Lip for producing wide aluminium alloy cast-rolled slab

An aluminum alloy and casting nozzle technology, which is applied to the casting nozzle structure field used in the production of wide-width aluminum alloy slabs by casting and rolling method, can solve the problem that it is difficult to ensure that the heat field of the melt flow at the exit of the casting nozzle is uniform and reasonable. The problems of uniform melt flow and heat field at the outlet of the nozzle can achieve the effect of simple structure, low cost and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

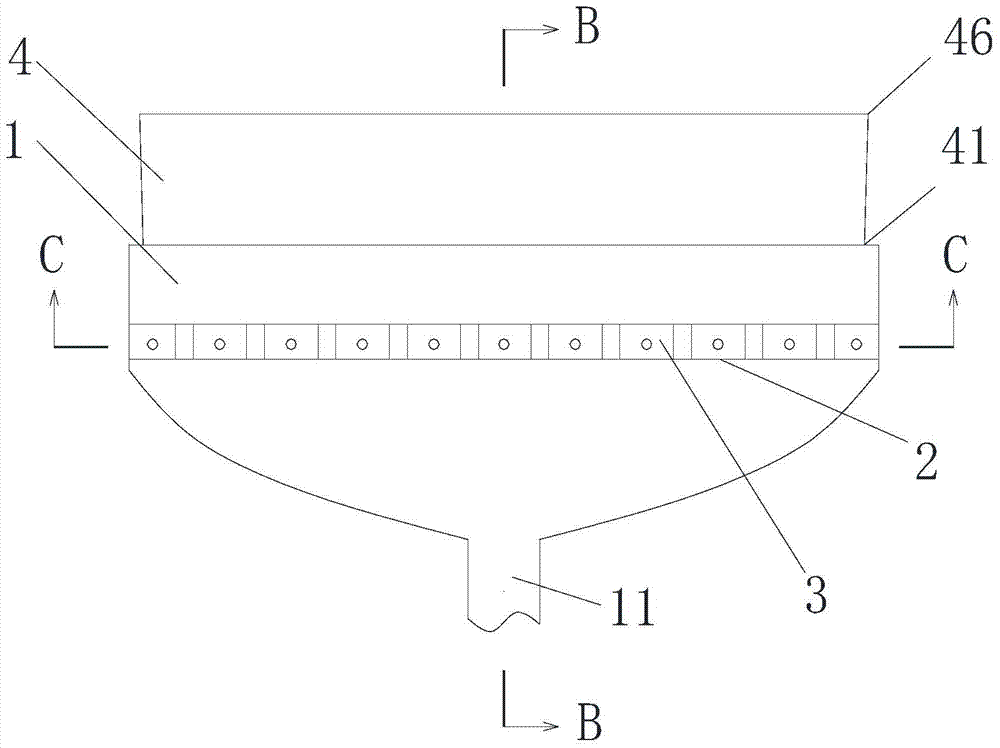

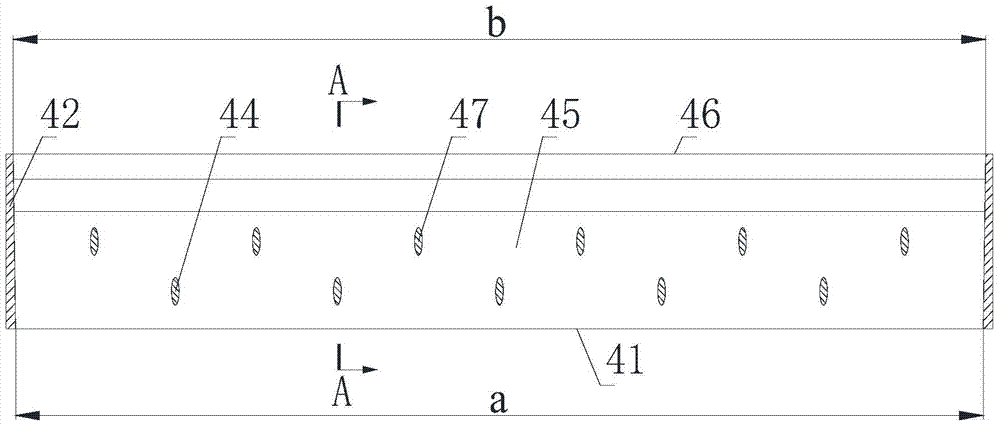

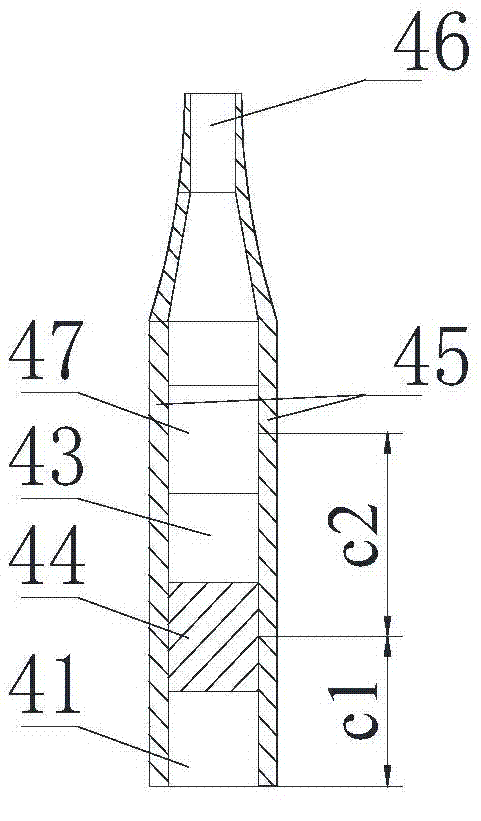

[0031] a kind of like figure 1 , figure 2 The casting nozzle for producing wide-width aluminum alloy casting and rolling slabs shown is mainly composed of upper and lower box plates 45 and side stoppers 42 butted together, and a melt-shaped joint is formed between the upper and lower box plates 45. Cavity 43, one end of melt cavity 43 is inlet 41, and the other end is provided with outlet 46, is provided with a plurality of support blocks in melt cavity 43, and each support block is fixedly connected between upper and lower box plate 45 Between, the width a of the inlet 41 of the nozzle is slightly smaller than the width b of the outlet 46 of the nozzle (20mm smaller), and the width a of the inlet 41 of the nozzle is 1860mm, and the width b of the outlet 46 of the nozzle is 1880mm , and the width of the nozzle itself is 1900mm.

[0032] In the nozzle 4 of the present embodiment, each supporting block is an elliptical columnar supporting block (see figure 2), and the long...

Embodiment 2

[0035] A casting nozzle for producing wide-width aluminum alloy casting and rolling slabs according to the present invention is basically the same in structure as that of the casting nozzle in Example 1, but the width of the inlet of the casting nozzle in this embodiment is 2000mm, and the casting nozzle The width of the outlet is 2020mm, and the width of the nozzle itself is 2040mm.

[0036] In addition, in this embodiment, there are 8 elliptical support blocks in the front row, 9 elliptical support blocks in the front row, and the distance between two adjacent support blocks in each row is equal.

[0037] The surface quality of the aluminum alloy cast-rolled slabs produced by the casting nozzles of the above-mentioned embodiments of the present invention is good, the convexity of the plates is controlled within 0.2% to 0.8% of the plate thickness, the edge difference is ±0.03mm, and the edges and centers of the plates are The microstructure of the parts tends to be consisten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com