Corrugated paper material arrangement table

A corrugated paper and material table technology, applied in thin material handling, stack receiving device, transportation and packaging, etc., can solve problems such as difficulty in adapting to diversified production, and achieve the effect of simple structure, convenience and neatness, and reduced occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

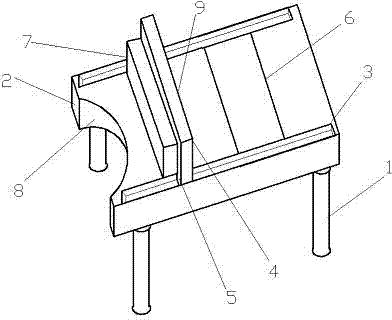

[0012] Such as figure 1 As shown, a corrugated paper monolithic table includes a bracket 1, a panel 2 is arranged on the bracket 1, a chute 1 is arranged on both sides of the panel 2, a positioning block 4 is arranged on the panel 1, and sliders are arranged at both ends of the positioning block 4 5 is set in the chute 3, there is a certain gap between the positioning block 4 and the panel 2, a stopper 7 is set on one side of the positioning block 4, a positioning line 6 is set on the panel 2, and a protective layer 9 is set on the positioning block 4 , the material of the monolithic platform is wood, and one side of the panel 2 is provided with an arc-shaped monolithic area 8 .

[0013] The beneficial effect of adopting the above technical solution is: according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com