High-power rotating rectifier module

A rotary rectification, high-power technology, applied in the field of high-power rotary rectification components, can solve the problems of high failure rate, short service life, low reliability, etc., and achieve low failure rate, convenient installation and use, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

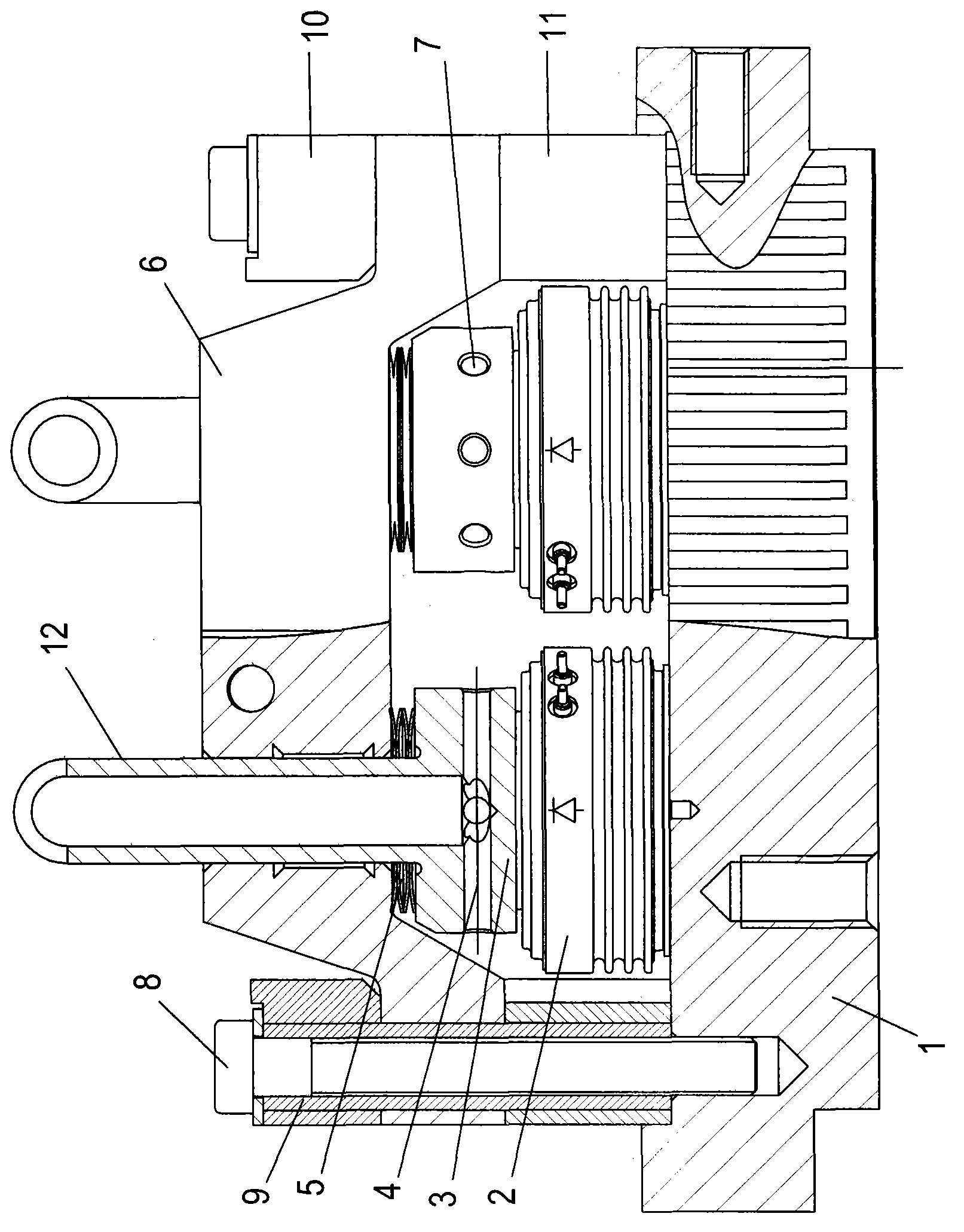

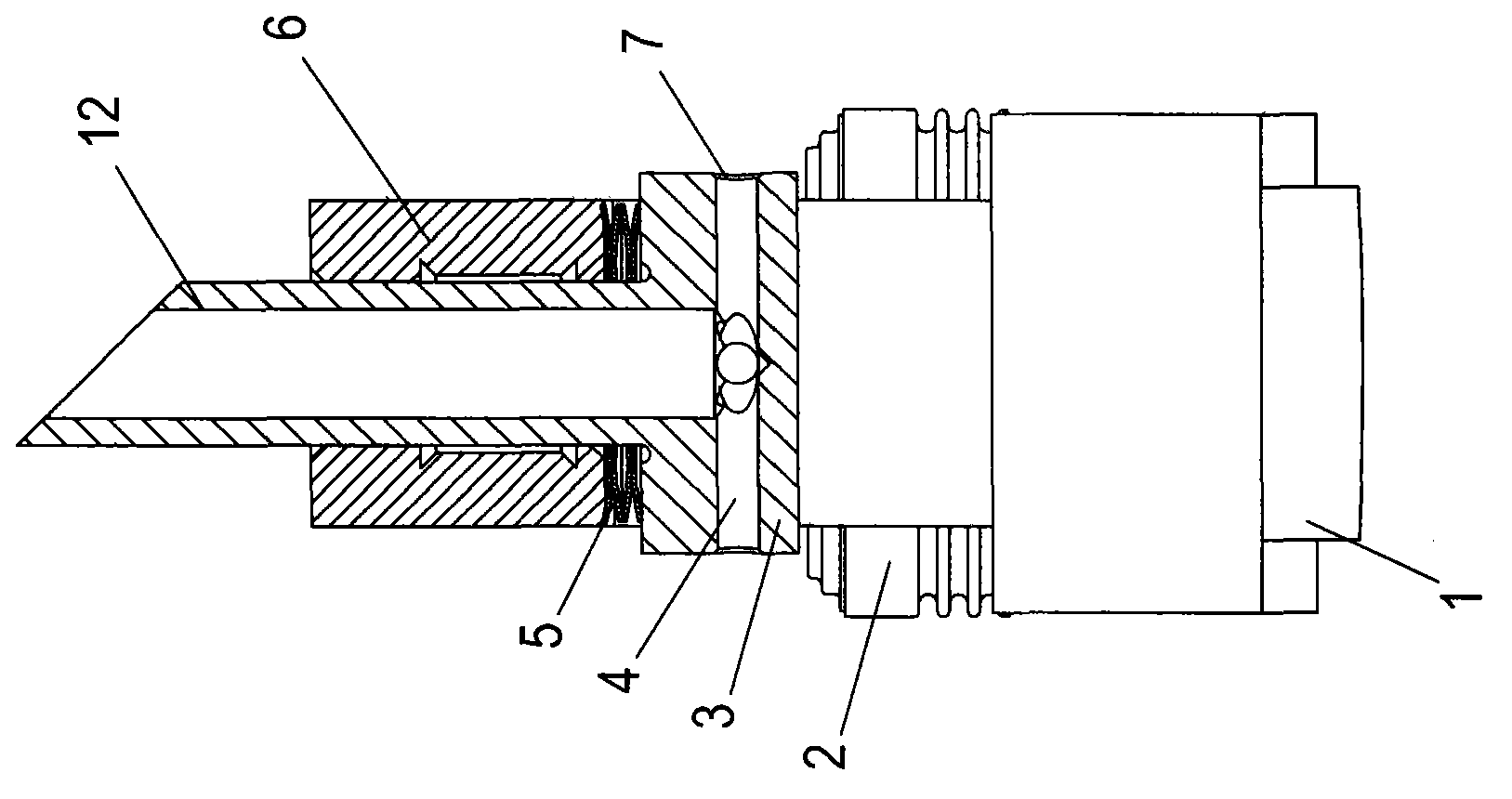

[0012] like figure 1 and figure 2 As shown, the high-power rotary rectifier assembly of the present invention includes a heat sink 1 made of metal, the top of the heat sink 1 is attached to the lower end faces of two rectifier diodes 2, and the lower end faces of the rectifier diodes 2 are positive or negative. The upper end surfaces of each rectifier diode 2 are attached to the lower end surfaces of a heat dissipation pressing block 3 respectively, and each heat dissipation pressing block 3 is respectively provided with a heat dissipation channel 4, and the heat dissipation channel 4 has an air inlet and a plurality of air outlets 7, and the heat dissipation channel 4 The air inlet is located at the top of the heat dissipation compact 3, and the plurality of air outlets 7 of the heat dissipation channel 4 are evenly distributed on the side wall of the heat dissipation compact 3, and the air inlets on the upper end surface of each heat dissipation compact 3 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com