Efficient dust absorbing device for unloading work of bulk-grain carrier

A dust collection device and automobile technology, applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of insignificant effect of the auxiliary dust area 12, small influence of dust, and fast and slow grain unloading speed, etc., to achieve Effects of reducing dust overflow, reducing dust content, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

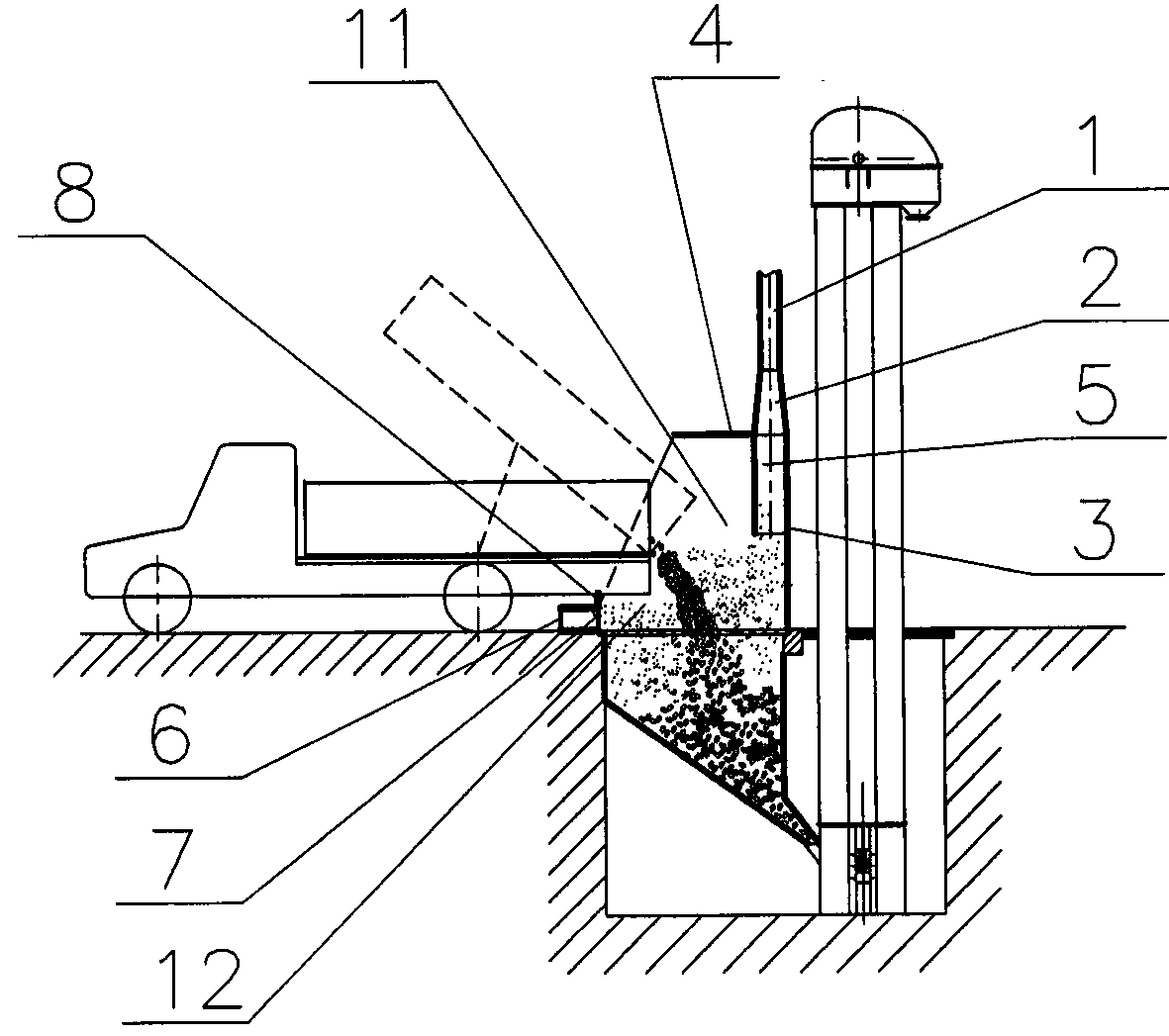

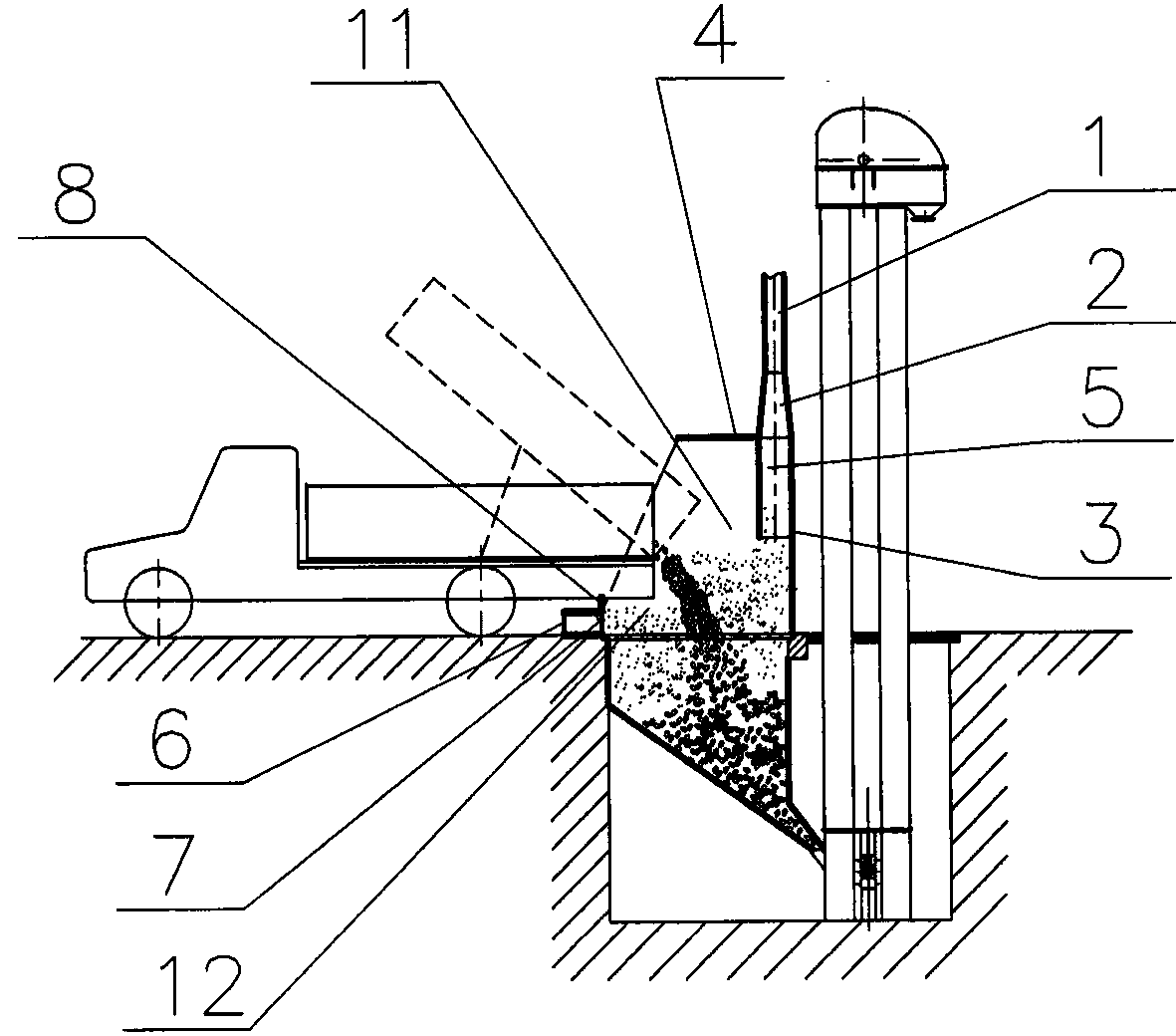

[0016] Such as figure 2 As shown, the present invention adopts the following technical solutions: a high-efficiency bulk grain vehicle unloading dust suction device includes a suction pipe 1, a connecting section 2, a rear windshield 3, a left windshield, and a right windshield. It also includes a top plate 4, an inner wind deflector 5, and a horizontal suction pipe 6; the inner wind deflector 5 is arranged under the top plate 4, and forms a vertical air suction channel with the left and right windshields and the rear windshield 3. The vertical suction channel communicates with the suction pipe 1 through the connecting section 2 .

[0017] The height of the inner wind deflector 5 is half of the height of the rear wind deflector, or the height of the inner wind deflector 5 is greater than half of the height of the rear wind deflector 3 .

[0018] Desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com