A wooden lathe fixture

A technology of wood lathes and fixtures, which is applied in woodworking lathes, wood processing equipment, manufacturing tools, etc. It can solve problems such as difficult processing, and achieve the effect of convenient and simple application, safe and reliable processing environment, and enhanced flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

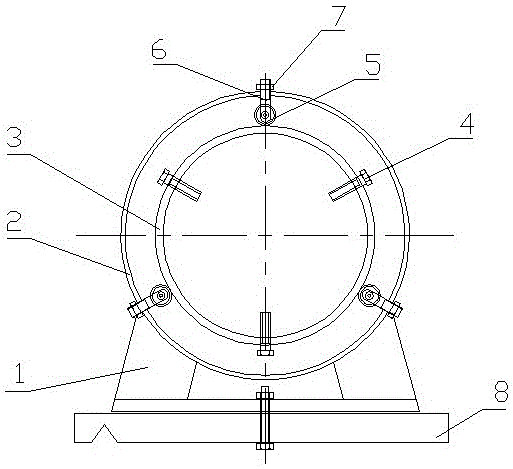

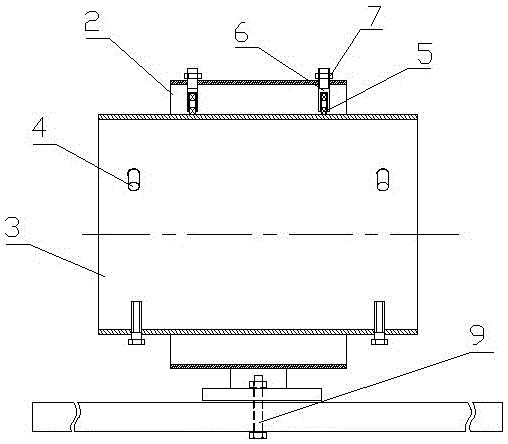

[0013] A wooden lathe fixture, comprising a machine tool slider 8, a base 1, an outer ring 2, an inner ring 3, an outer ring 2 and an inner ring 3 are arranged on the base 1, a bolt 6 is arranged on the outer ring 2, and one end of the bolt 6 A bearing 5 is provided, a nut 7 is provided at the other end, and a screw 4 is provided on the inner ring 3. Three sets of bearings 5 form a group and are arranged at 120 degrees along the circumference. Near both ends, there are two groups of screws 4 on the inner ring 3, each set of three sets is arranged along the circumference at 120 degrees, respectively arranged at the near ends of the inner ring 3, the bearing 5 and the outer side of the inner ring 3 In contact with each other, the base 1 is set on the machine tool slider 8 and connected by the fixing screw 9. The base 1 can be disassembled or the steering can be adjusted by 180 degrees.

[0014] Install the base 1 on the machine tool slider 8, connect and fix it through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com