Double-nut distance-adjusting device for extrusion tablet machine

A technology of extrusion tablet press and distance adjustment device, which is applied in the field of distance adjustment device, can solve the problems of reducing the accuracy of roller distance adjustment, affecting the distance adjustment accuracy, and only stopping to adjust the distance, so as to avoid the rotation and wear of the lead screw. , Improve the precision of distance adjustment and reduce the effect of the amount of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

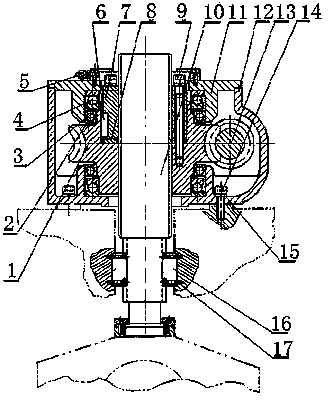

[0014] Such as figure 2 As shown, the double-nut distance adjusting device is mainly composed of a housing 12, a housing gland 11, a worm gear mechanism, a lead screw 10, a distance adjusting nut 7 and a distance adjusting pad 8, and the worm gear mechanism is installed in the housing 12. The housing gland 11 and the housing 12 form a closed cavity, the worm gear nut 1 of the worm gear mechanism is threadedly connected with the lead screw 10, the distance adjusting nut 7 and the distance adjusting pad 8 are connected with the worm gear nut 1 through the first screw 9, and the distance adjusting The nut 7 is threadedly connected with the lead screw 10, the casing 12 is fixedly connected with the frame, the lead screw 10 is fixedly connected with the roller bearing, the lead screw 10 is connected with the frame by the second key 16, and the second key 16 is connected by the third screw 17 Fixedly connected on the frame, the lead screw 10 has a keyway, the second key 16 can only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com