A method for starting a BLDC motor without a position sensor

A sensor and motor-driven technology, which is applied in the control of generators, motor generators, electronic commutation motors, etc., can solve the problems of inrush current power component noise, large inrush current, and affecting the working life of motors, and achieve operability Strong, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

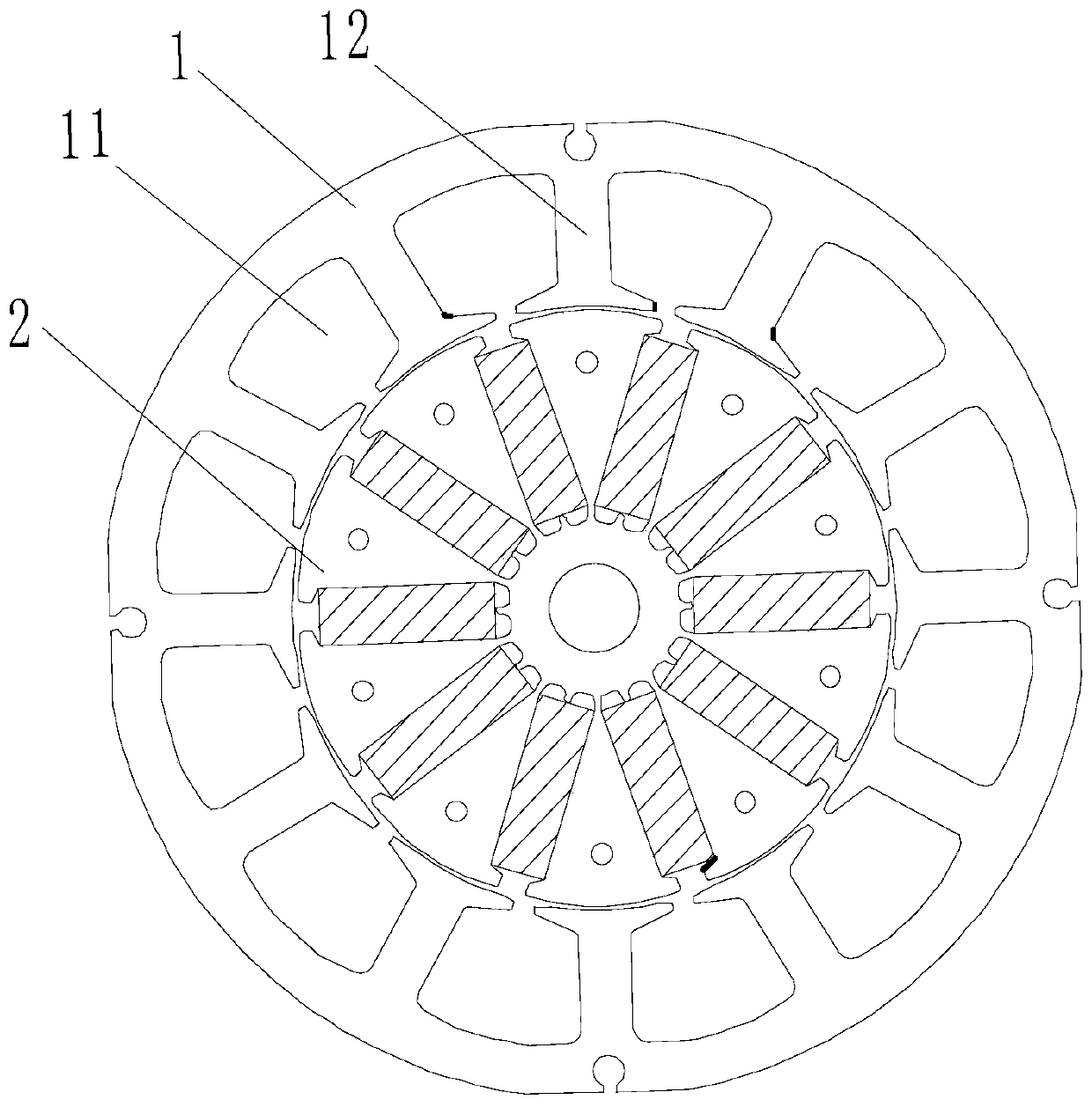

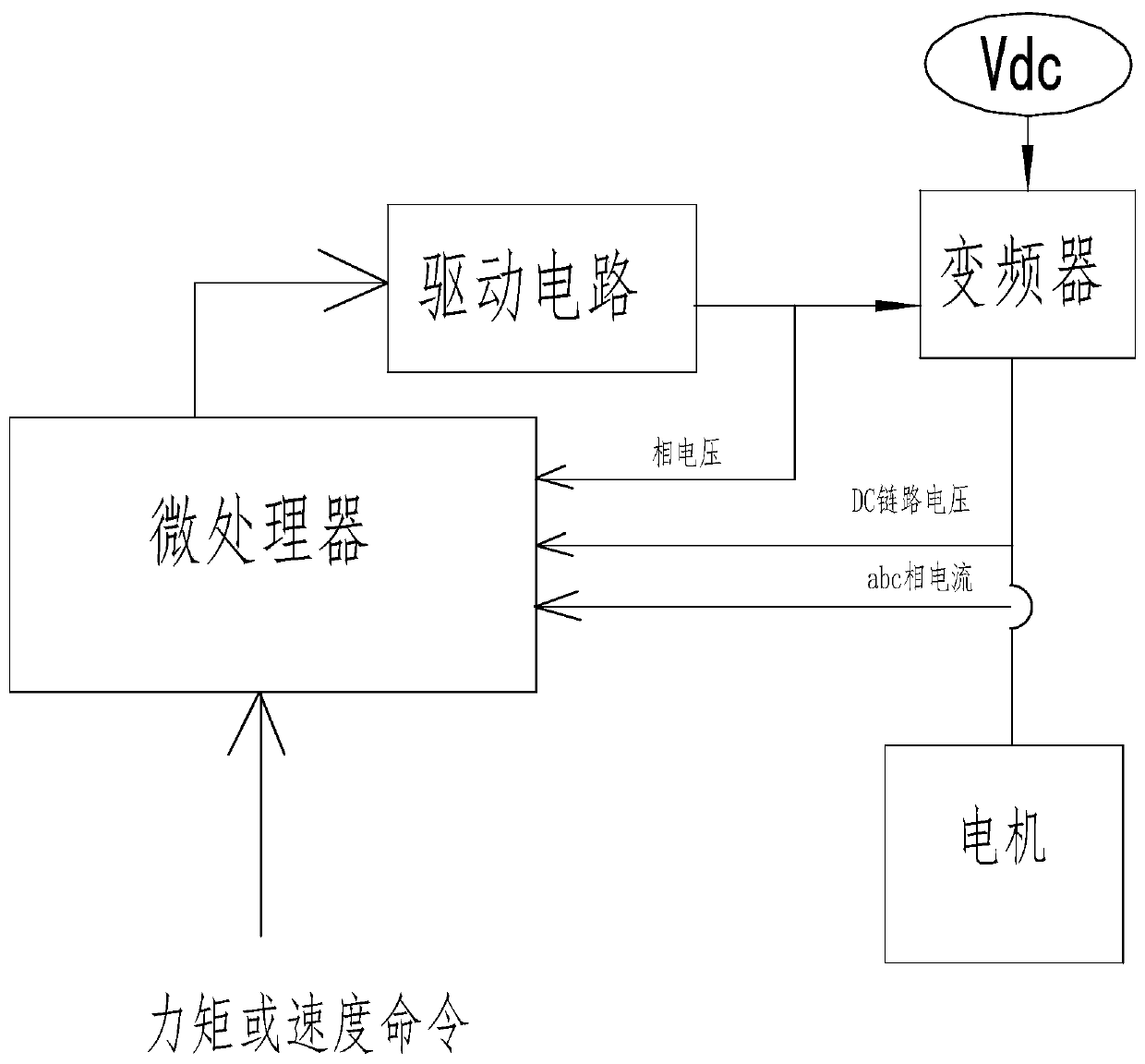

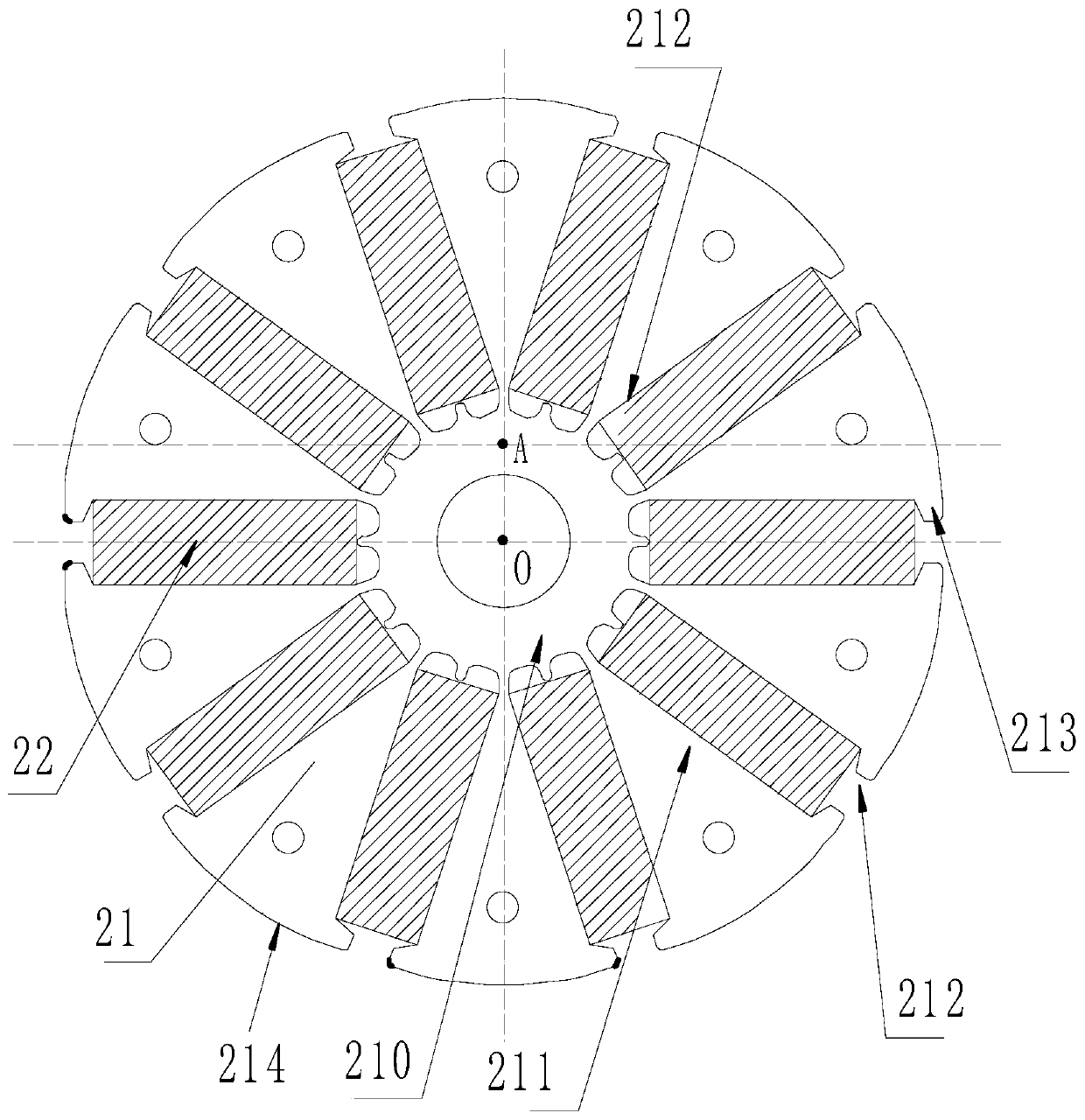

[0044] Such as figure 1 , figure 2 , image 3 As shown, the BLDC motor without a position sensor includes a stator assembly, a rotor assembly 2 and a motor controller. The stator assembly includes a stator core 1 and a coil winding. The stator core 1 is provided with teeth 12 and slots 11, and the coil winding is wound on the teeth 12. , the rotor assembly is a salient pole inner rotor, the motor controller adopts the vector control method without position sensor, the motor controller includes a microprocessor, a frequency converter and a detection unit, the detection unit inputs the phase current, DC bus current and phase voltage to the micro The processor and the microprocessor output signals to control the frequency converter, the frequency converter is connected to the winding of the stator assembly, the range of the salient polarity Lq / Ld of the salient pole rotor is 1.3-1.7, and the range of the air gap flux density on the surface of the salient pole rotor From 0.6 Te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com