Building solid waste treatment device

A solid waste and treatment device technology, applied in grain processing, cleaning hollow items, using liquid separators, etc. Avoid dust rising, reduce dust overflow, good effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

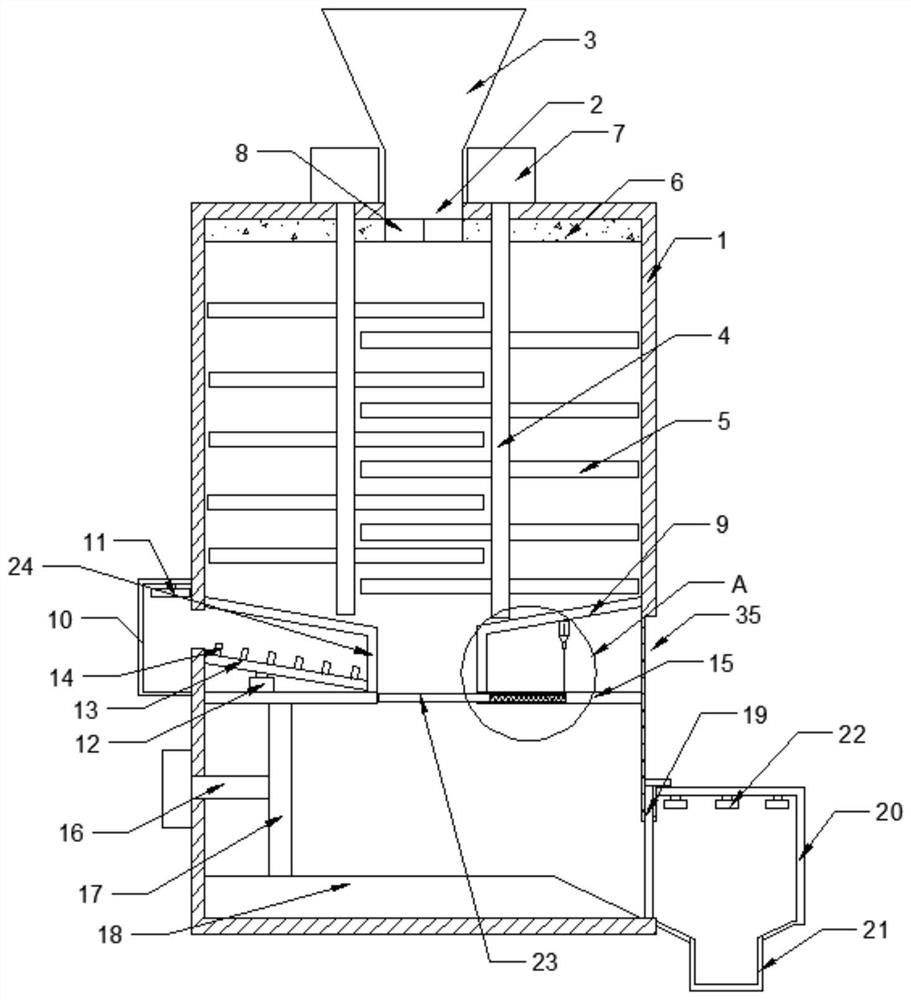

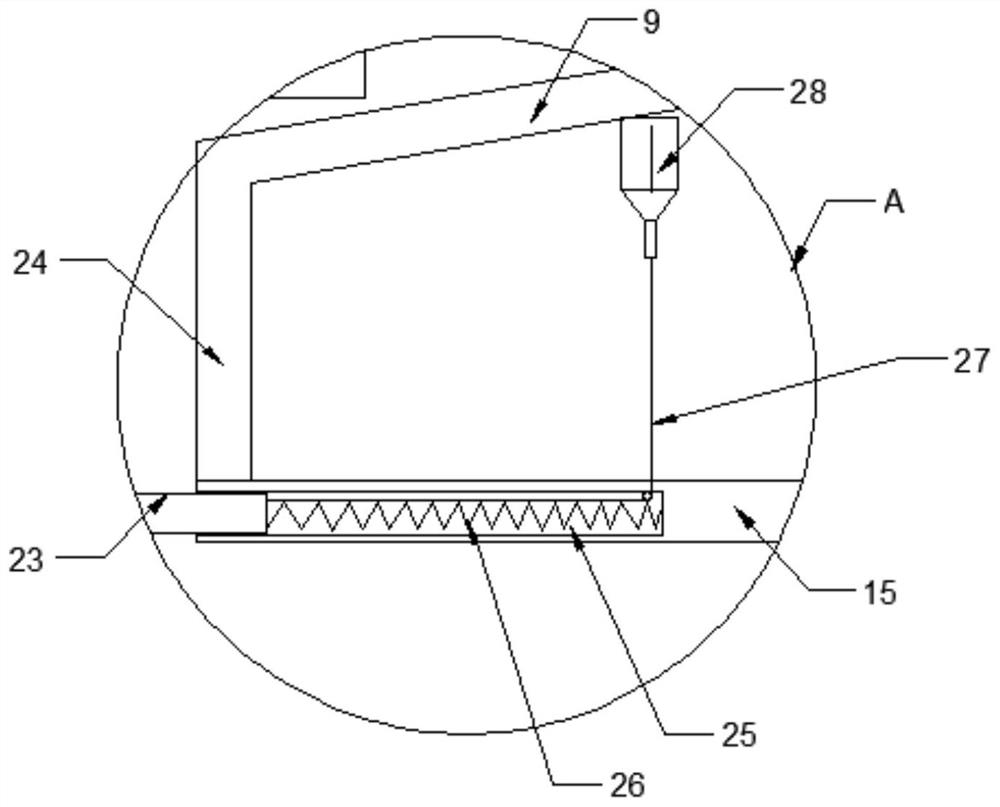

[0030] Such as Figure 1-6 As shown, the present invention provides a construction solid waste treatment device, comprising:

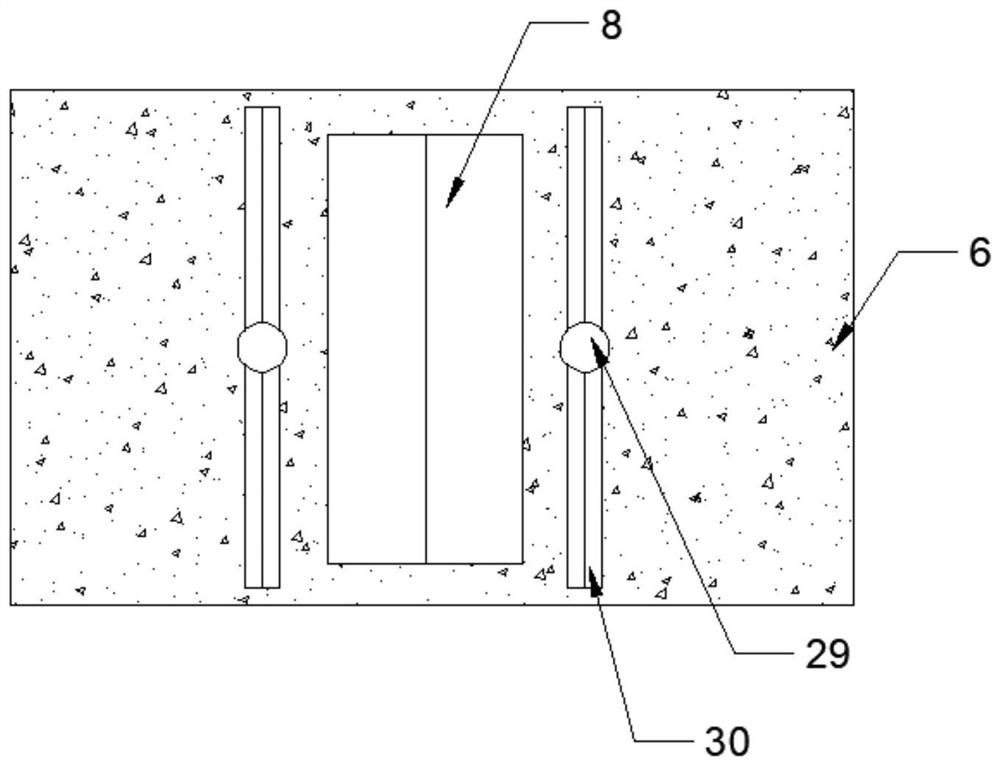

[0031] Tank body 1, its top is provided with feed inlet 2, and bottom is provided with discharge outlet, and described tank body 1 is provided with two rotating shafts 4, and each rotating shaft 4 is provided with a plurality of stirring rods 5 and a plurality of stirring rods 5 are positioned at On the same vertical plane, the stirring rods 5 on the two rotating shafts 4 are arranged crosswise (the stirring rods 5 on the two rotating shafts 4 are crossed when the rotating shaft 4 rotates);

[0032] An anti-overflow mechanism, which includes an anti-overflow plate 6 sliding up and down in the tank body 1 (the side wall of the anti-overflow plate 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com