Construction method for adjustable triangular bracket

A technology of triangular brackets and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., which can solve the problems of difficult handling, complicated setting of embedded parts, low reuse rate, etc., and achieve high economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

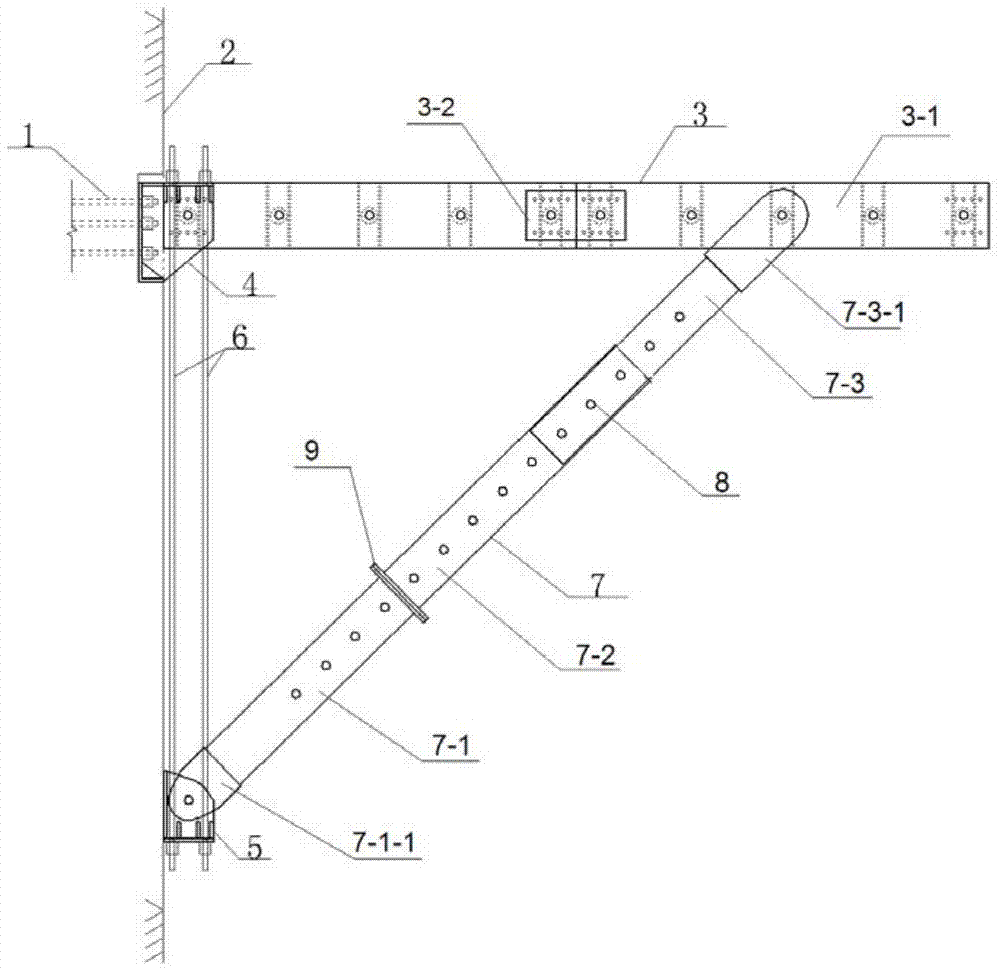

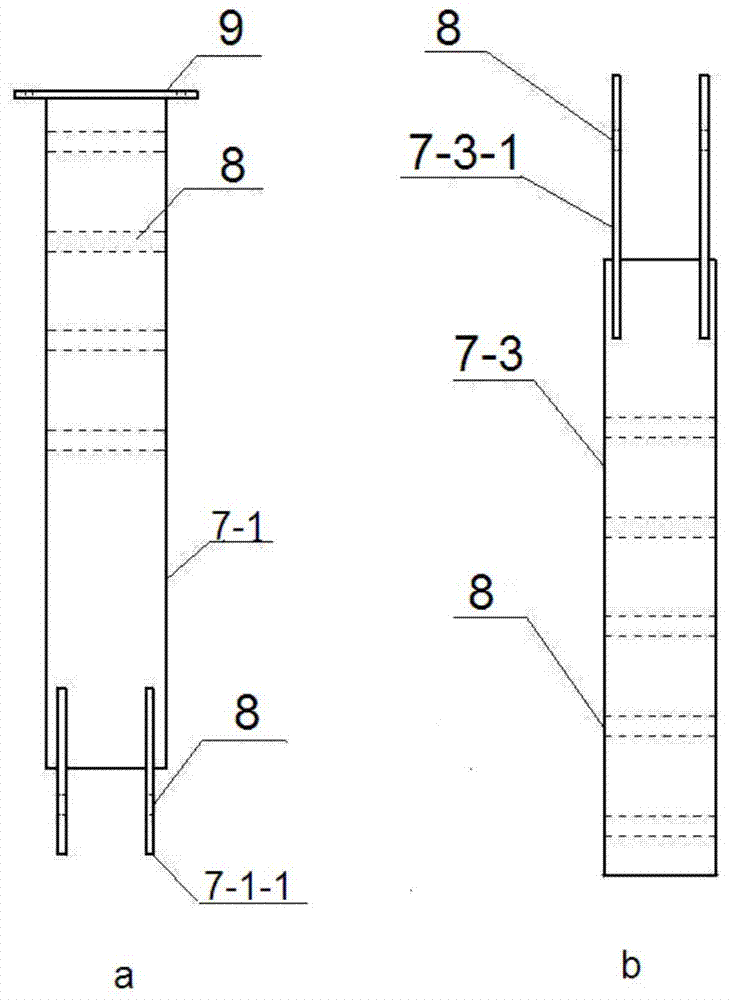

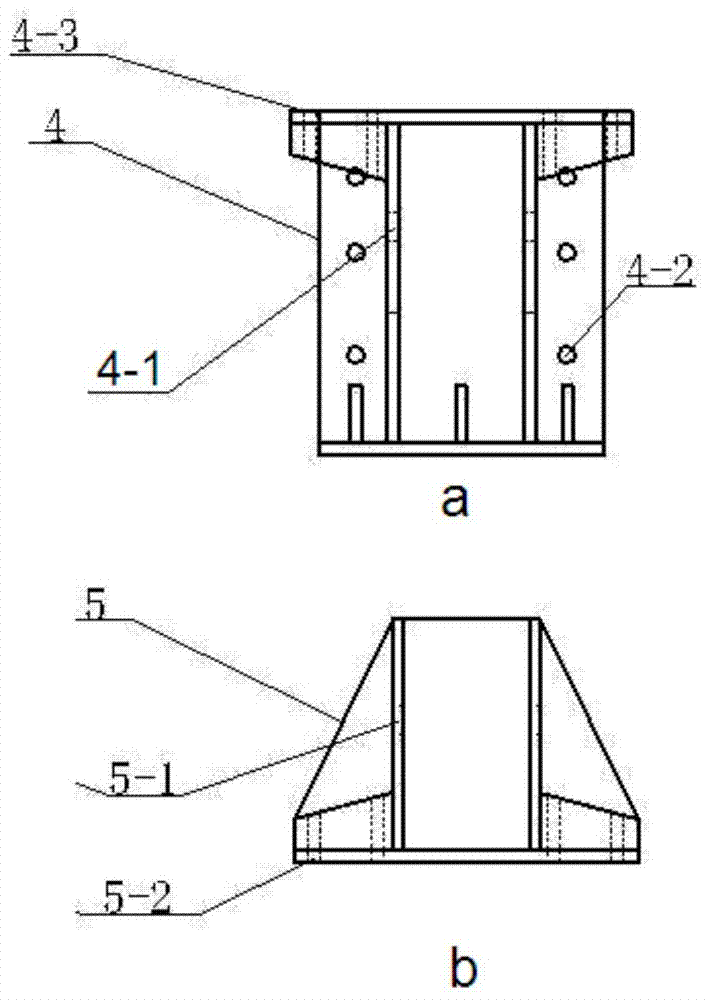

[0024] Such as Figure 1 ~ Figure 3 As shown, an adjustable triangular bracket includes a horizontal beam 3, an upper supporting plate 4, a lower supporting plate 5, a suspension rod 6 and a diagonal rod 7. Among them, the upper supporting plate 4 is anchored to the outer surface 2 of the pier column through the tie rod 1; one end of the horizontal beam 3 is connected to the upper supporting plate 4, and the other end is connected to the diagonal bar 7 at the inner position. Horizontal beam is made up of two cross bars 3-1 and splint 3-2, and cross bar 3-1 is connected by bolt with splint 3-2. The inclined bar 7 is composed of a bottom inclined bar 7-1, an extension bar 7-2 and a top inclined bar 7-3, wherein the bottom inclined bar 7-1 and the extension bar 7-2 are connected by a flange 9; the extension bar 7-2 Connect with the steel pin by pin hole 8 between the jacking rod 7-3. One end of the bottom inclined rod 7-1 is provided with a lower ear plate 7-1-1 with a pin hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com