An adjustable air gap ironless linear motor

A linear motor and adjustable technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of damaged motor components, reduced motor service life, increased motor back electromotive force, etc., to improve service life and reduce Back EMF, the effect of reducing harmonic back EMF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

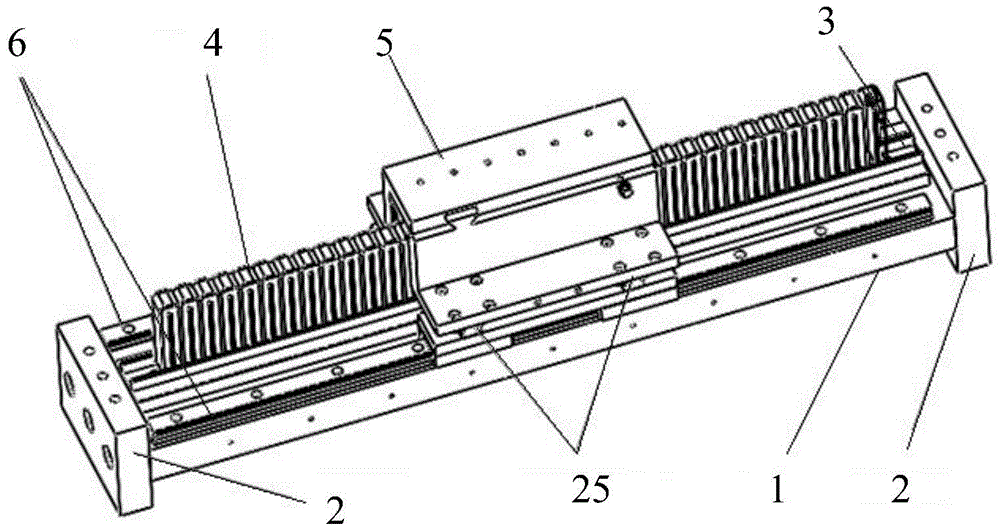

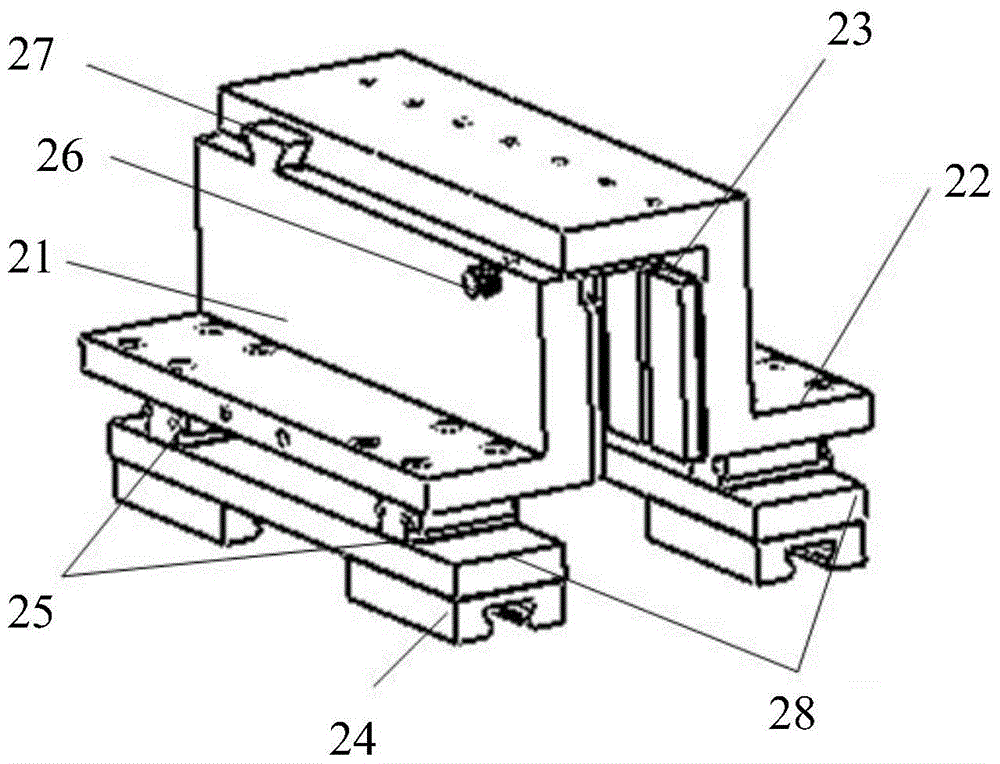

[0025] In traditional technology, in order to improve the driving force of the ironless motor, the linear motor is generally designed as a double-sided structure, which increases the back electromotive force of the motor and requires higher DC bus voltage, and the back electromotive force is more harmful. The electromotive force is large, and if it is not handled properly, it is likely to damage the components of the motor, resulting in a reduction in the service life of the motor and increasing the cost of use. Therefore, it is particularly critical to keep the back electromotive force of the ironless linear motor low when the motor is running at high speed.

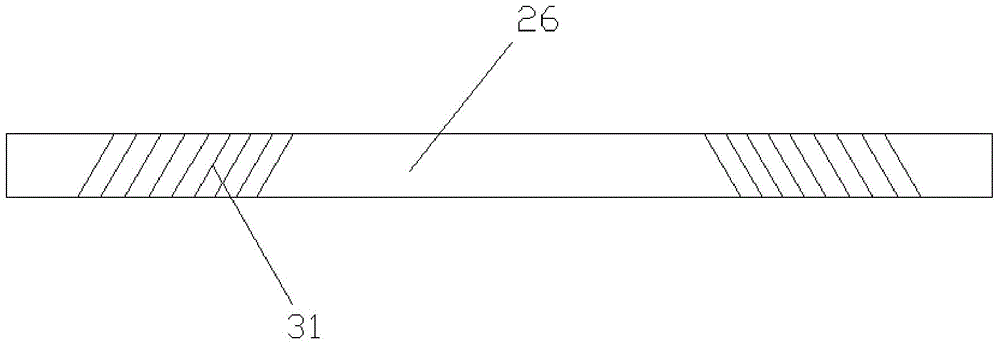

[0026] Aiming at the deficiencies in the prior art, the present invention provides a coreless linear motor with an adjustable air gap. When the linear motor needs a large motor driving force, the air gap of the motor can be changed by adjusting the air gap of the motor. If the air gap is small, the magnetic density of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com