Sewing machine chuck

A sewing machine and chuck technology, which is applied to workpiece clamping devices, manufacturing tools, etc., to achieve the effects of convenient and accurate adjustment and positioning, wide application range and large controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

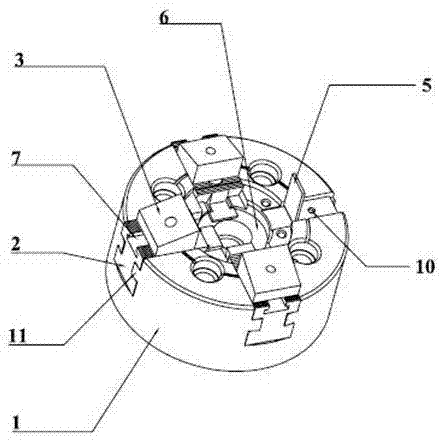

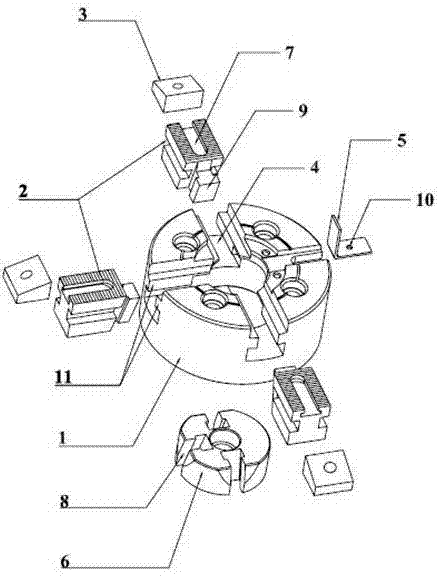

[0013] Such as Figure 1-2 As shown, the chuck of the sewing machine includes a chuck body 1, three sliding blocks 2 and three claws 3; the chuck body 1 is provided with three sliding grooves 4 radially, and the sliding block 2 is arranged on the sliding The chuck 3 is arranged on the slider 2, which also includes a positioning claw 5 arranged on the chuck body 1, and is arranged in the chuck body 1, and can slide along the sliding groove 4. Pull the sliding block 2 synchronously to retract toward the center of the chuck body 1 or synchronously away from the center of the chuck body 1 for the retractable disk 6; the chuck body 1 is also radially provided with a guide groove 7, and the positioning claw 5 is provided in the In the guide groove 7 and movable along the guide groove 7, the base of the positioning claw 5 is provided with a fixing member that can fix it at a certain position in the guide groove 7; there are three each of the sliding groove, the sliding block and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com