DC motor speed differential feedback control device and method

A technology of DC motors and control methods, applied in the direction of DC motor speed/torque control, control systems, electrical components, etc., can solve the problems of overdrive easily caused by equivalent damping, achieve dynamic response time without overshoot and oscillation, and respond Increased speed and avoid blindness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

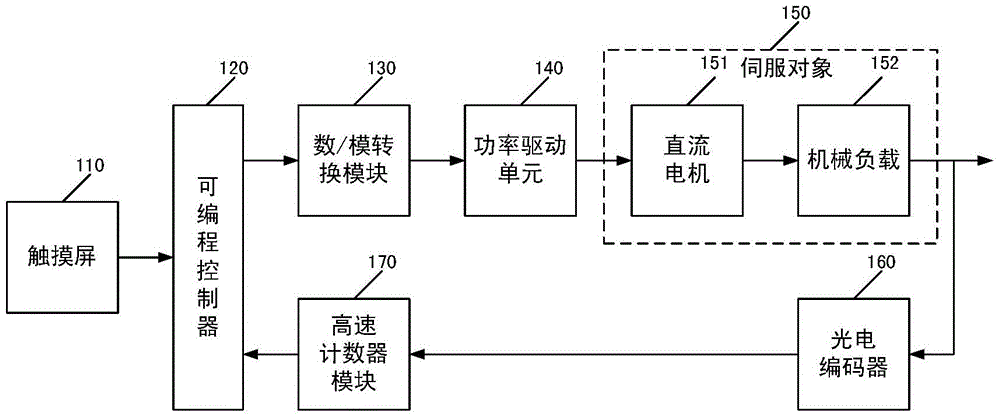

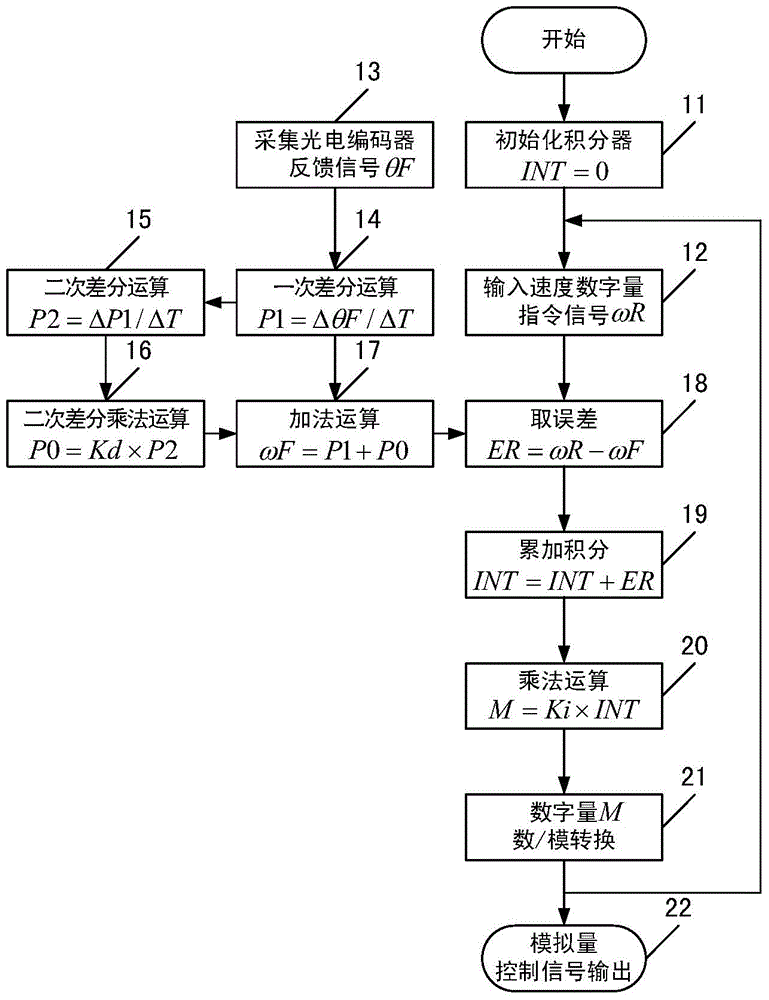

[0032] Such as figure 1 Shown is a block diagram of the DC motor speed differential feedback control device and method according to the embodiment of the present invention. The control device is composed of touch screen 110, programmable controller 120, digital / analog conversion module 130, power drive unit 140, servo object 150, photoelectric encoder 160 and high-speed counting module 170; programmable controller 120, digital / analog conversion Module 130, power drive unit 140, servo object 150, photoelectric encoder 160 and high-speed counting module 170 are connected circularly in a clockwise direction; wherein said programmable controller 120 is also connected with touch screen 110; 151 and the mechanical load 152 are connected in series in sequence, the DC motor 151 is also connected to the power drive unit 140 , and the mechanical load 152 is also connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com