A long-life water-based degreasing and anti-rust cleaning agent

A cleaning agent and long-life technology, which is applied in the field of long-life water-based cleaning agent and its preparation, can solve the problems of endangering human health, poor biodegradability, and destroying the ecological environment, so as to reduce the number of tank changes, prolong the cycle of tank changes, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

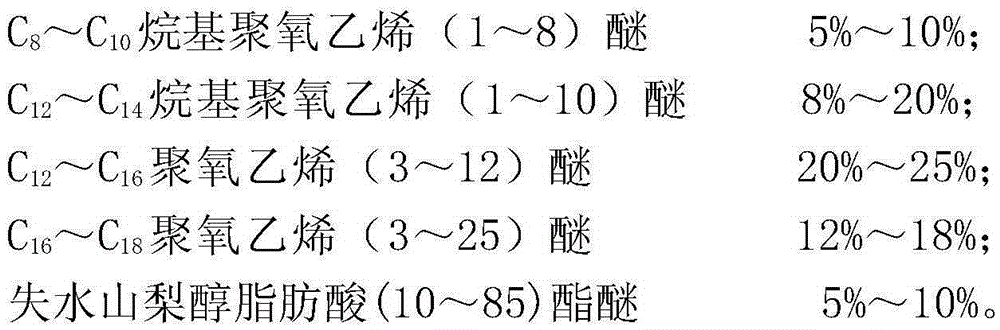

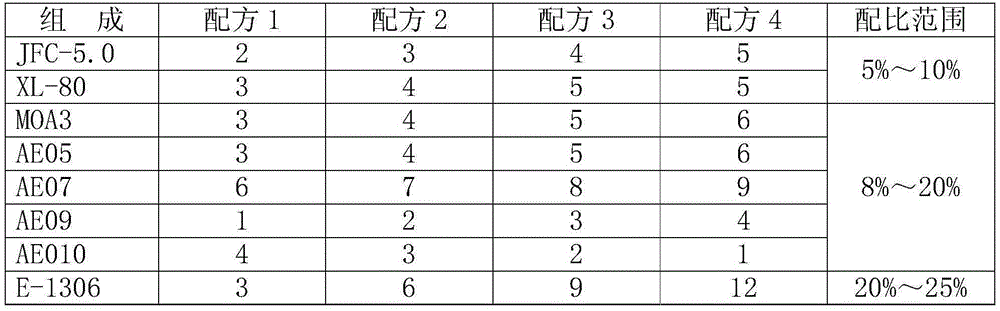

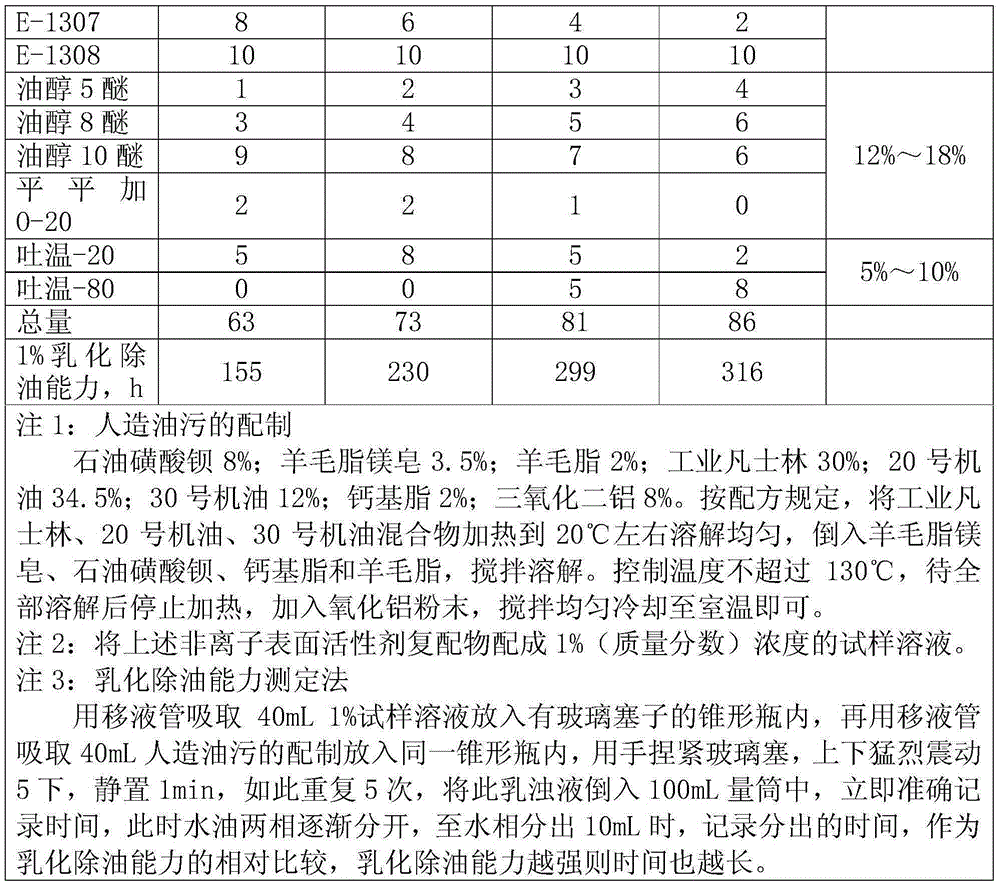

[0047] Example 1 The impact test of nonionic surfactant compatibility on emulsification and degreasing ability

[0048] The nonionic surfactant compound of the present invention was tested for the influence of its compatibility on the emulsification and degreasing ability according to the "emulsification degreasing ability test method", and the results are shown in Table 1.

[0049] Table 1 Nonionic surfactant compatibility test data (mass fraction %) on the influence of emulsification degreasing ability

[0050]

[0051]

[0052] The data in Table 1 shows that formula 2, formula 3 and formula 4 have good emulsification and degreasing ability, indicating that their surfactant compatibility can meet the HLB value requirements of "artificial oil pollution" for emulsification. Therefore, their formulas can also be used as this Invention of a long-life water-based cleaner best choice.

Embodiment 2

[0053] Example 2 Influence Test of Corrosion Inhibitor and Antirust Compound Compatibility on Iron, Aluminum, Copper, Zinc and Their Alloys' Antirust Performance

[0054] The anticorrosion and antirust compound of the present invention is carried out according to the "rust resistance period test" to test the influence of its compatibility on the antirust performance of iron, aluminum, copper, zinc and their alloys. The results are shown in Table 2.

[0055] Table 2 Influence test data (mass fraction %) of corrosion inhibitor compound compatibility on iron, aluminium, copper, zinc antirust performance

[0056]

[0057]

[0058] The data in Table 2 shows that formula 1 and formula 2 have good antirust and corrosion inhibition properties for iron, aluminum, copper, zinc and their alloys, and the antirust period is more than 3 months.

Embodiment 3

[0059] Embodiment 3 cosolvent compound is to the influence test of emulsifying degreasing ability

[0060] The co-solvent compound of the present invention was tested for the influence of its compatibility on the emulsification and degreasing ability according to the "emulsification degreasing ability test method", and the results are shown in Table 3.

[0061] Table 3 co-solvent compound impact test data on emulsification degreasing ability (mass fraction %)

[0062]

[0063]

[0064] The data in Table 3 shows that formula 3 and formula 4 have a good effect of enhancing the emulsification and degreasing ability, indicating that their reasonable compatibility can prolong the life of water-based cleaning agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com