Pay-off rack of rigid conductor wire coil winding machine

A technology of a disc machine and a pay-off rack, applied in the field of pay-off racks, to achieve the effects of simple structure, precise positioning, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

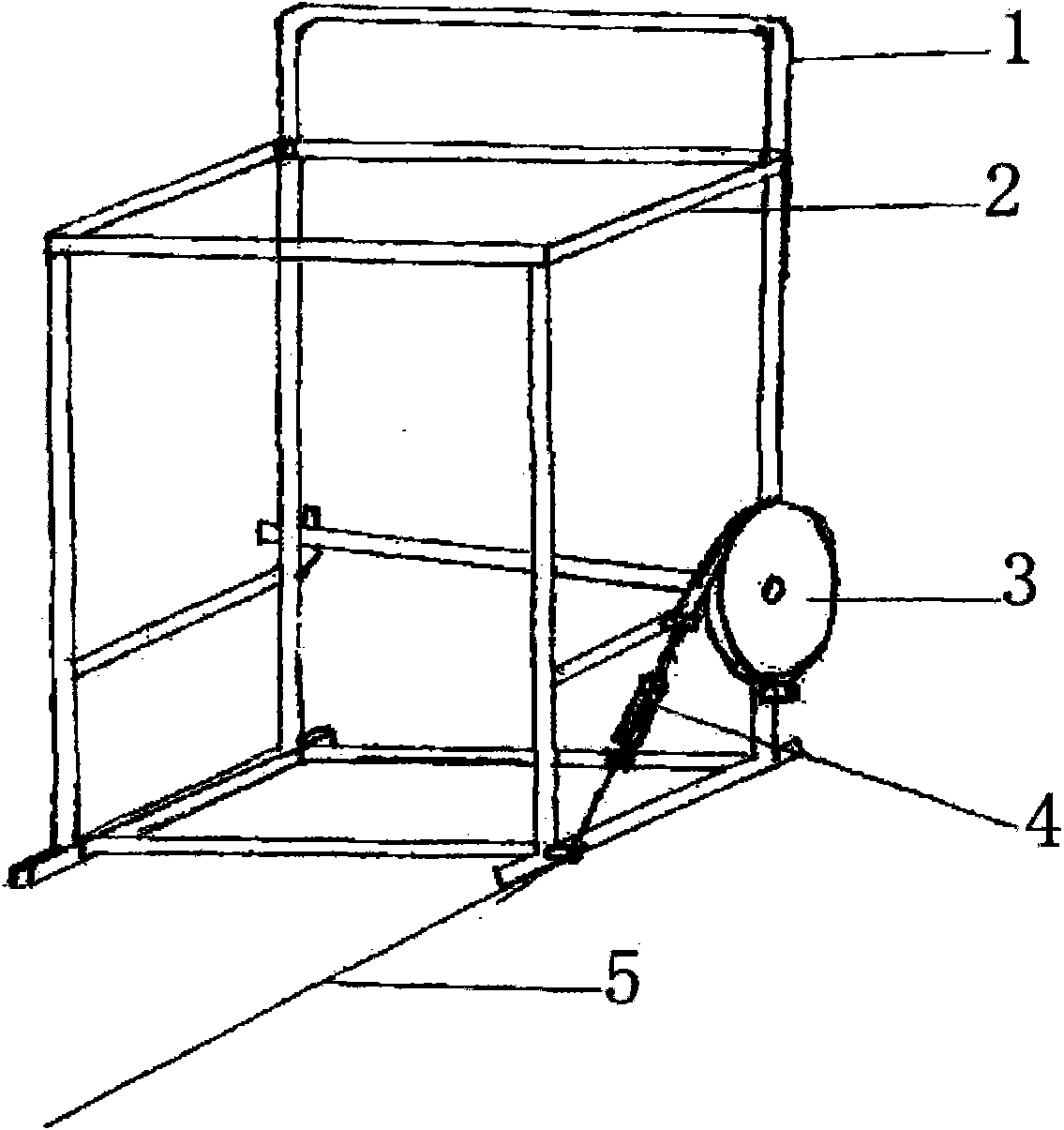

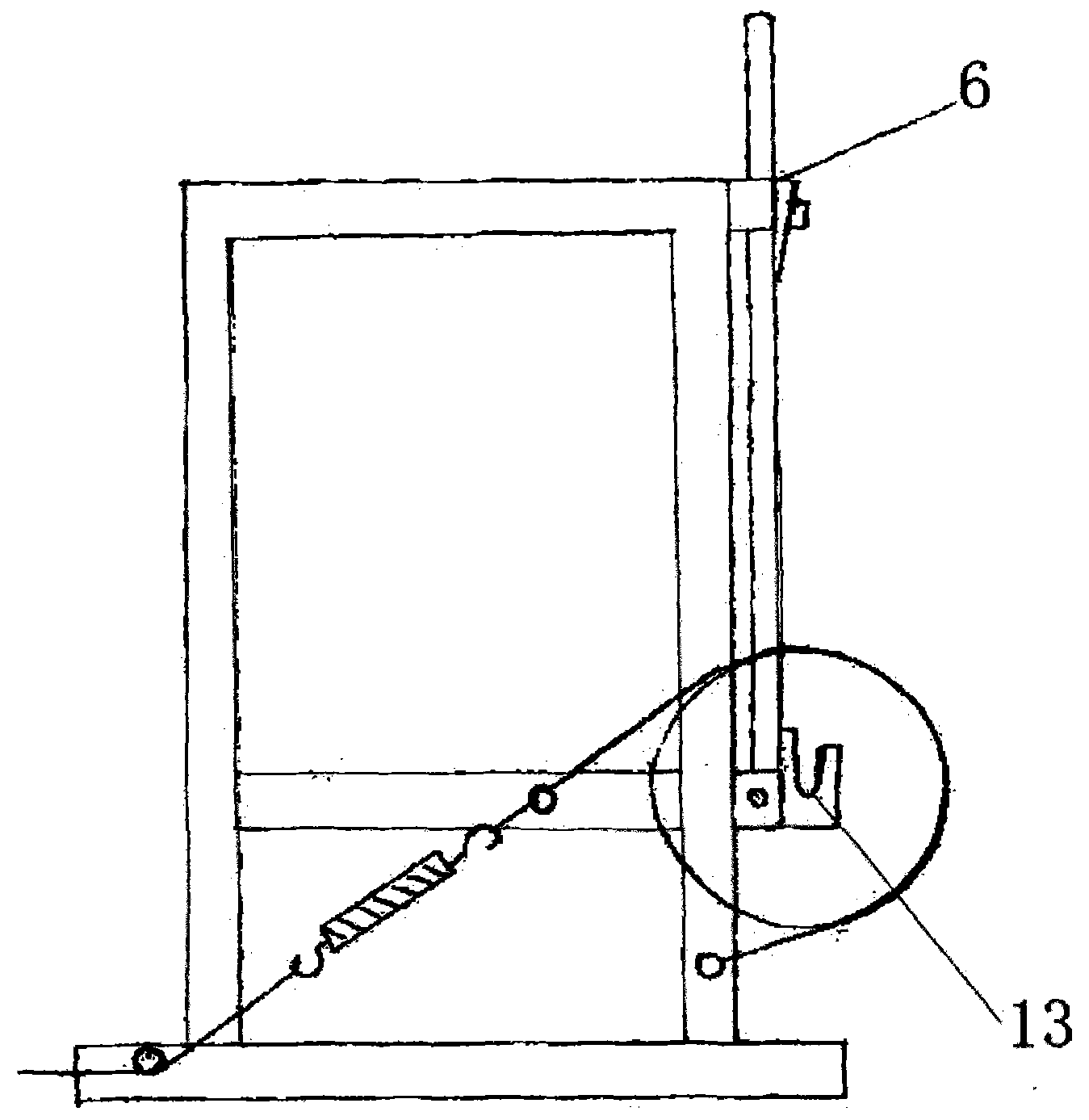

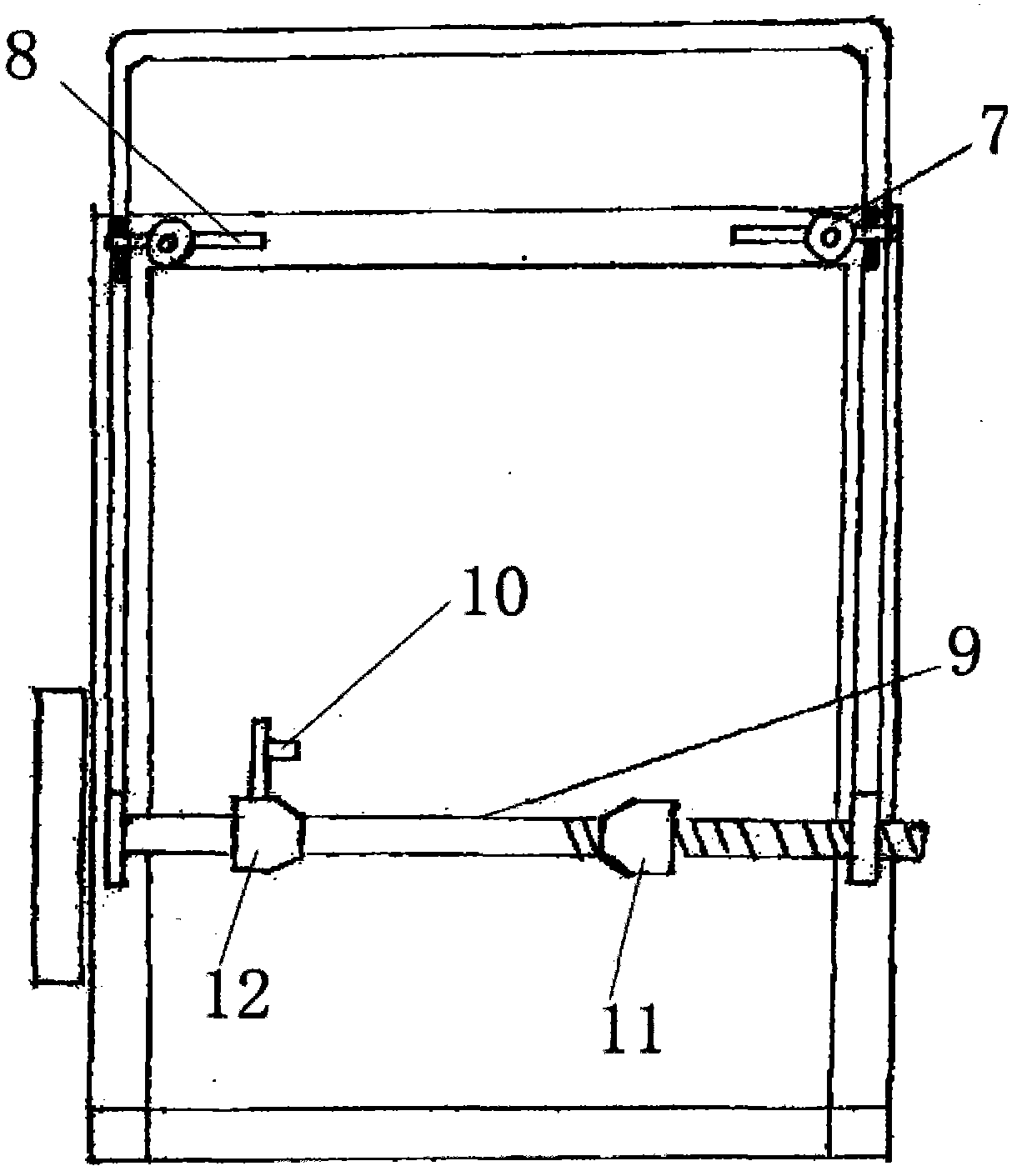

[0023] Such as Figure 1-3 As shown, the pay-off frame of the hard conductor electric wire coiling machine includes a frame 2, an upper roller device arranged on the frame 2, a positioning device and a brake device, and the upper roller device includes a frame arranged on one side of the frame 2, along the The loading and unloading handle 1 that the frame 2 rotates; the positioning device includes a roller positioning mechanism arranged on the loading and unloading handle 1; the braking device includes a brake disc 3 arranged at the lower end of the frame 2, a brake adjuster 4 wound on the brake disc 3, Brake pull rope 5 that is connected with br...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap