A linear led drive circuit based on alternating current power supply

A technology of LED driving and alternating current, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems of affecting eyesight health, lamp light and shade changes, LED average luminous intensity changes, etc., to improve electric energy conversion efficiency and constant average power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

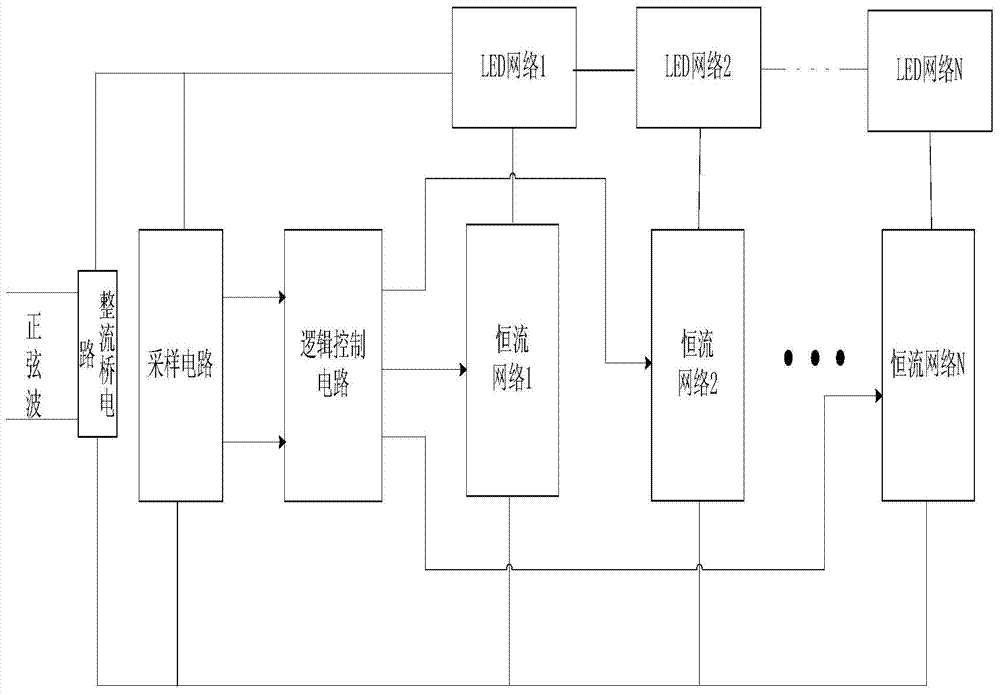

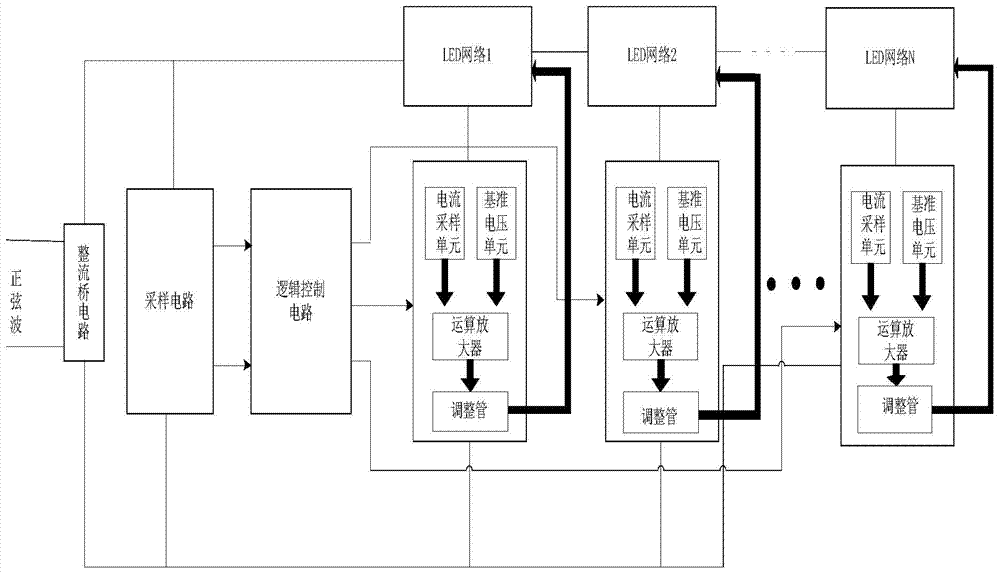

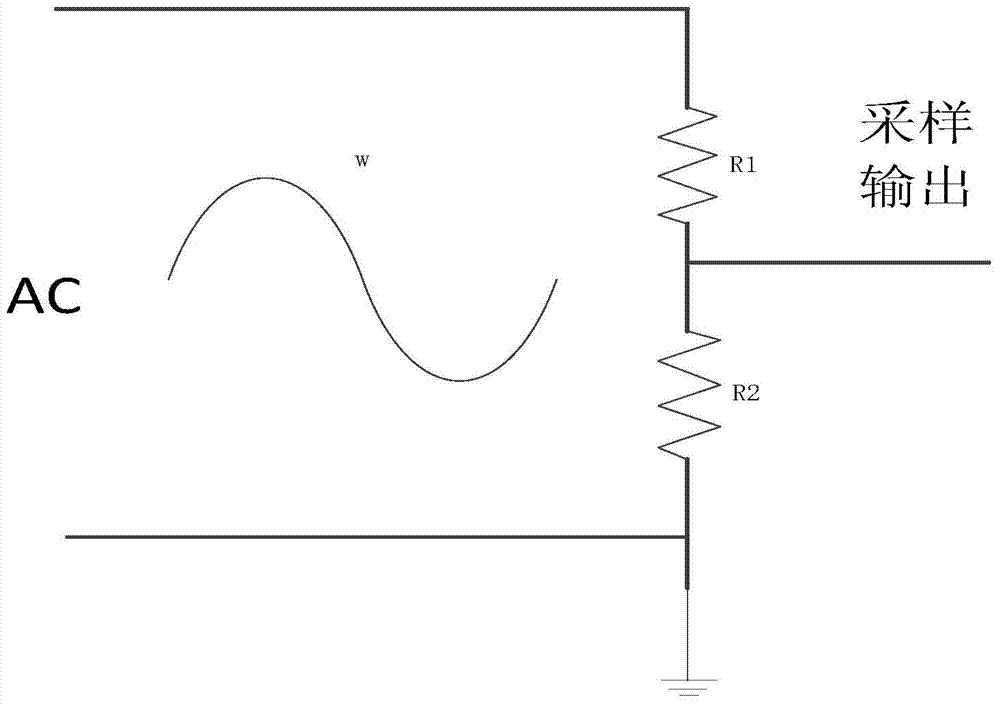

Method used

Image

Examples

Embodiment 1

[0035] Such as Figure 7 As shown, the LED module in this example includes 4 LED branches, and each LED branch includes 3 LED lamp beads. All comparators use operational amplifiers. The specific working principle is:

[0036] The AC sine wave AC is rectified by the rectifier bridge to become DC. When the voltage is zero, the four LED modules have no current, the current flowing through the sampling resistor Rs is zero, the voltage on the sampling resistor is zero, and the voltage fed back to the negative input terminals of the four operational amplifiers is zero. In the voltage divider module set by the sampling circuit, the sampling voltage is 0, and the outputs of M1, M2, M3, and M4 are all low level. M1, M2, M3, and M4 are respectively connected to the enabling terminals of the operational amplifiers from branch one to branch four, forcing the output of the operational amplifier to be low level, and the four MOS transistors M1M2...M4 are in the cut-off state. Duration is ...

Embodiment 2

[0061] Such as Figure 8 As shown, the basic structure and principle of this example are the same as those of Example 1. The difference is that in this example, the reference voltage input by the non-inverting terminal of the operational amplifier is set to be equal, and the clamping effect of the operational amplifier is used to ensure the constant current of the LED lamp bead.

[0062] Such as Figure 9 As shown, it is a low-offset high-gain operational amplifier with an enable terminal in the present invention, which can be used as a comparator.

[0063] Such as Figure 10 Shown is the waveform diagram of the rectified waveform and the comparative voltage in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com