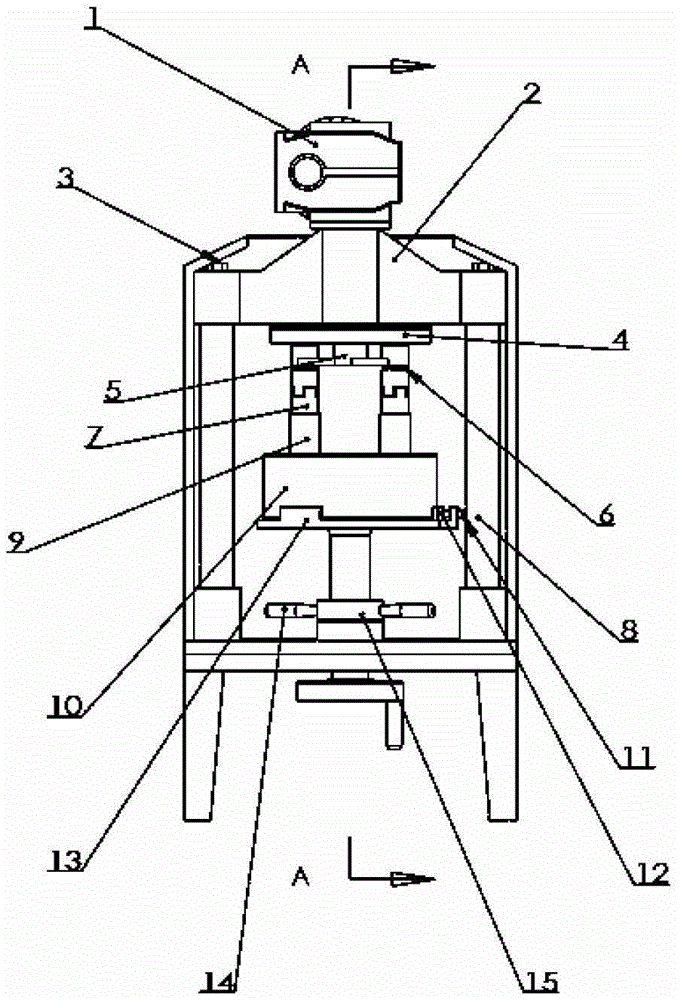

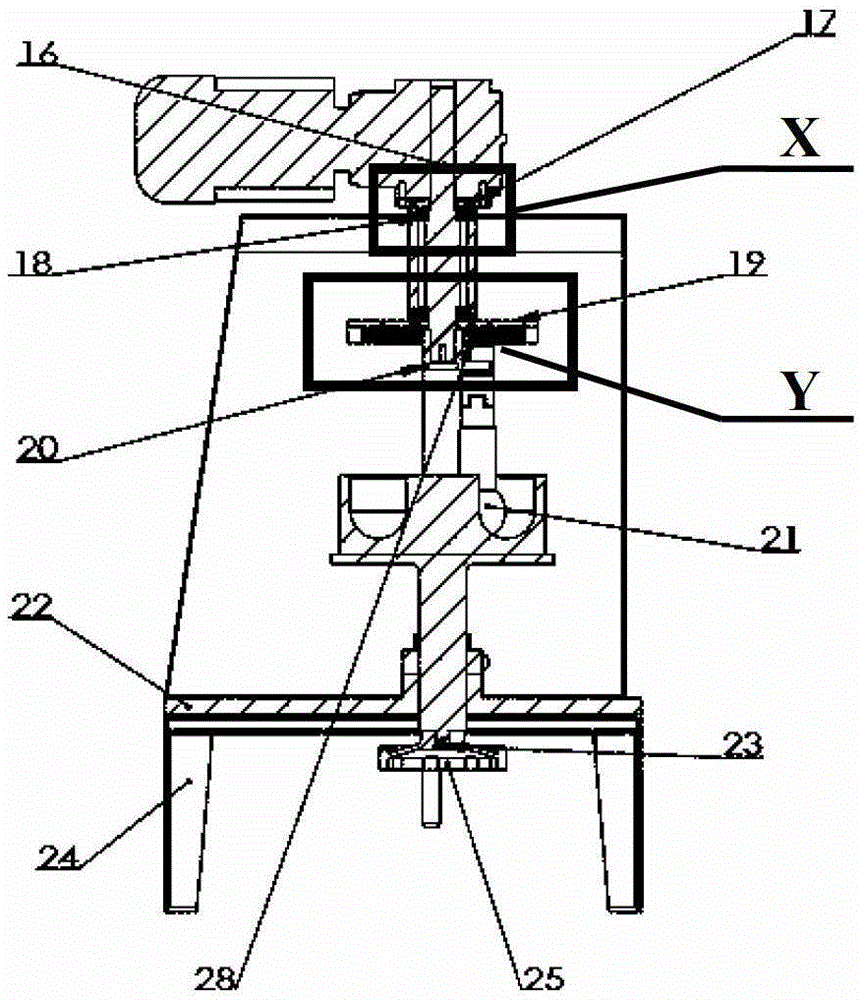

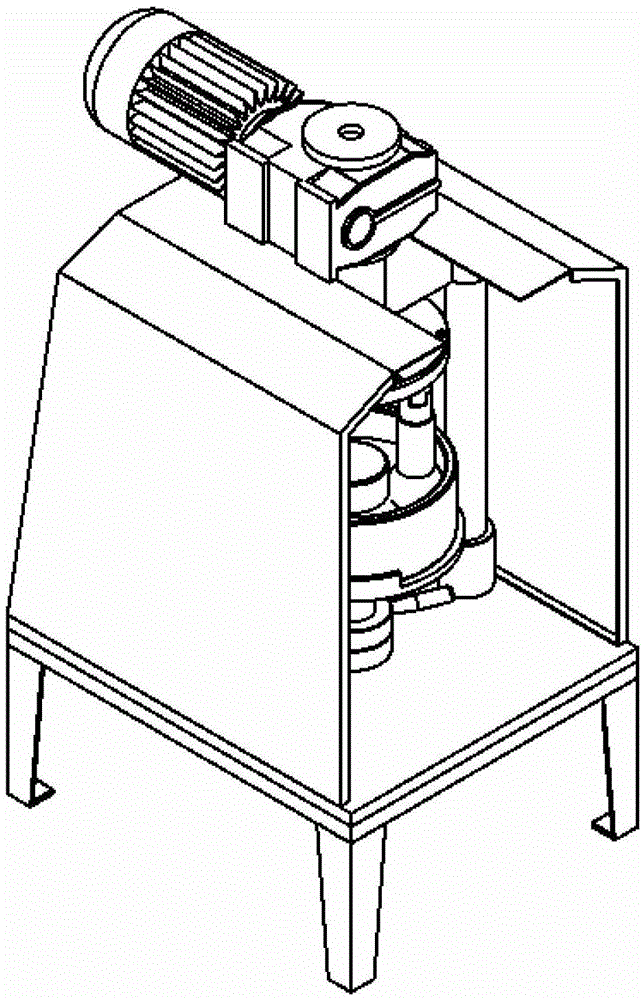

A bowl grinder

A grinding machine and mortar technology, which is applied in the field of grinding machine improvement, can solve the problems of low efficiency, low yield rate, and insufficient fine grinding degree of manual mortars, and achieve improved grinding efficiency, high yield rate, and increased area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The present invention provides a bowl grinder as described above, wherein the mortar is made of corundum with a purity of 99%. The radius of the hammer head 211 is R 1 , The radius of the semicircular bottom of the circular orbit 102 is R 2 , R 2 -R 1 =0.5mm. When the spherical hammer head 211 is ground in the annular track 102, the gap between the semicircular inner surface of the bottom of the annular track 102 and the lower half spherical surface of the hammer head 211 is filled with material. The above mortar has a relatively large volume and can be used to grind 50 grams of materials.

Embodiment 2

[0083] The present invention provides a bowl grinder as described above, wherein the mortar is made of wear-resistant ceramics. The radius of the hammer head 211 is R 1 , The radius of the semicircular bottom of the circular orbit 102 is R 2 , R 2 -R 1 =0.01mm. When the spherical hammer head 211 is ground in the annular track 102, the gap between the semicircular inner surface of the bottom of the annular track 102 and the lower half spherical surface of the hammer head 211 is filled with material. The above mortar has a relatively large volume and can be used to grind 50 grams of materials.

Embodiment 3

[0085] The present invention provides a bowl grinder as described above, wherein the mortar is made of corundum with a purity of 99%. The radius of the hammer head 211 is R 1 , The radius of the semicircular bottom of the circular orbit 102 is R 2 , R 2 -R 1 =0.2mm. When the spherical hammer head 211 is ground in the annular track 102, the gap between the inner surface of the bottom of the annular track 102 and the lower half spherical surface of the hammer head 211 is filled with materials.

[0086] The bowl grinder provided in Examples 1-3 of the present invention was used to grind calcium carbonate, and the grinding results are shown in Table 1.

[0087] Table 1 Grinding effect data of Examples 1 to 3

[0088]

[0089] According to the data in Table 1, compared with the existing manual mortar and motorized grinder, the bowl grinder provided by the present invention has higher grinding efficiency, and the bowl grinder of the present application can perform fine grinding. Grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com