A kind of preparation method of ysz-lsm composite thermal barrier coating material

A technology of thermal barrier coating and composite powder is applied in the field of preparation of YSZ-LSM composite thermal barrier coating materials, which can solve the problems of sintering and high thermal conductivity, and achieve good sintering resistance and coating thermal conductivity. Low, even compounding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

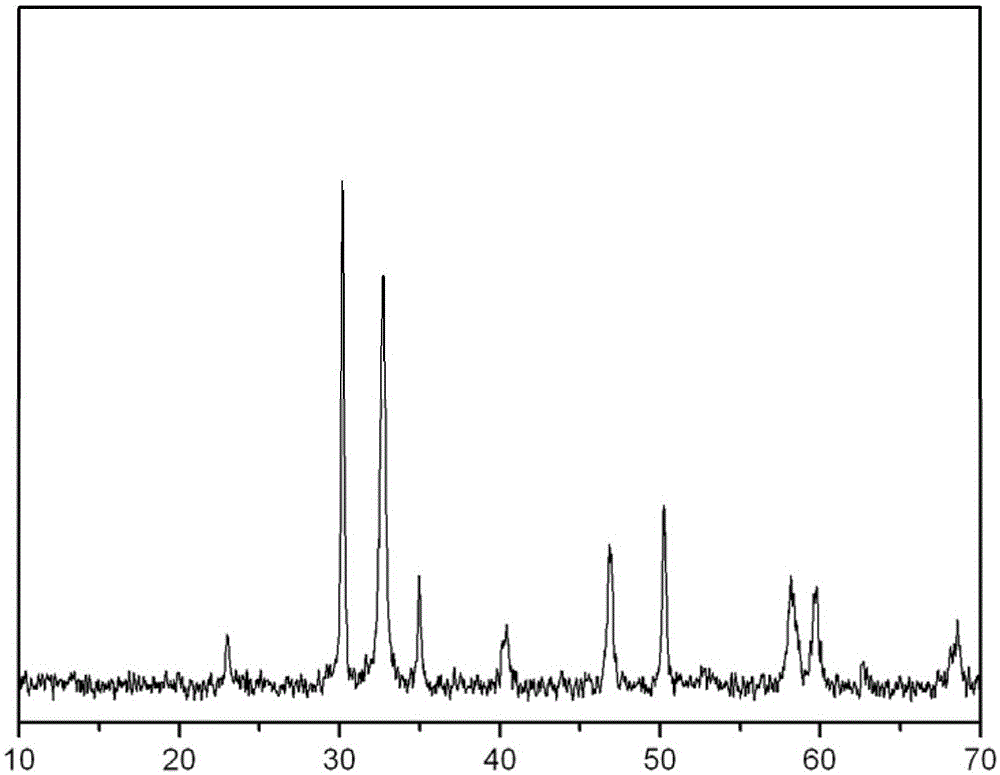

[0011] The specific embodiment of the present invention proposes a preparation method of YSZ-LSM composite thermal barrier coating material with low thermal conductivity and high sintering resistance. The composite powder synthesis steps mainly include: preparation of raw material solution, synthesis of precursor powder and heat treatment process. Preparation of YSZ-LSM Thermal Barrier Coating Composite Powder With LSM powder as the core of the composite powder, YSZ as the coating layer, and urea as the combustion agent, the YSZ-LSM composite powder was prepared by a low-temperature self-combustion in-situ synthesis method. YSZ is Y 2 O 3 Stable ZrO 2 The abbreviation of LSM is La 1-x Sr x MnO 3 The specific steps are as follows:

[0012] Step 1, using Zr (NO 3 ) 4 and Y(NO 3 ) 3 The solution was used as a metal ion source to synthesize YSZ, and the molar ratio was 97:3 to 90:10 to prepare Zr (NO 3 ) 4 and Y(NO 3 ) 3 Mix the solution, and then make the mixture ac...

Embodiment 1

[0018] Formulated Zr(NO 3 ) 4 and Y(NO 3 ) 3 solution, the reagent is Zr (NO 3 ) 4 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O, the experimental water was deionized water. Weigh 22gZr(NO 3 ) 4 ·6H 2 O and 20gY (NO 3 ) 3 ·6H 2 O, added to 2L deionized water and fully stirred to dissolve, after mixing evenly, add LSM powder to form a mixture, the ratio of LSM mass to the theoretical mass of YSZ to be generated is 4:6, and then ultrasonically treated for 30 minutes. According to urea and solution metal ion Zr 4+ and Y 3+ The molar ratio of the total amount is 6:1. The urea is weighed and added to the above mixed solution, and then the mixture is transferred to an evaporating dish and heated and evaporated at 400 ° C to make the mixed solution gelatinized until it forms a colloidal shape with LSM as the dispersed phase. Continue to heat until burning to obtain primary powder. The primary powder was calcined at 1000° C. for 2 hours to obtain YSZ-LSM composite powder.

[0019...

Embodiment 2

[0021] The YSZ-LSM composite powder obtained by the combustion method was mixed with 2 times the mass of deionized water to prepare a slurry, and the YSZ-LSM composite powder mass 10wt.% binder K30 glue and appropriate amount of other auxiliary agents were added to the slurry. Including polyethylene glycol, n-octanol, and tackifier, after 12 hours of ball milling, it is sent to a centrifugal atomization dryer for spray granulation. The feed rate was 500 mL / h, the centrifugal speed was 10500 rpm / min, the inlet and outlet temperatures were 350°C and 150°C, respectively, and the drying gas was N 2 . The collected powder was heat-treated in a muffle furnace at 1000° C. for 2 hours to obtain spherical YSZ-LSM granulated powder material. Then the YSZ-LSM granulated powder was sprayed onto the metal substrate by GTV atmospheric plasma spraying equipment to obtain the YSZ-LSM thermal barrier coating.

[0022] Using the technical solution provided by this specific embodiment, YSZ-LSM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com