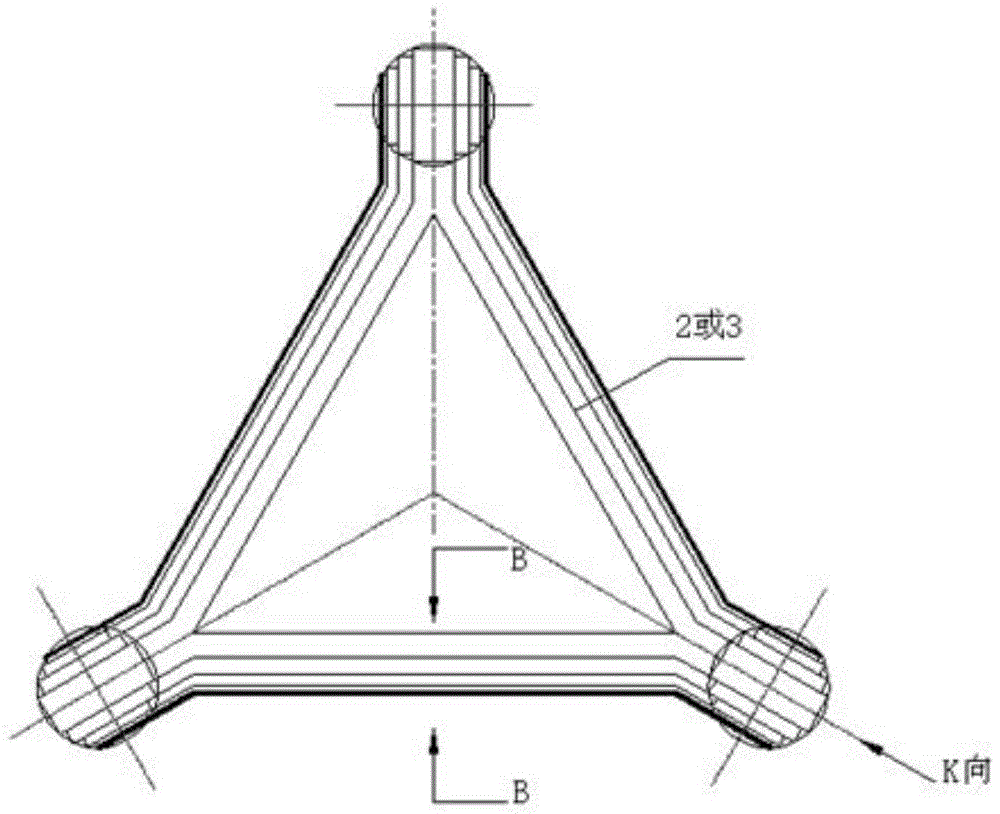

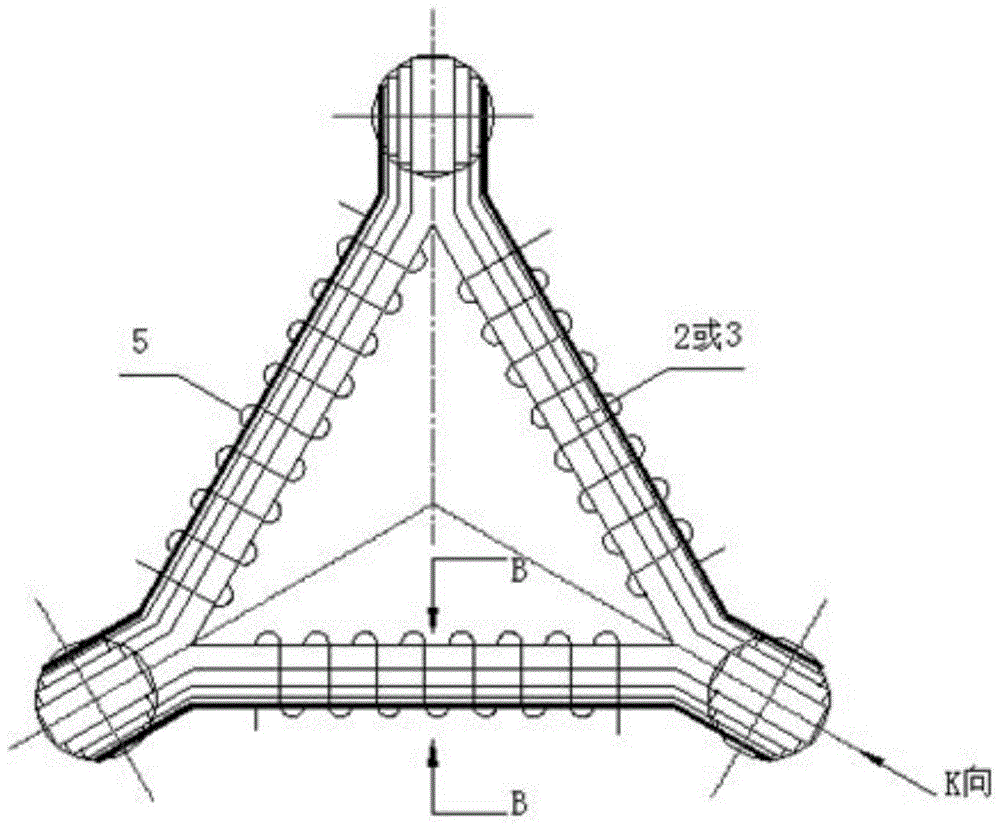

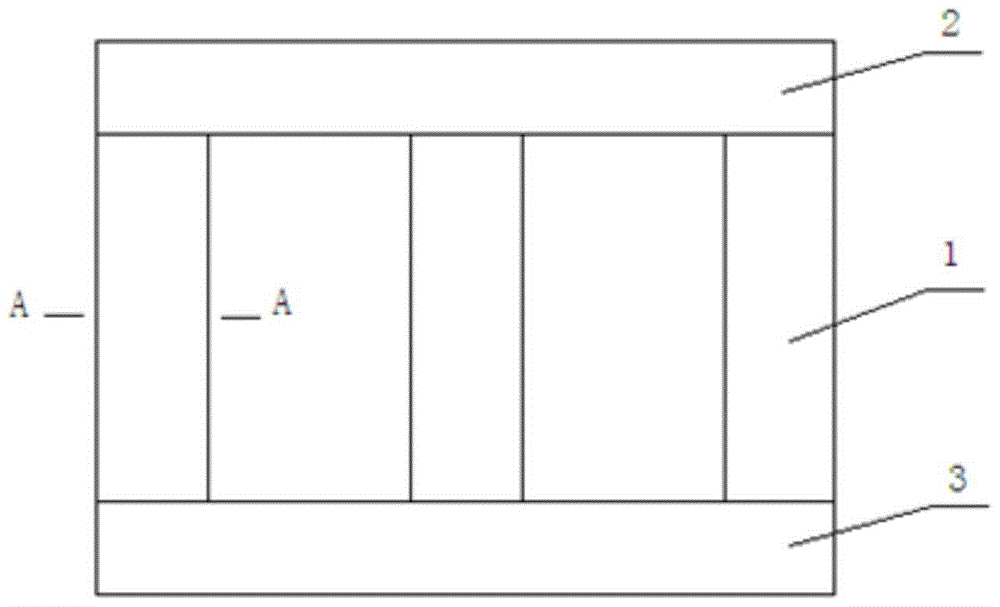

[0024] Such as Figure 1-5 As shown, a three-core separately excited three-phase magnetron reactor includes three main core columns 1, an upper yoke 2, a lower yoke 3, three working windings 4, an upper yoke control winding 5 and a lower yoke control winding 5 , the three main core columns 1 are provided with three working windings 4, the upper yoke 2 and the lower yoke 3 are respectively provided with an upper yoke control winding 5 and a lower yoke control winding 5, and the upper yoke 2 and the lower yoke 3 are plugged in respectively On the two ends of the three main core columns 1, the two ends of the core pieces of the upper yoke 2 and the lower yoke 3 are folded into obtuse angles to form a structure with a straight line at the end and a triangle in the middle. By controlling the upper and lower yokes, the winding 5 The DC current can change the saturation degree of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com