Large-diameter long pipe curtain construction method for shallowly-buried large-span under-tunnel-passing architectural structure

A construction method and large-diameter technology, applied in tunnels, tunnel linings, underground chambers, etc., to achieve clear layers of rammed earth and reduce the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the present invention, each step of the present invention is described in detail through the following examples, but the protection scope of the present invention is not limited to the description of the following examples.

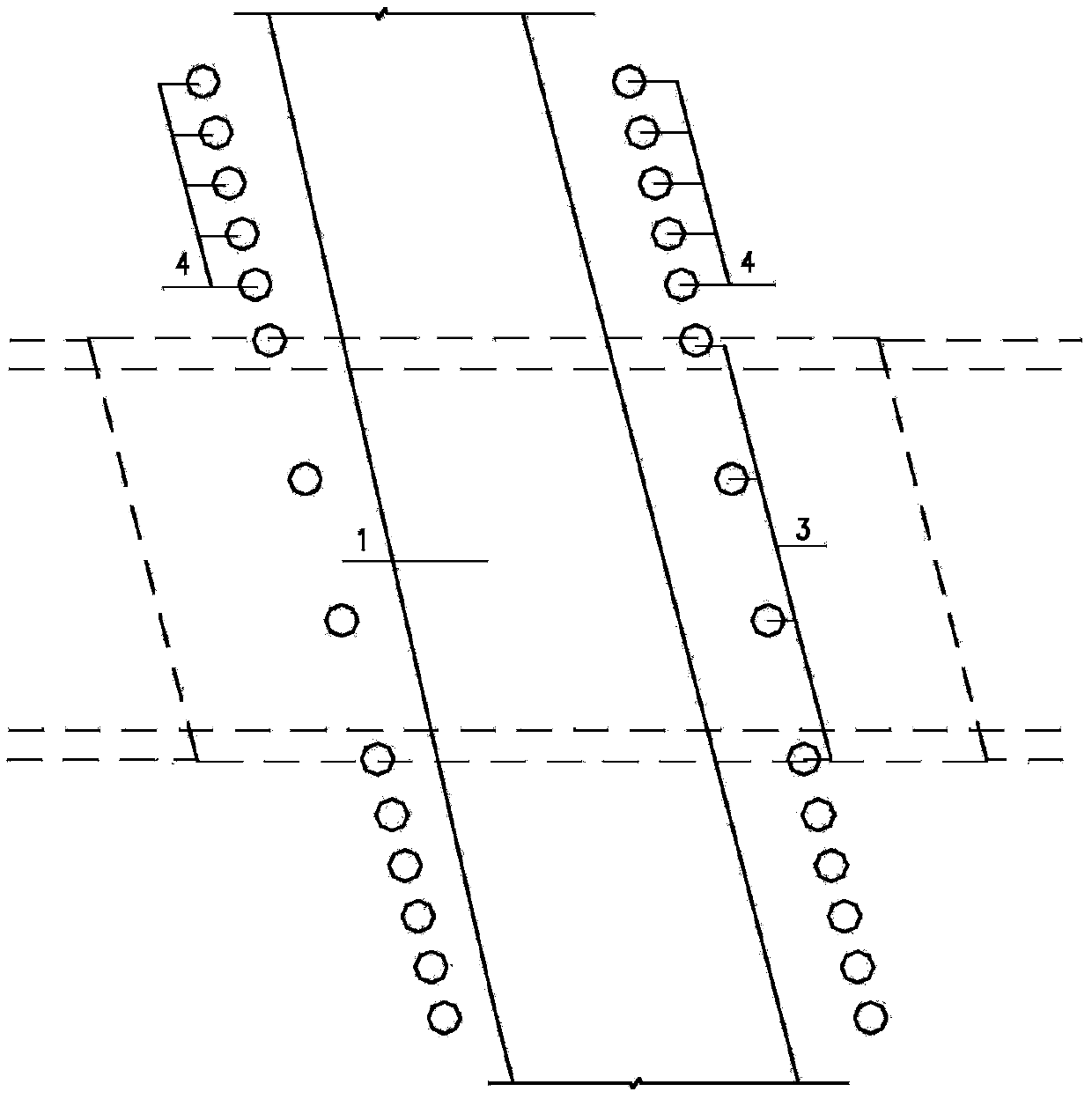

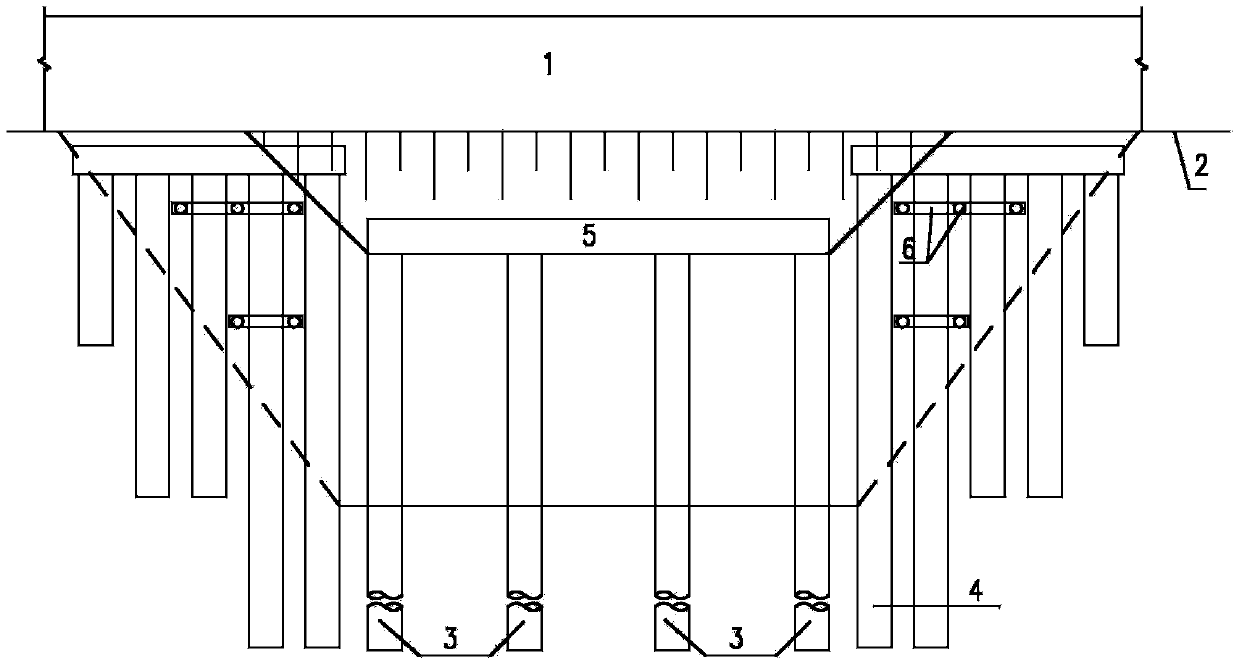

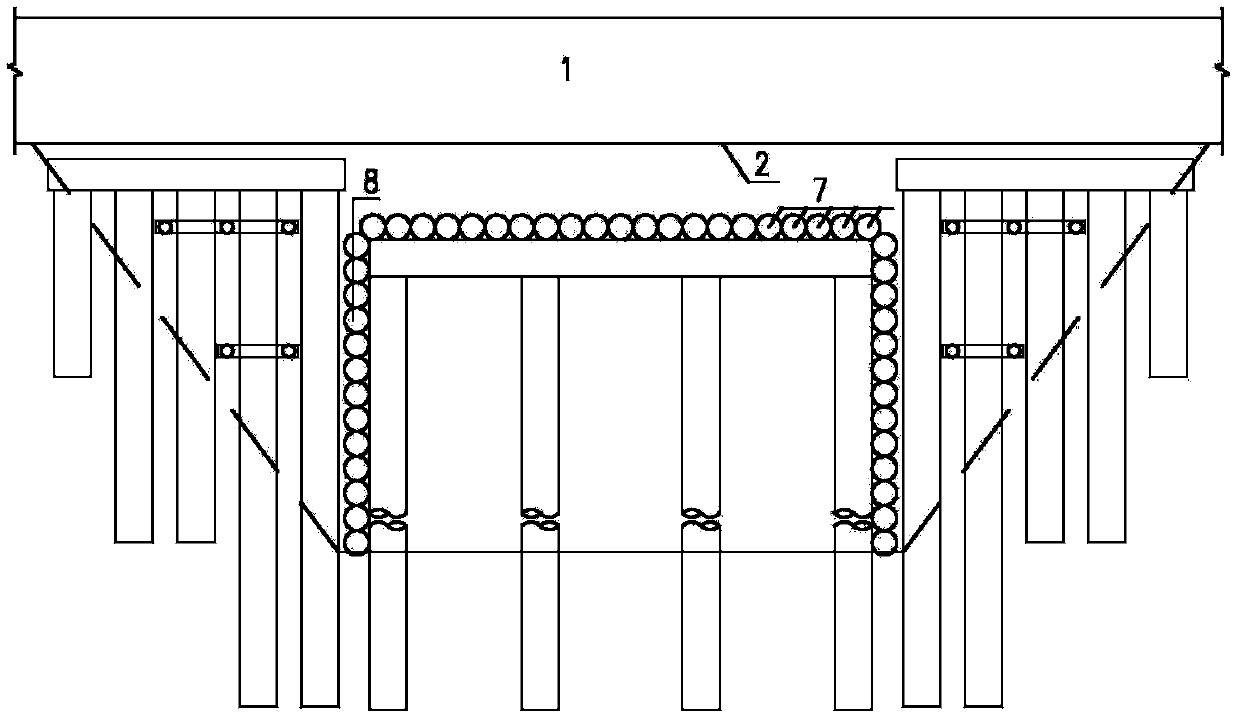

[0025] During the test construction of the technical solution of the present invention, a certain high-speed railway tunnel was selected to pass under the national key protected cultural relics earthy Great Wall ruins project, and the project was successfully applied. The specific procedures are as follows Figure 1~8 shown. A large-diameter long pipe-curtain construction method of the present invention is used to pass through a structure under a shallow-buried long-span tunnel. The tunnel consists of a reinforced concrete roof + side wall to form a door-shaped structure, and a bottom plate separated from the side wall is arranged below. In order to control the settlement of the ground surface, especially the upper Gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com