Comb tooth type automobile carrier and mechanical equipment for parking automobile

A car carrier and comb technology, which is applied to the buildings, building types, buildings, etc. where cars are parked, can solve the problems of poor adaptability of the car carrier to the road surface, complex structure of the jacking mechanism, weak driving force, etc., to achieve The lifting structure is ingeniously designed, the driving force of walking is improved, and the assembly is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

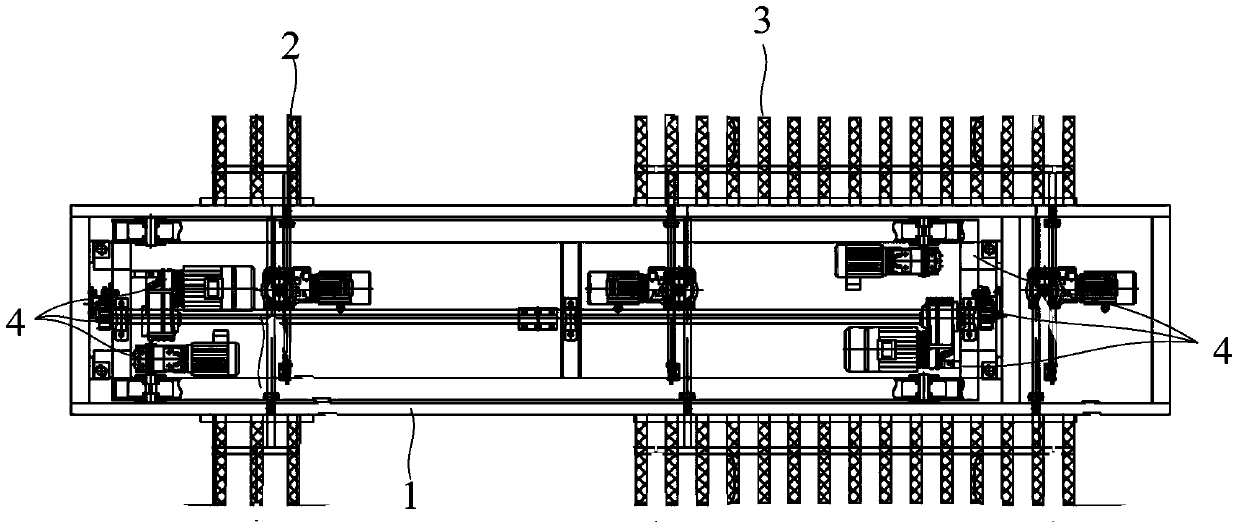

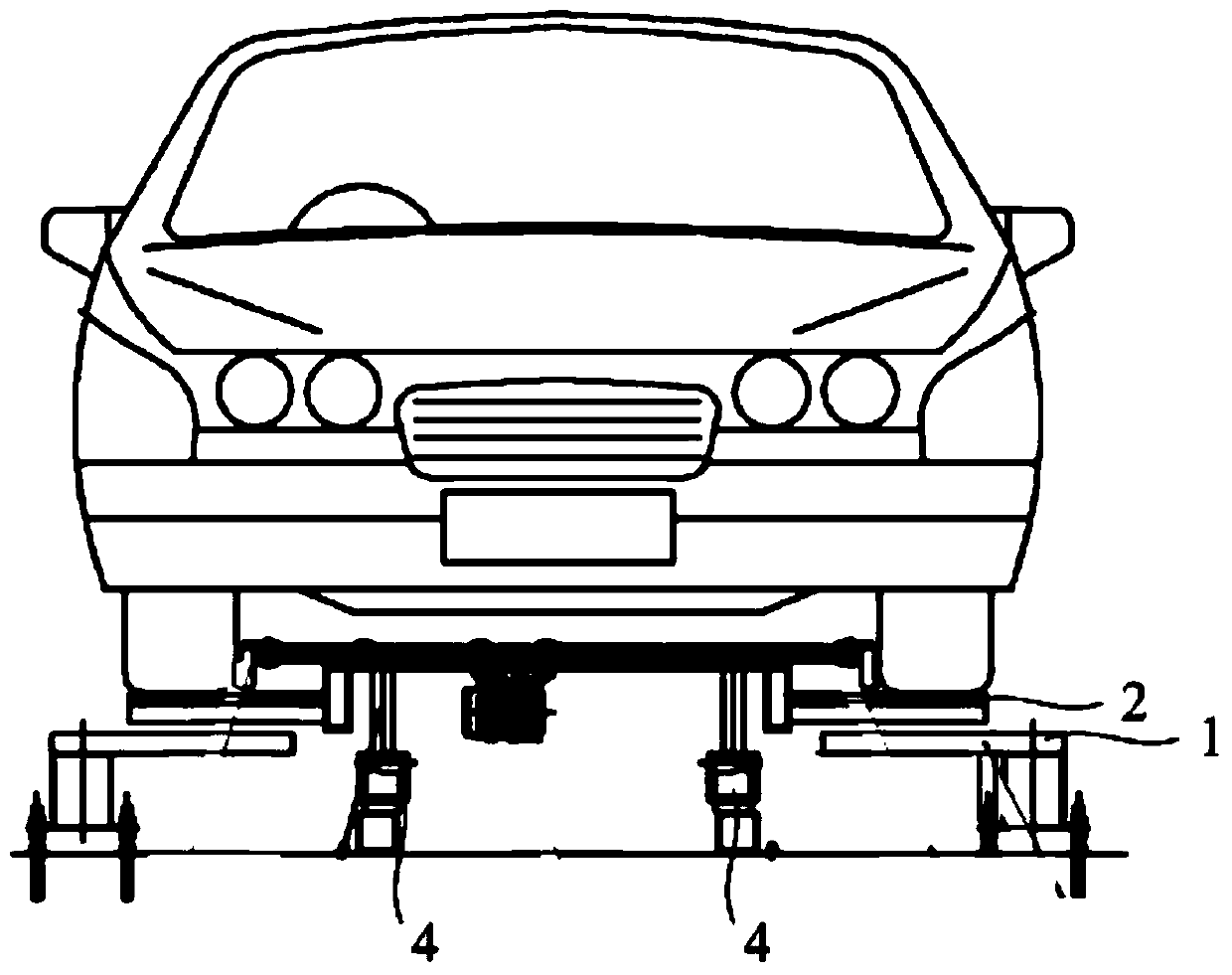

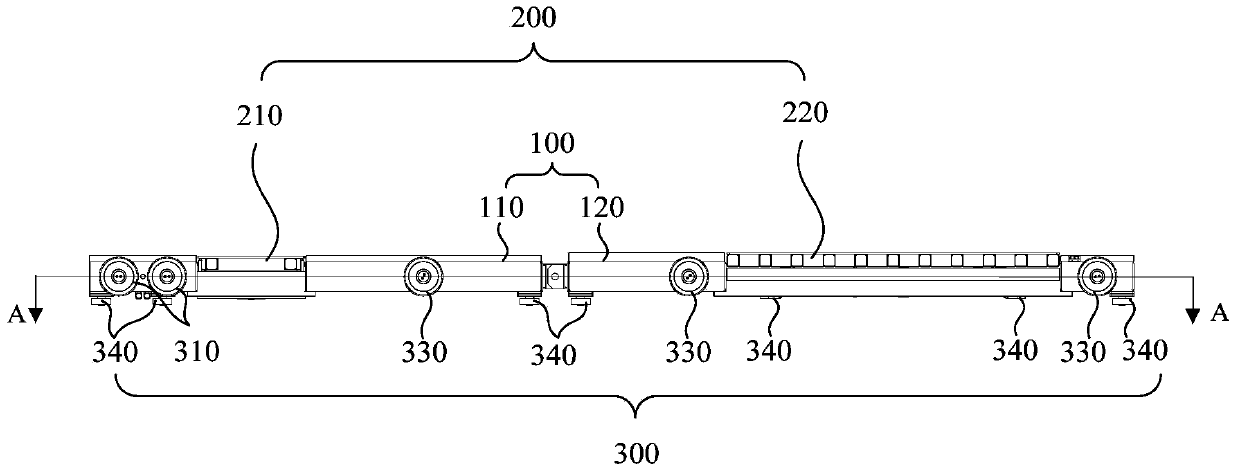

[0048] The embodiment of the present invention provides a kind of mechanical parking equipment, referring to Figure 3-5 , which includes a comb type car carrier. Wherein the comb-toothed vehicle carrier comprises: vehicle frame 100; Comb-tooth frame 200, is positioned on described vehicle frame 100 and is connected to described vehicle frame 100 liftably; Travel mechanism 300, is connected on described vehicle frame 100 both sides And set oppositely; the jacking mechanism 400 is connected to the comb rack 200 .

[0049] In this example, refer to Figure 5 and combine Figure 6-7 , the jacking mechanism 400 is located at the bottom of the comb frame 200, and the jacking mechanism 400 includes: at least one set of jacking driving parts 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com