A twisting even twister

The technology of a twist leveler and main body is applied in the field of textile equipment, which can solve the problems of poor consistency of spinning tension, poor yarn leveling effect, and unsatisfactory strength retention rate, so as to achieve low yarn loss and consistent spinning tension. The effect of good sex and convenient threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

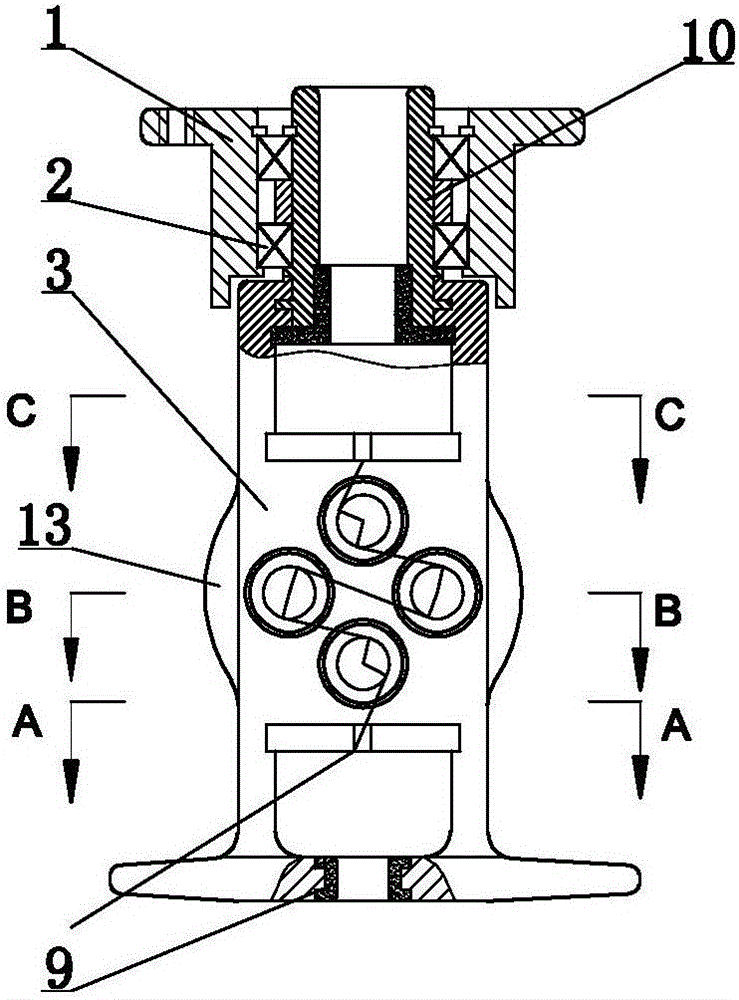

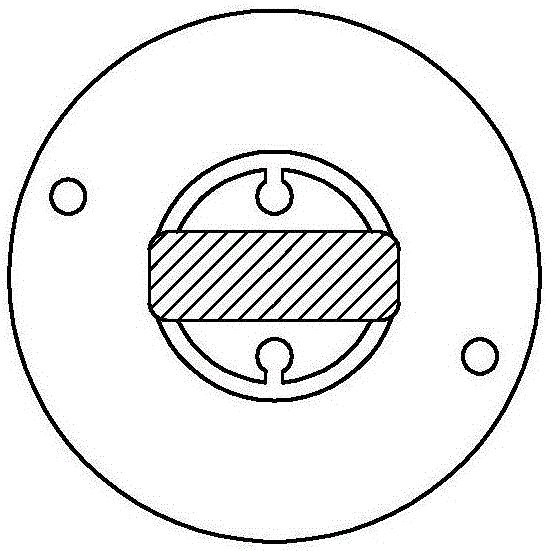

[0018] Such as figure 1 , 2 , 3, 4, and 5 show a kind of twist leveler, including a mounting base 1 and a twist leveler main body 3 with a hole in the center, and the upper part of the twist leveler main body 3 is embedded in the mounting base 1 through a bearing A2 , the upper part of the twister main body 3 is connected with the bearing A2 through an inlay 10, the middle part of the twister main body 3 is provided with a twisting uniform structure, the lower part of the twister main body 3 is provided with an outer yarn porcelain eye 8, and the lower part of the twister main body The middle is provided with inner yarn porcelain eye 9.

[0019] The twisting and leveling structure includes four godet shafts 5, the godet shafts 5 are horizontally arranged in the middle part of the twister main body 3, the godet shafts 5 are arranged on the twister main body 3 through the bearing B6, and the godet shafts 5 The guide wheels 4 are fixedly installed at both ends, and the arc-shap...

Embodiment 2

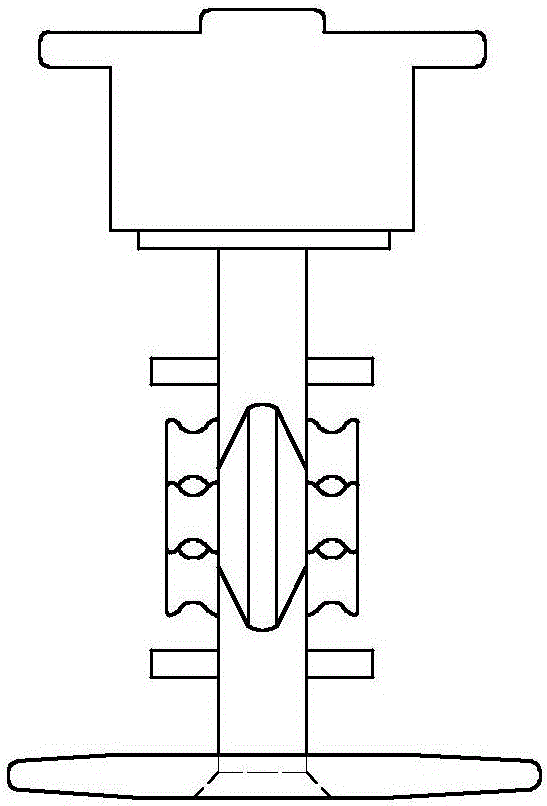

[0023] Such as Figure 6 , 7 , 8, 9 and 10, the difference between the present embodiment and embodiment 1 is that the twisting and leveling structure includes three guide wheels 15, and the guide wheels 15 are vertically arranged in the middle part of the twist leveling device main body 3, Two pressure wheels are placed between the guide wheels 15, and the two pressure wheels are fixedly mounted on the detachable insert body 14.

[0024] During use, the yarn moves through the guide wheels 15, and the two pressure wheels on the insert body 14 are pressed between the three guide wheels 15 at intervals, so that the yarn becomes zigzag, and the yarn is wound at a large angle, evenly Twisting performance is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com