Traction rope for elevator device

A technology for hoisting ropes and elevators is applied in the field of hoisting ropes to achieve the effects of reducing rotational torque, reducing the volume of the main engine, and reducing manufacturing costs and construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

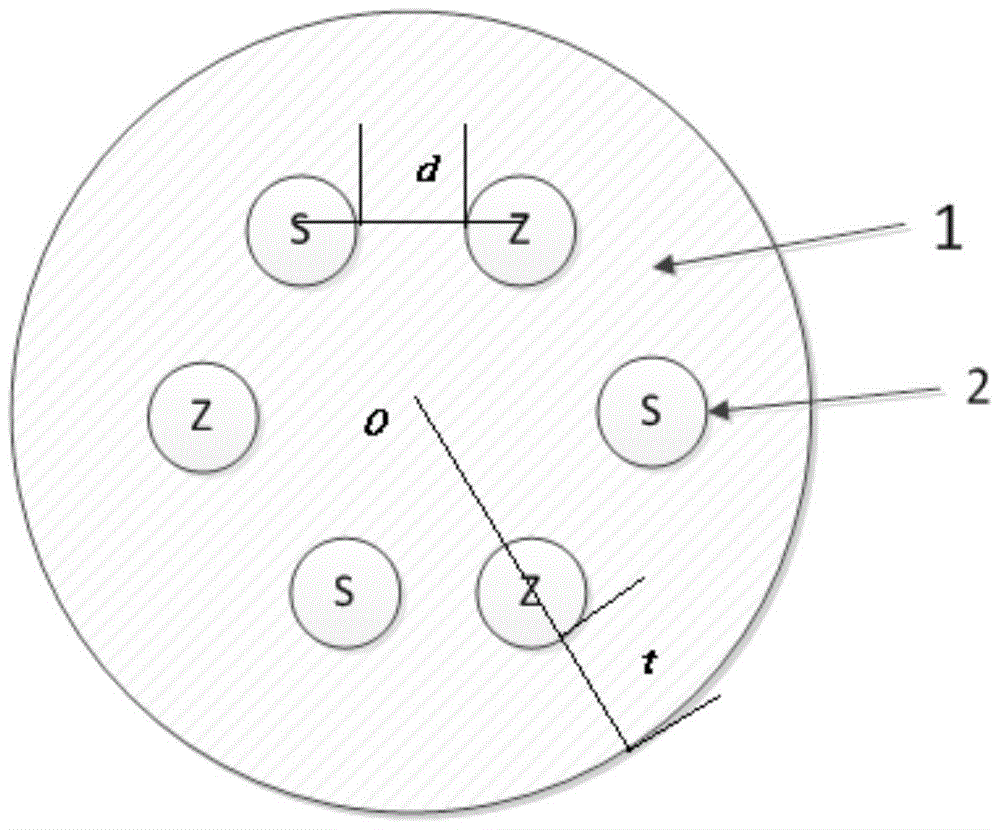

[0040] Such as figure 1 As shown in the figure, the traction rope for the elevator device shown in the figure is composed of an elastic body 1 constituting the main body of the traction rope and six independent bearing bodies 2. The cross section of the elastic body is circular, and the non-metallic elastic Material, specifically polyurethane rubber.

[0041] Six independent carriers 2 are directly embedded in the elastic body 1 and are completely covered by the elastic body 1 . Considering the isotropy and compact structure of the traction rope, the six independent bearing bodies 2 are evenly distributed on the same circumference, and the angle formed by the center of the adjacent independent bearing body 2 and the center of the elastic body 1 is 60° .

[0042]Each independent carrier 2 is made of metal material, specifically, each independent carrier 2 is made of high-strength carbon steel wire twisted into a steel wire rope with a diameter of 0.5mm-3.5mm, specifically 1+9...

Embodiment 2

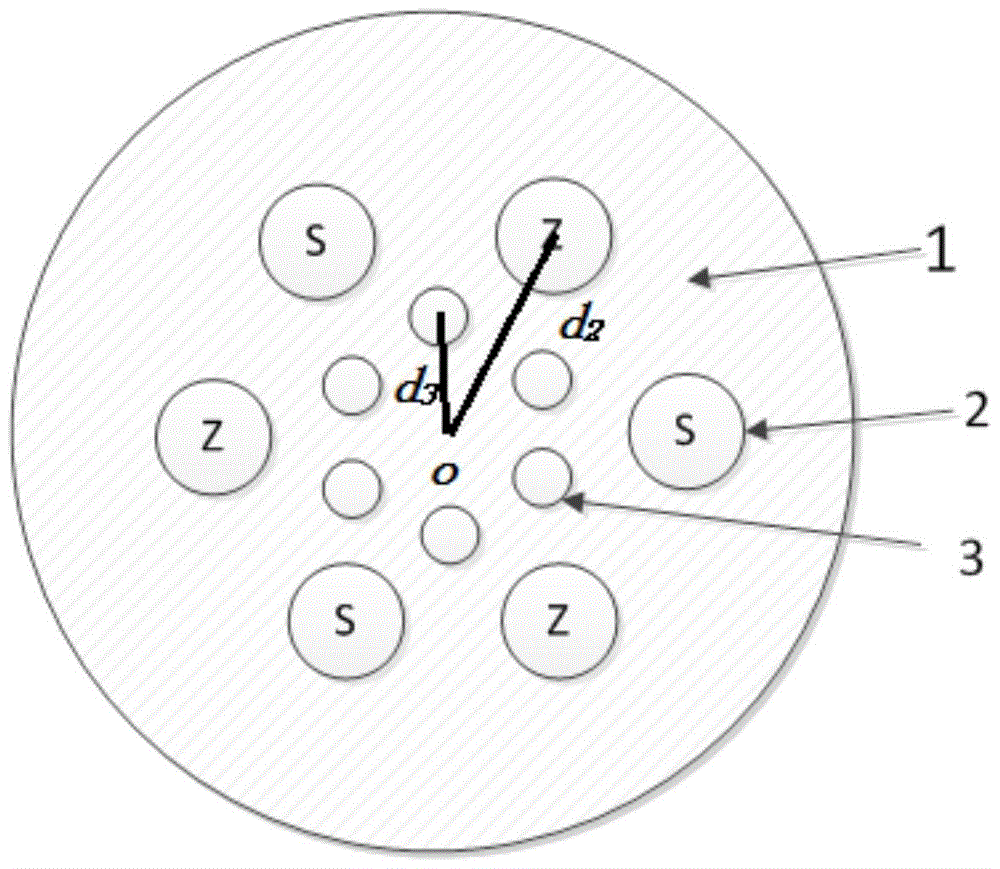

[0046] In order to increase the breaking force of the traction rope and provide support for the independent carrier 2 of the outer layer, such as figure 2 As shown, all the independent carriers of this embodiment are distributed in two layers of concentric circles in the radial direction in the elastic body 1, and the independent carriers of each layer are evenly spaced on the same circumference. Considering the compactness of the structure, the independent The diameter of the carrier body 3 is smaller than the diameter of the independent carrier body 2 of the outer layer, and every adjacent two independent carrier bodies 3 in the independent carrier body 3 that are evenly spaced on the same circumference of the outer layer form a trough with the center of the cross section of the elastic body 1, The independent carriers 2 in the inner layer that are evenly spaced on the same circumference fall into these troughs respectively.

[0047] The distance d from the center of each i...

Embodiment 3

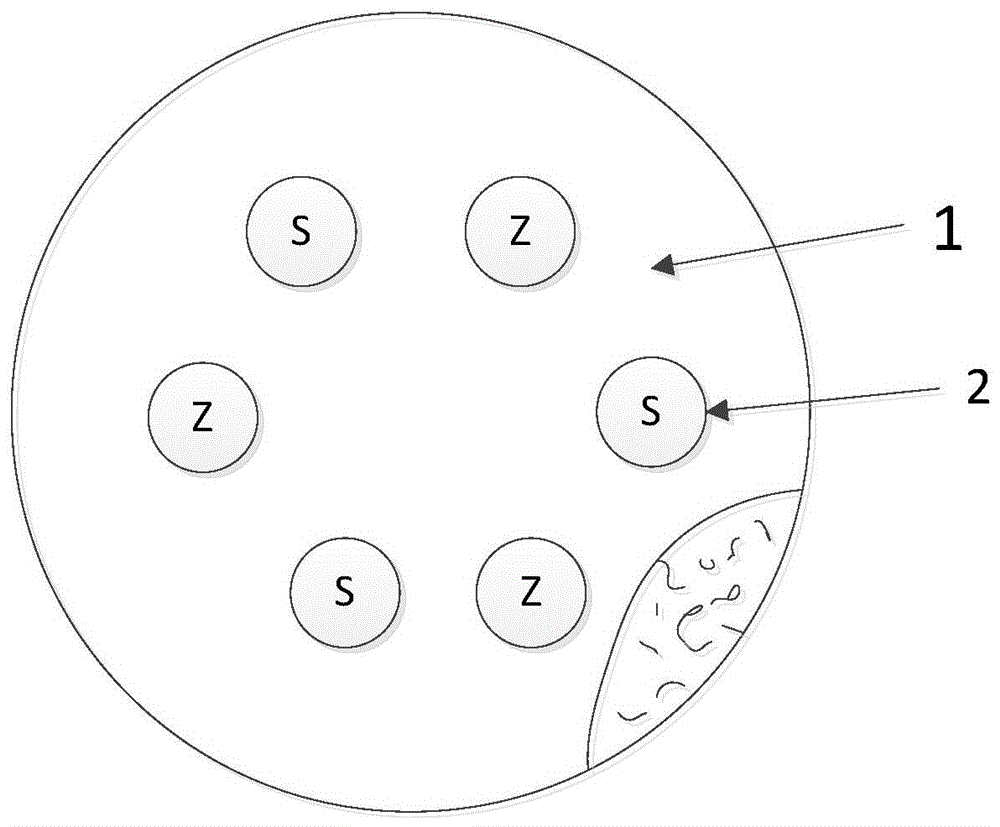

[0049] Such as image 3 As shown, the difference between the traction rope for the elevator device of this embodiment and Embodiment 1 and Embodiment 2 is that the elastic body 1 is made of neoprene rubber reinforced with nylon short fibers, which can enhance the wear resistance of the elastic body, and can Effectively prolong the service life of the traction rope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com