Electric screwdriver

An electric screwdriver and battery technology, applied in screwdrivers, power tools, portable mobile devices, etc., can solve the problems of aging of contact pieces, poor contact, interruption of electric screwdrivers, etc., to extend the service life, not easy to power off, reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

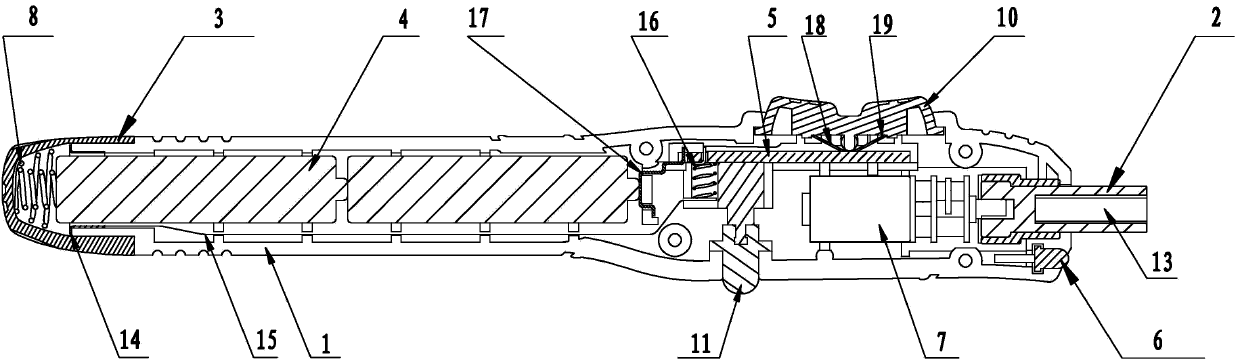

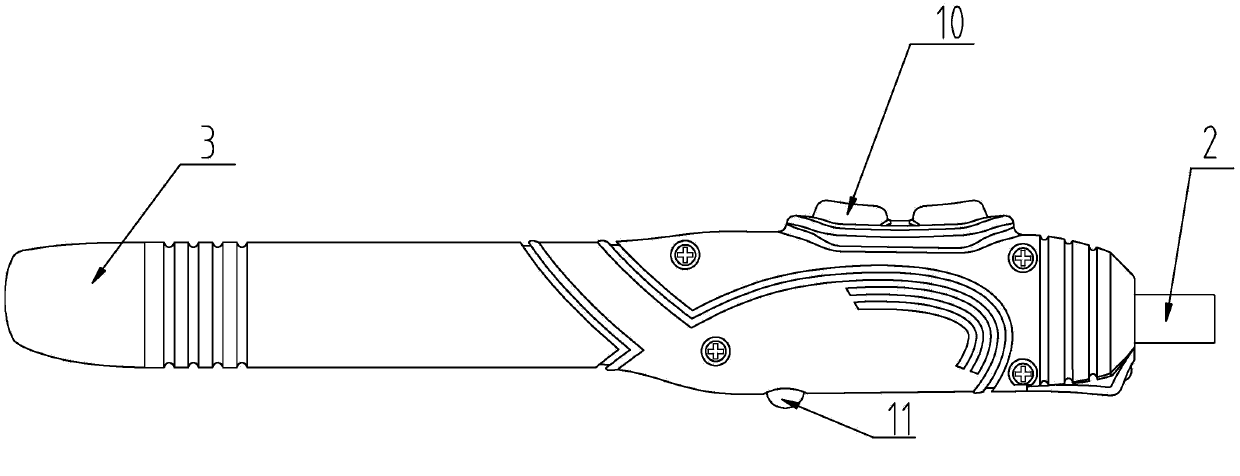

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] As shown in the figure, the present invention provides an electric screwdriver, which includes a hollow cylindrical shell 1, a motor 7, a gear output shaft 2 connected to the motor 7, a tail cover 3, a battery 4 and a negative contact piece 15, the The tail cover 3 is arranged on the end of the casing 1 away from the gear output shaft 2, the maximum diameter of the casing 1 is 24 millimeters to 35 millimeters, and it also includes a special-shaped spring 8 connected to the battery 4 and arranged in the tail cover 3 1. One end is connected to the special-shaped spring 8, and the other end is connected to the battery coil 14 connected to the negative electrode contact piece 15. The described tail cover 3 is engaged with the shell 1. The described special-shaped spring 8 refers to that the outer spring coil and the inner spring coil are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com