Coordinated assembly method of a separation device with three butt joints

A separation device and assembly method technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems that the separation device cannot be used, and achieve the effect of meeting the assembly strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

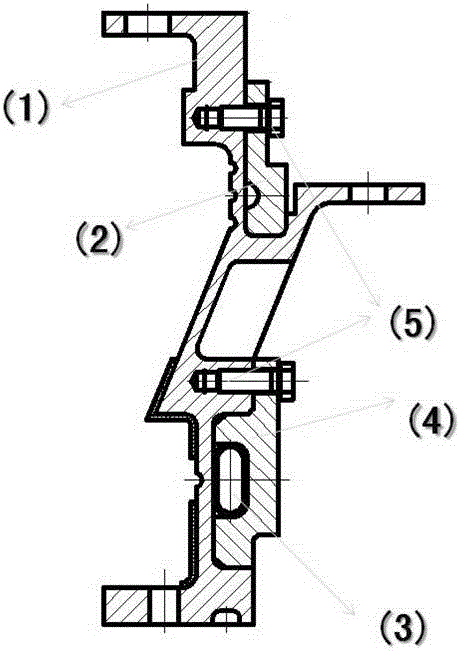

Image

Examples

Embodiment Construction

[0042] A method for coordinating the assembly of a separation device with three butt joints, comprising the following steps:

[0043] Step 1: Measure the height of the cutting cable protective cover, position the cutting cable protective cover assembly on the frame, select 48 points to measure the height after the assembly is installed, and adjust to a height fluctuation value less than 0.2mm to ensure that there is no gap after the assembly is installed;

[0044] The cutting cable protective cover assembly is composed of a protective cover and a detonating joint. Before assembly, the two parts are connected with pins and bolts to form a complete circle, making it a cutting cable protective cover assembly. Measure the height h of the protective cover and the depth H of the groove on the frame, and record the dimensions. Position the component according to the quadrant, try to fit it into the groove of the frame, and measure the distance L between the upper end of the protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com