Upper race lubricating method for rapid thermal processing (RTP) machine station

A ball and top ring technology, used in mechanical equipment, electrical components, bearing components, etc., can solve the problems of scratches on the back of the product, unsatisfactory lubrication effect, uneven rotation of the edgering, etc., to improve the lubrication state and reduce scratches. Risk, the effect of smooth and even rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

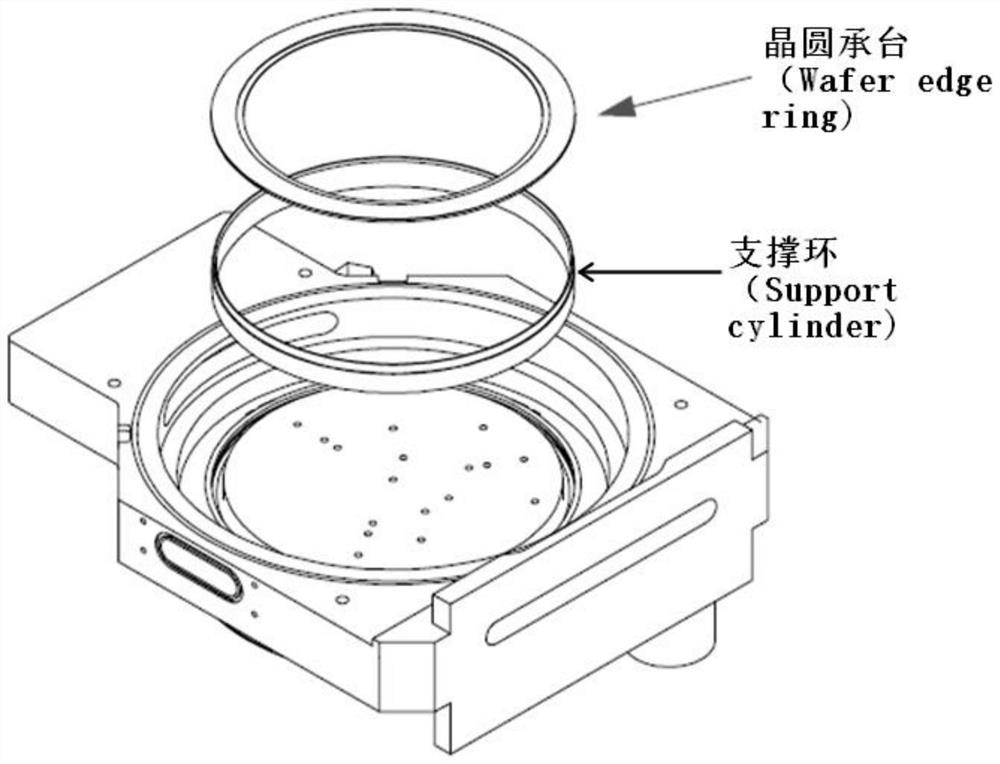

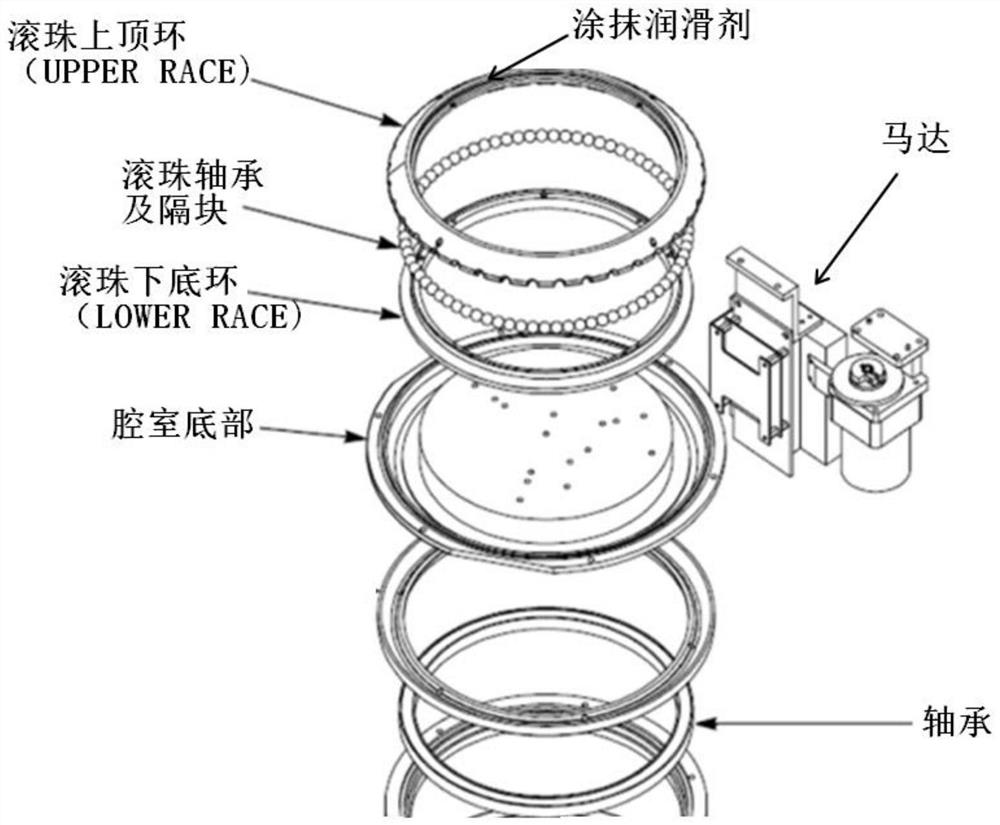

[0017] In the method for lubricating the upper top ring of the RTP machine ball according to the present invention, the wafer support platform of the machine is supported by a supporting structure composed of the upper top ring of the ball, the ball bearing, the spacer, and the lower bottom ring of the ball; figure 1 and figure 2 as shown, figure 1 The middle part is the wafer support, which is a structural part directly in contact with the wafer. The wafer is placed on the wafer support, and the wafer support drives the wafer to rotate. figure 2 The supporting structure shown is located at figure 1 Below the wafer pedestal shown, the wafer pedestal is supported. The ball bearing and the spacer are located between the upper top ring of the ball and the lower bottom ring of the ball. The ball bearing is composed of multiple balls and spacers. The balls can roll freely and flexibly to reduce the coefficient of friction. Multiple spacers are located between the balls to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com