Magnetic-inductive volumetric flow meter

A technology of flow measurement and electromagnetic induction, which is applied in the field of electromagnetic induction flow measuring instruments, can solve the problems of inability to distinguish reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

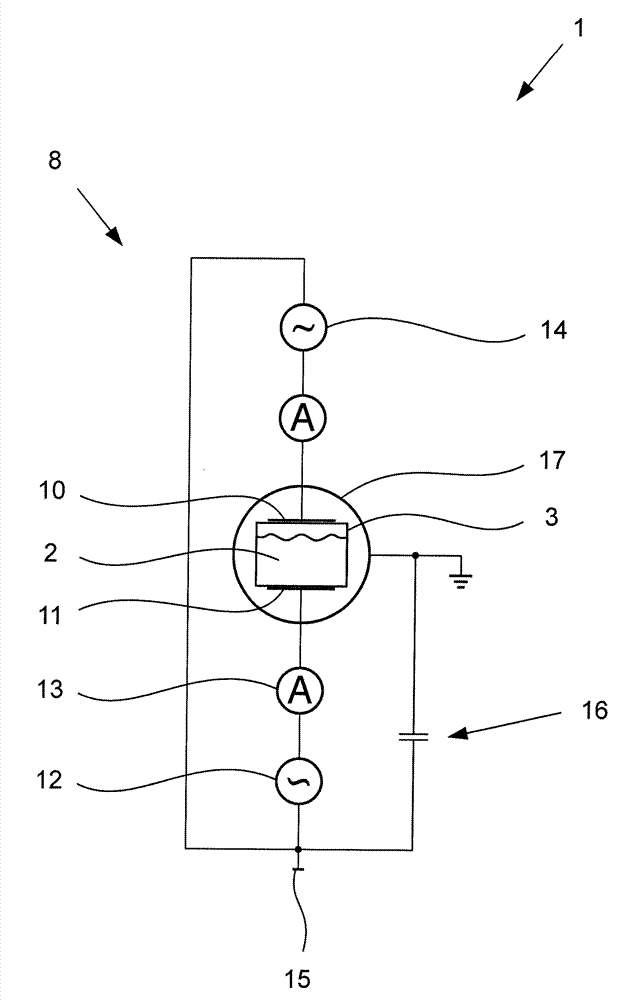

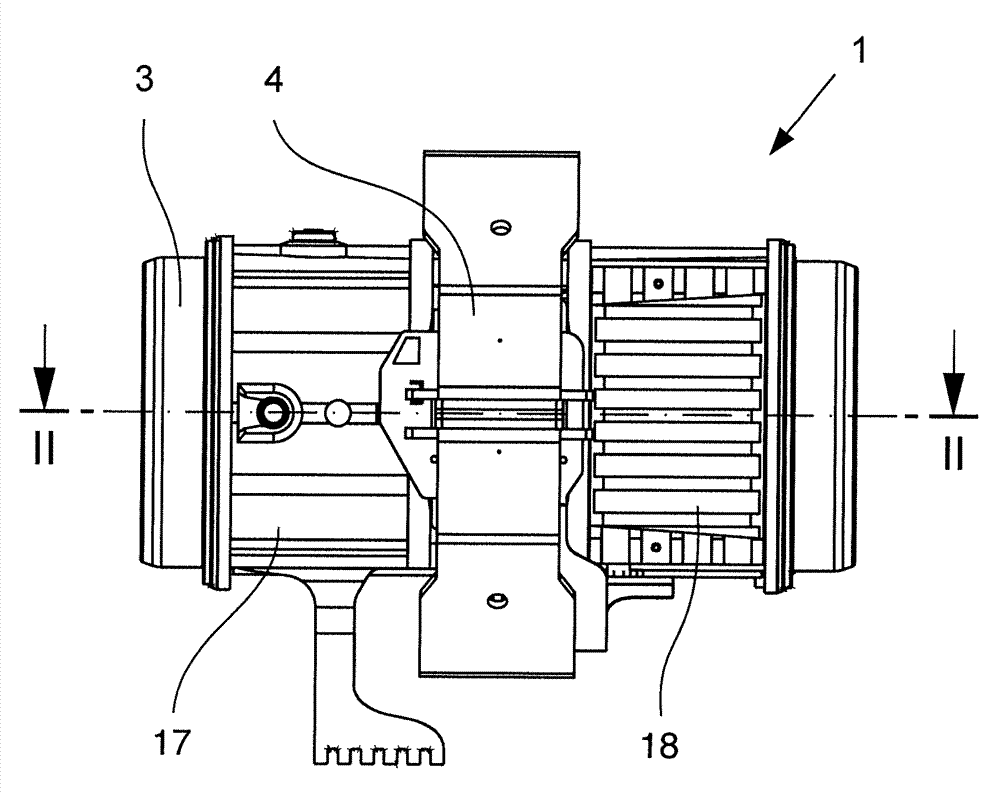

[0037] Figure 1 to Figure 3 A preferred exemplary embodiment of an electromagnetically inductive flowmeter 1 according to the invention for measuring the flow rate of a conductive medium 2 flowing in a measuring tube 3 is shown. For measuring the flow of the medium 2 , a magnetic field generator is provided which has two coils 4 which are externally mounted on the measuring tube 3 on opposite sides and which are supplied by a current generator (not shown here). A magnetic field generating device or coil 4 generates a magnetic field through which the measuring tube 3 runs approximately perpendicular to its longitudinal axis 5 . Furthermore, two measuring electrodes 6 , 7 are provided, which are galvanically connected to the medium 2 and which intercept the measuring voltage induced in the flowing medium 2 . In addition to the galvanic coupling of the measuring electrodes 6 , 7 provided here to the medium 2 , capacitive coupling is also possible in principle.

[0038] In addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com