A method for production control of complexed iron desulfurization process

A desulfurization process, a technology for complexing iron, applied in separation methods, chemical instruments and methods, petroleum industry, etc., can solve problems such as poor ratio selection, changing desulfurizers, etc., to reduce electricity consumption, avoid waste, and increase Effect of desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

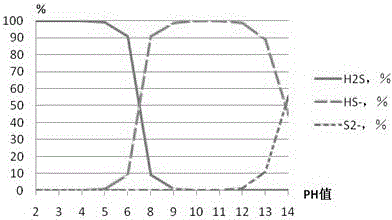

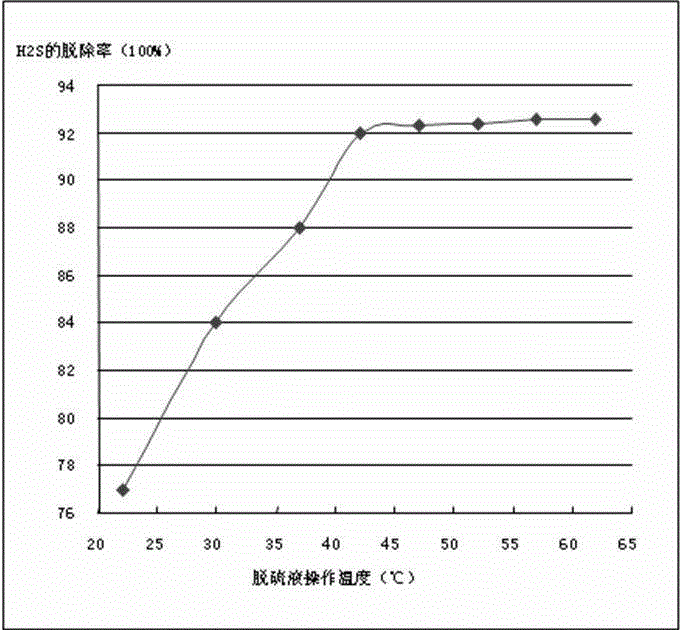

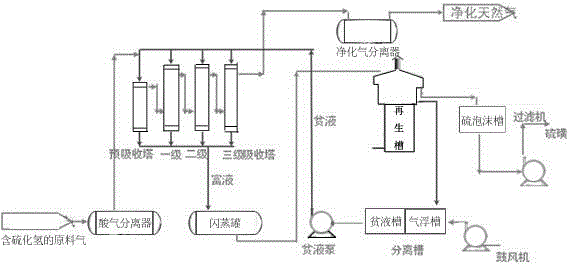

[0055] A method for production control of complexed iron desulfurization process. The raw material gas containing hydrogen sulfide passes through the acid gas separator to remove solid phase and liquid phase impurities, and then enters the absorption tower such as the pre-absorption tower in sequence, and is complexed with iron-poor The hydrogen sulfide gas is released by the liquid reaction, and the purified natural gas enters the purified gas separator to remove moisture, and is directly exported after passing the metering test;

[0056]In the absorption tower, the complexed iron-rich liquid that has absorbed sulfur enters the regeneration tower through the rich liquid flash tank and contacts with oxygen in the air to form a lean liquid that can absorb hydrogen sulfide again. The lean liquid enters the separation tank and passes through the lean liquid The pump enters the absorption tower again to complete the circulation of the whole desulfurization liquid. The rich liquid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com