Sawtoothed angle regulation mechanism for two-dimensional spray pipe

A binary nozzle and angle adjustment technology, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of non-adjustable sawtooth angle and the influence of nozzle stealth performance, etc., and achieve less moving parts, simple structure, and stealth performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

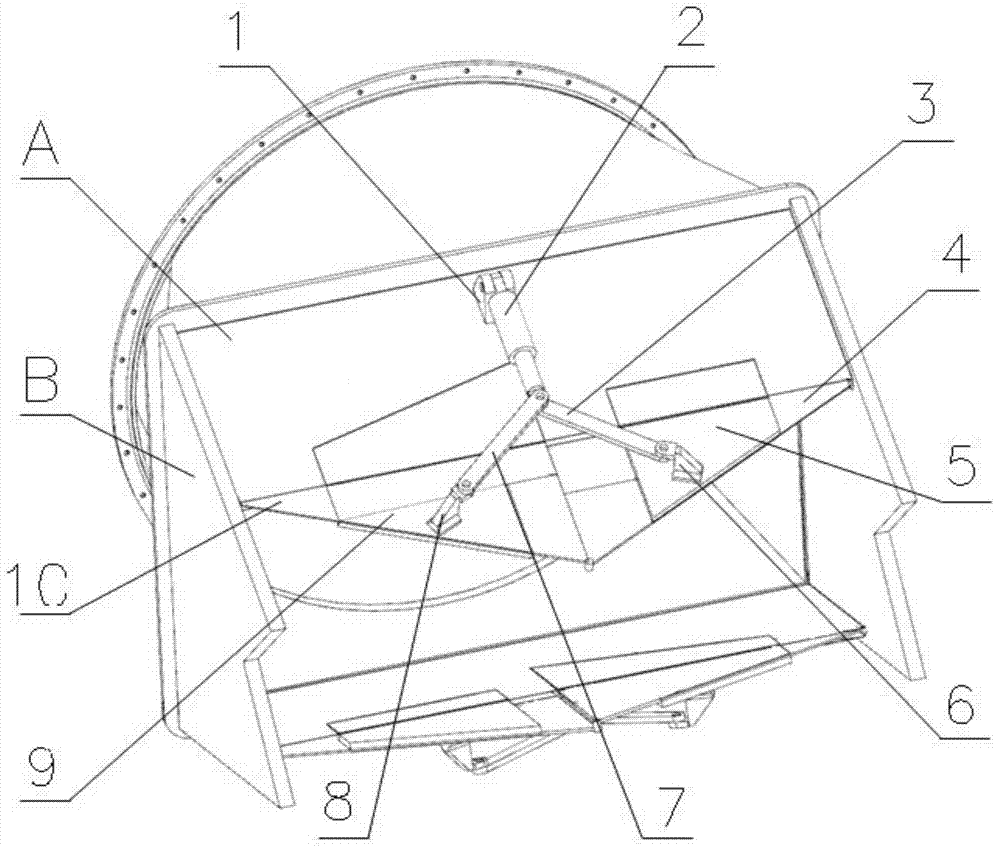

[0017] The present invention provides a binary nozzle sawtooth angle adjustment mechanism, which is characterized in that it includes a mounting base 1, an actuator 2, a pull rod 3, a right sealing plate 4, a right shielding plate 5, a mounting base 6, a pull rod 7, Mounting seat 8, left shielding plate 9 and left sealing plate 10, specifically:

[0018] The mounting base 1 is fixed on the convergence adjustment plate A of the binary nozzle; the side sealing baffle B is fixed on the left and right mounting sides of the round and rotating square cylinder; one end of the actuator 2 is connected with the mounting base 1, and the other end is connected with the rotating pair The tie rod 3 and the tie rod 7 are connected at the hinge; one end of the tie rod 3 and the tie rod 7 is hinged through a rotating pair, and the other end is respectively hinged with the mounting seat 6 and the mounting seat 8 through a rotating pair, and the rotating pair is kept vertical to the convergence a...

Embodiment 2

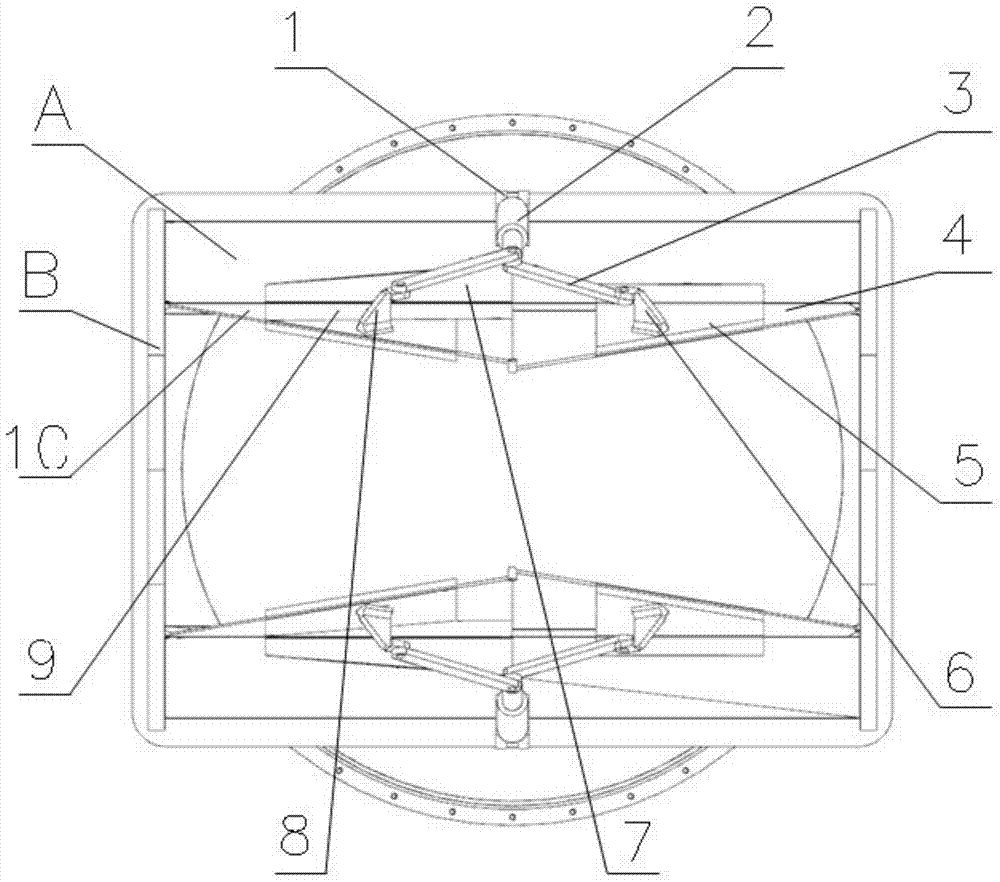

[0022] The present invention provides a binary nozzle sawtooth angle adjustment mechanism, which is characterized in that it includes a mounting base 1, an actuator 2, a pull rod 3, a right sealing plate 4, a right shielding plate 5, a mounting base 6, a pull rod 7, Mounting seat 8, left shielding plate 9 and left sealing plate 10, specifically:

[0023] The mounting base 1 is fixed on the convergence adjustment plate A of the binary nozzle; the side sealing baffle B is fixed on the left and right mounting sides of the round and rotating square cylinder; one end of the actuator 2 is connected with the mounting base 1, and the other end is connected with the rotating pair The tie rod 3 and the tie rod 7 are connected at the hinge; one end of the tie rod 3 and the tie rod 7 is hinged through a rotating pair, and the other end is respectively hinged with the mounting seat 6 and the mounting seat 8 through a rotating pair, and the rotating pair is kept vertical to the convergence a...

Embodiment 3

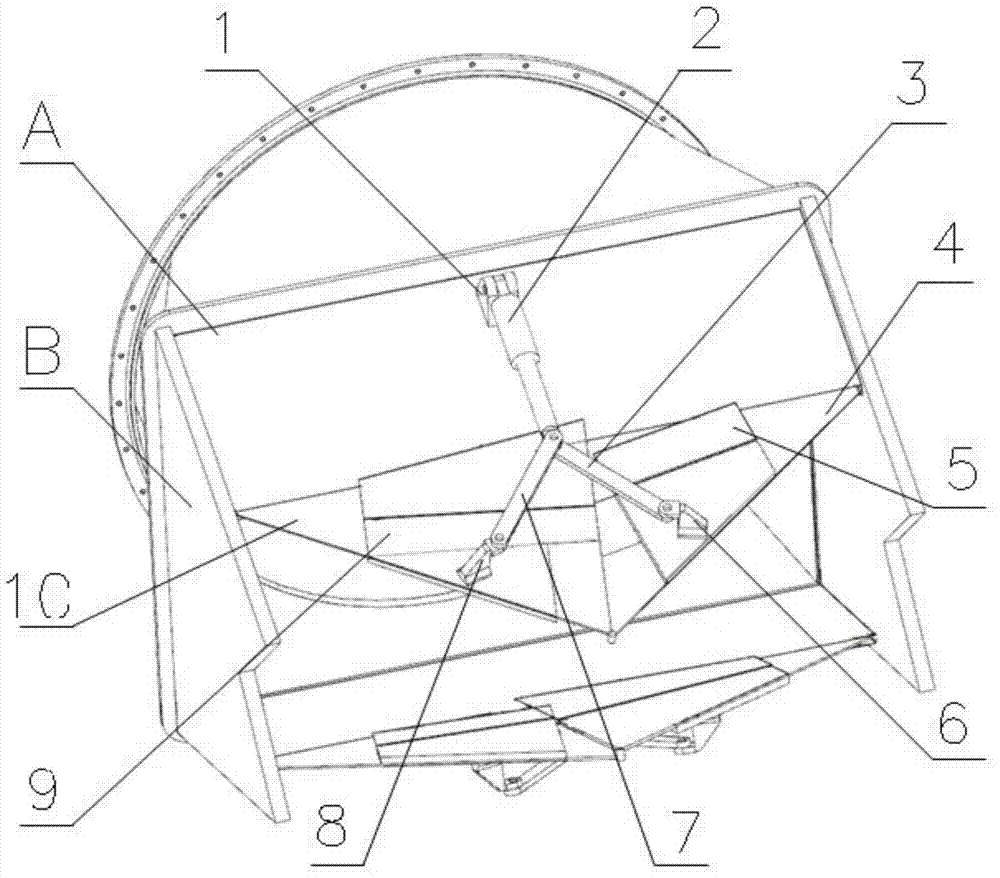

[0027] The present invention provides a binary nozzle sawtooth angle adjustment mechanism, which is characterized in that it includes a mounting base 1, an actuator 2, a pull rod 3, a right sealing plate 4, a right shielding plate 5, a mounting base 6, a pull rod 7, Mounting seat 8, left shielding plate 9 and left sealing plate 10, specifically:

[0028] The mounting base 1 is fixed on the convergence adjustment plate A of the binary nozzle; the side sealing baffle B is fixed on the left and right mounting sides of the round and rotating square cylinder; one end of the actuator 2 is connected with the mounting base 1, and the other end is connected with the rotating pair The tie rod 3 and the tie rod 7 are connected at the hinge; one end of the tie rod 3 and the tie rod 7 is hinged through a rotating pair, and the other end is respectively hinged with the mounting seat 6 and the mounting seat 8 through a rotating pair, and the rotating pair is kept vertical to the convergence a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com