Water distribution valve spool of water jet loom

A water diversion valve core and water jet loom technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the misalignment between the axis of the stainless steel water diversion valve and the water channel hole of the ceramic pipe, the shutdown of the loom, and the failure to supply normally Needle group and other problems to achieve the effect of ensuring normal water supply demand and reliable and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

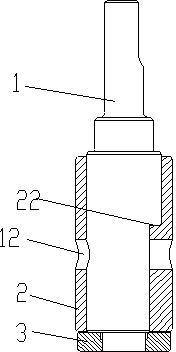

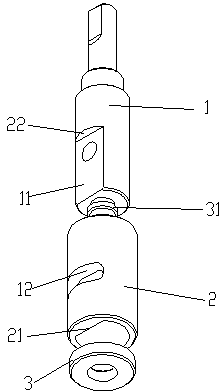

[0013] The water diversion valve core of the water jet loom includes a water diversion shaft 1 and a water diversion jacket 2, the water diversion shaft 1 is fixedly arranged in the water diversion jacket 2, and the water diversion shaft and the water diversion jacket are respectively provided with holes 12 connected to each other . The axial side of the water distribution shaft 1 is provided with a first limiting plane 11, and the inside of the water dividing sleeve is provided with a second limiting plane 21 opposite to the first limiting plane. The first limiting plane and the second limiting plane The contact connection prevents the water distribution shaft from rotating relative to the water distribution sleeve.

[0014] The ends of the first limiting plane 11 and the second limiting plane 21 are respectively provided with opposite limiting steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com