Multifunctional clamping jaw mechanism of mechanical arm

A multi-functional manipulator, manipulator technology, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of low work efficiency, cumbersome and complicated work flow, etc., and achieve the effect of reducing the use of manpower, high speed, and saving work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

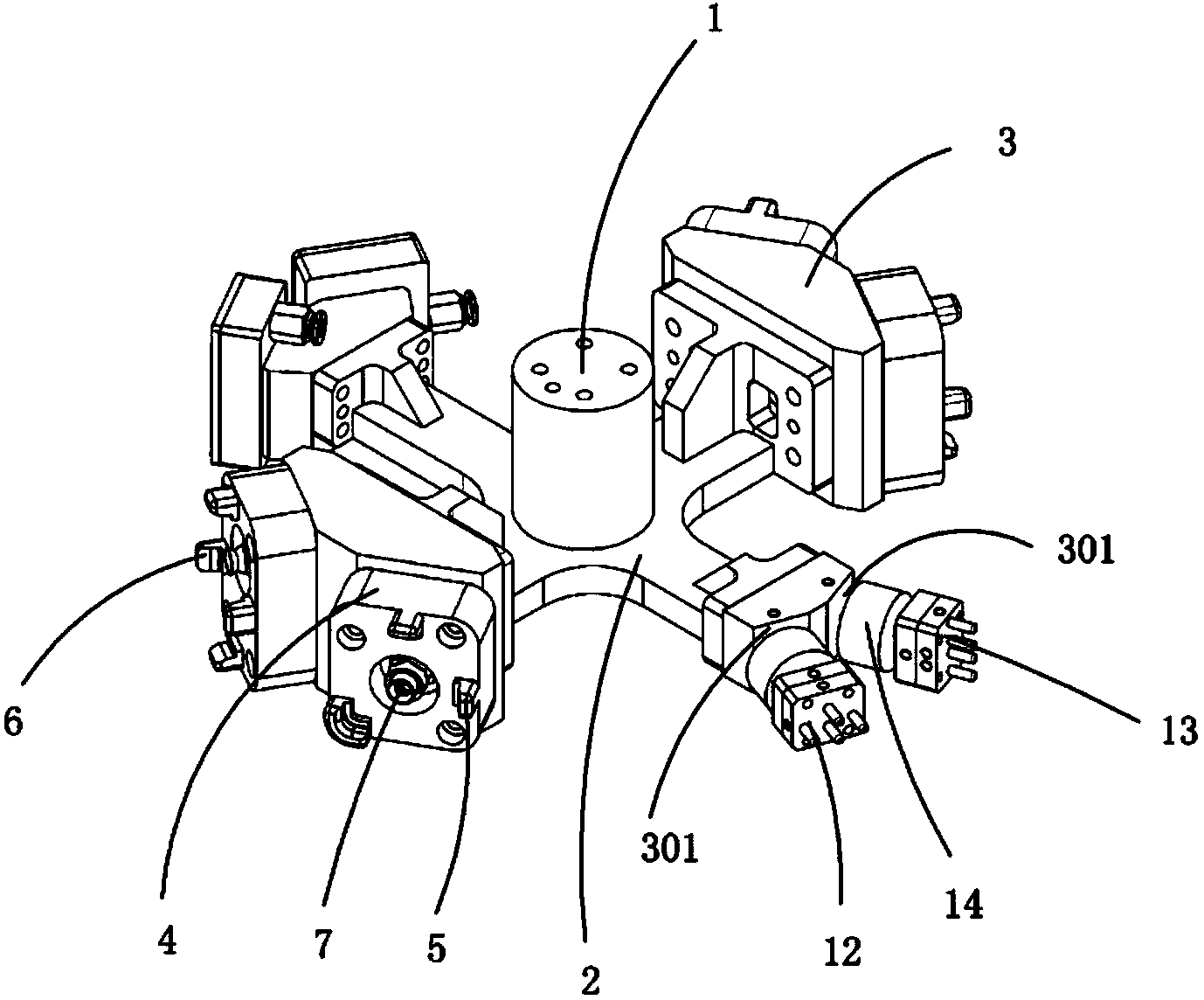

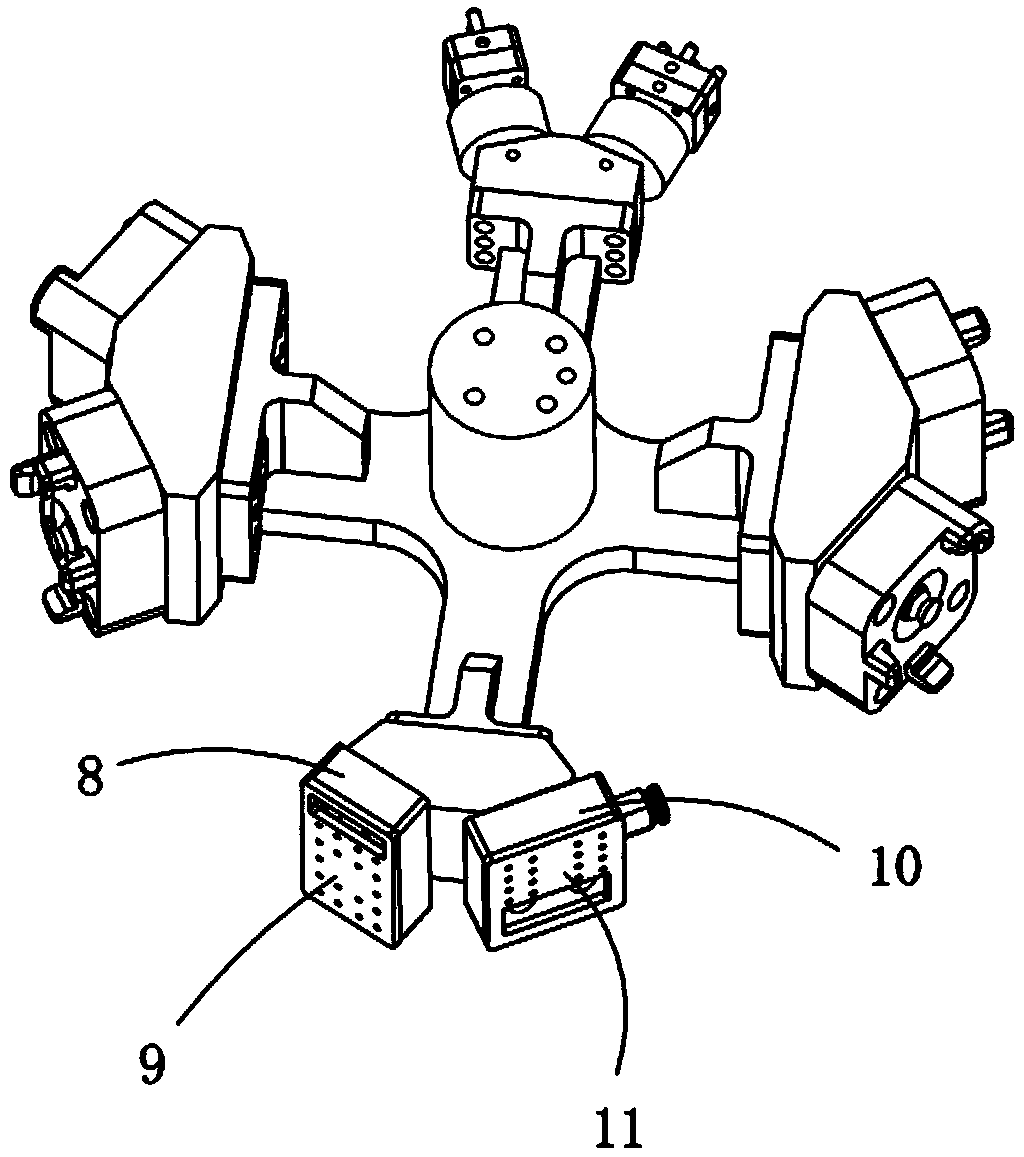

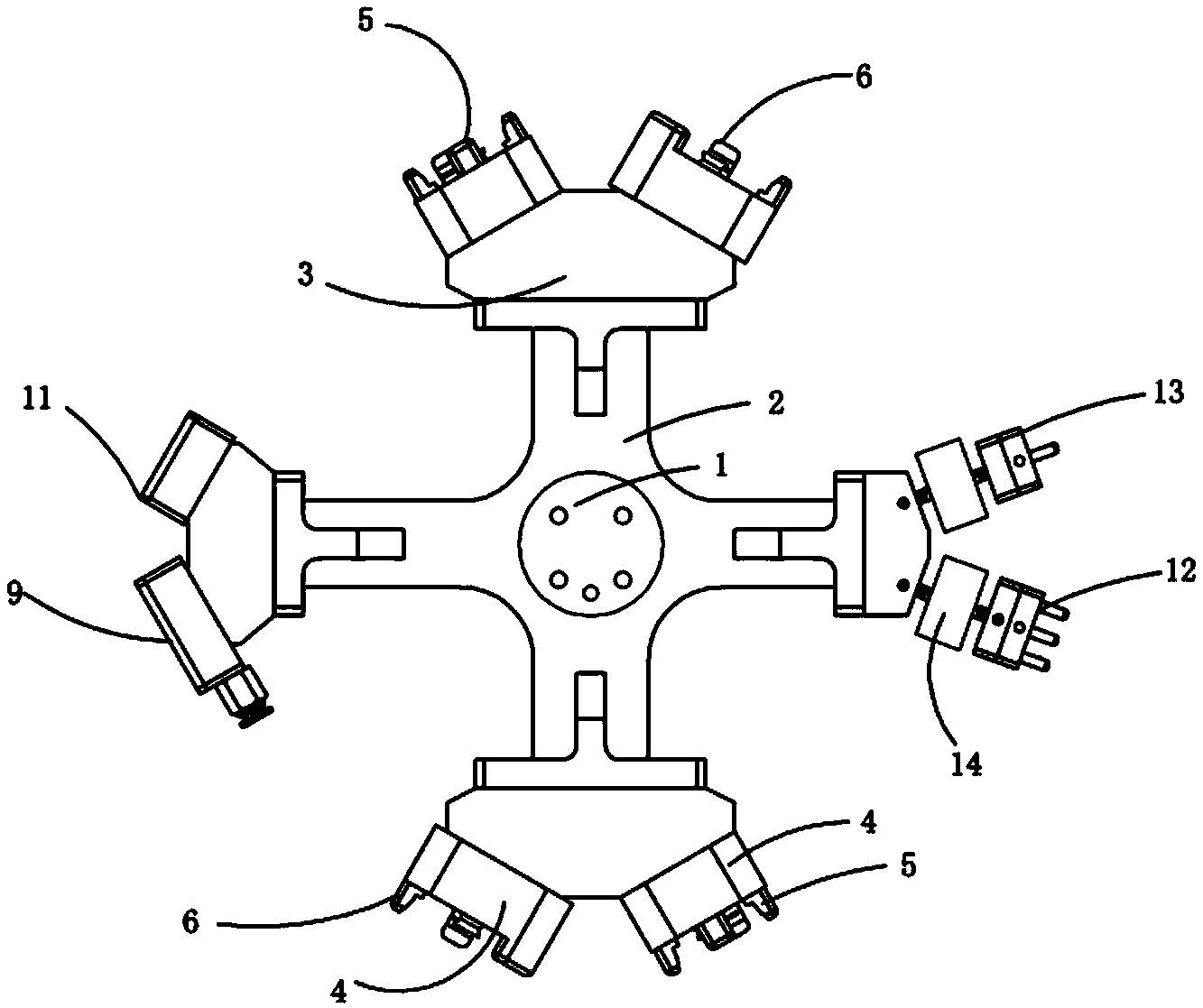

[0019] Examples, see attached Figure 1~3 , a multifunctional manipulator jaw mechanism, which includes a manipulator connecting column 1, a jaw body flange 2 and a switchable jaw part, the jaw main body flange is installed on the manipulator connecting column; the jaw body method Four jaw connectors 3 are symmetrically arranged on the blue, and each jaw connector is provided with two inclined surfaces 301; the switchable jaw parts include four kinds of jaw parts, and the four kinds of jaw parts are respectively Correspondingly installed on the inclined surfaces of the four jaw connectors; the four kinds of jaw parts include two groups of manipulator jaw parts, film suction nozzle parts and button finger parts.

[0020] The upper part of the connecting column of the manipulator is connected to a six-axis robot or a manipulator with more than three axes. With the cooperation of the robot or a manipulator with more than three axes, it can quickly switch to the corresponding jaw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com