Disk drive having reduced variation of disk surface lubricant layer thickness

A disk drive and lubricant layer technology, applied in the recording of information on the disk, driving/moving the recording head, vehicle speed control/regulation/indication, etc., can solve the problems of interfering with reading data and increasing the disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

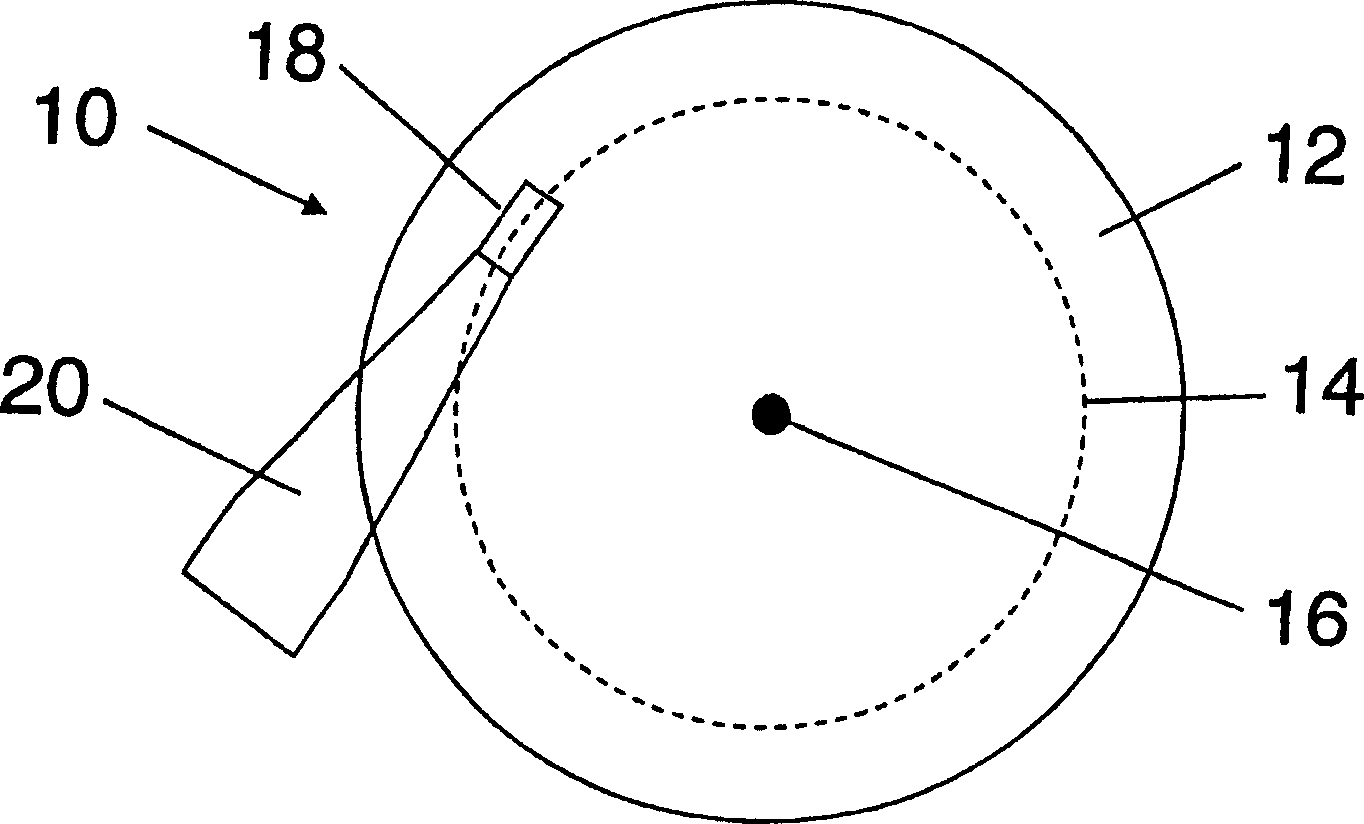

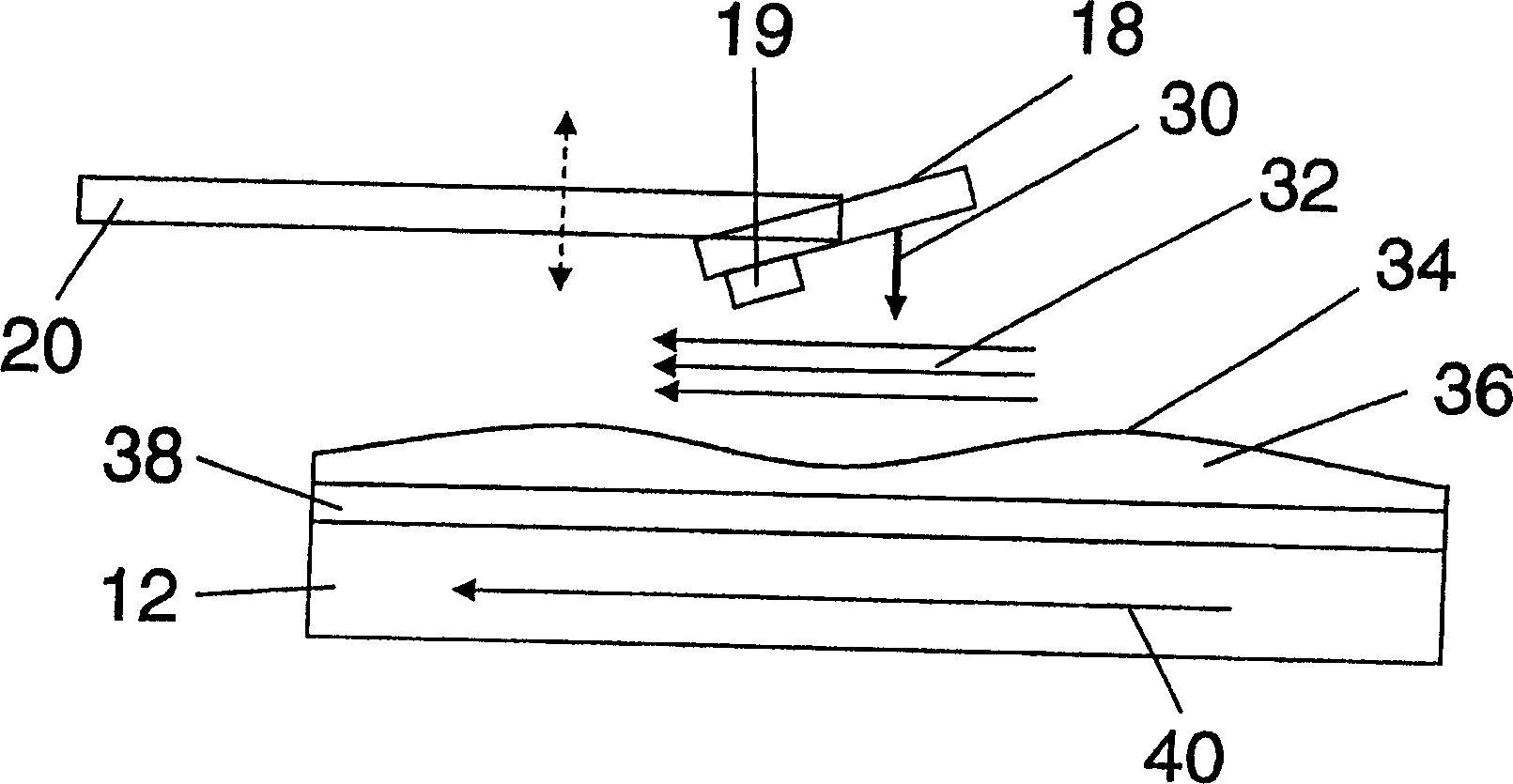

[0013] figure 1 A top view of a disk drive 10 is shown schematically. Disk drive 10 includes a disk 12 . One includes a read-write magnetic head 19 (such as image 3 shown, not in figure 1 upper) slider 18. Disk 12 rotates about axis 16 and has a layer 38 of magnetic recording material (such as image 3 shown). In magnetic recording material are multiple radially spaced tracks, one of which is figure 1 Expressed as 14 in. Slider bar 18 is positioned on track 14 such that magnetic head 19 is enabled to read data from or write data to track 14 . The slider 18 is a part of the magnetic head device 20 . The magnetic head device 20 includes (not in figure 1 appears in ) is used to position the head 19 at the desired radial position relative to the disk (ie, on the centerline of the selected disk).

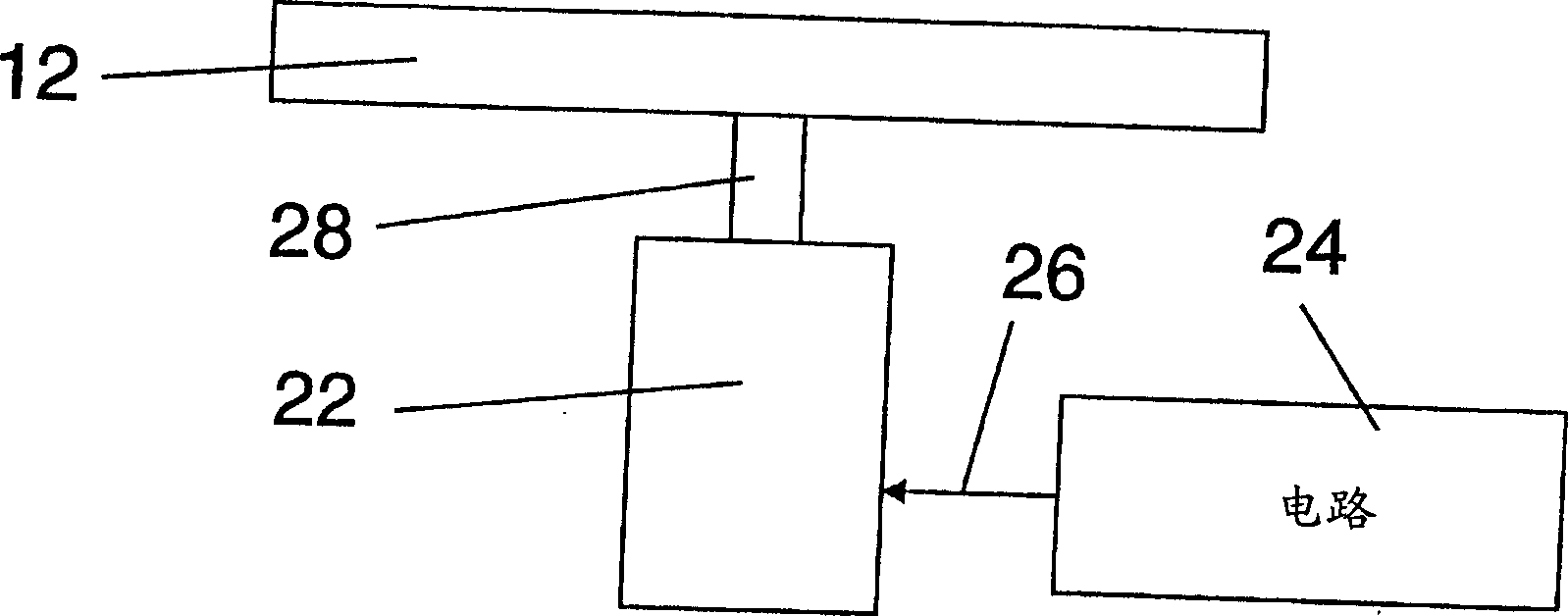

[0014] figure 2 outlines the figure 1 Side view of a disk drive in . A motor 22 is coupled to the disk 12 via a shaft 28 . A circuit 24 is controllably connected to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com