Drawing frame drafting reel device

A technology of drawing frame and pulling device, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and paper making, etc. It can solve the problem of low efficiency of coiling operation of cotton sliver, unfavorable product qualification rate, cotton sliver Easy to get stuck and knotted, etc., to achieve the effect of good product quality, improved production efficiency, and uniform coil density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

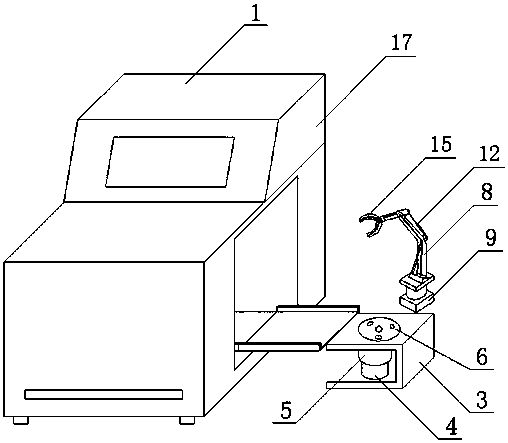

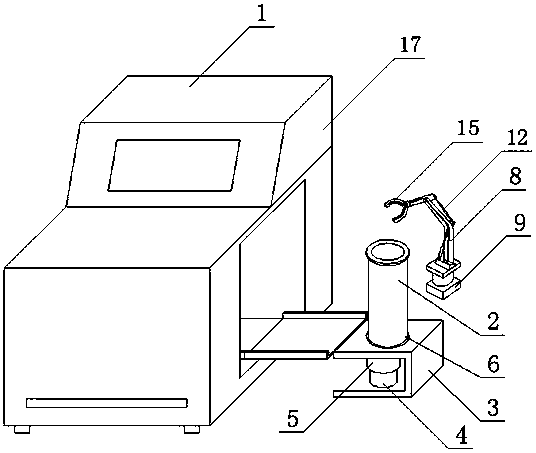

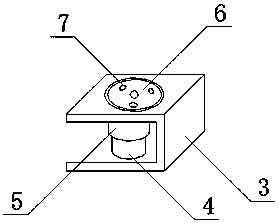

[0019] see Figure 1 to Figure 4 , a drawing frame pulling reel device of the present invention, comprising a draw frame body 1 and a cylinder 2, a rotating base 3 is installed on the outside of the output port of the drawing frame body 1, and the upper surface of the rotating base 3 is set There is a rotating disk 6, and the inside of the rotating base 3 is equipped with a driving motor 4 and a speed reducer 5. The driving motor 4 is connected to the speed reducing machine 5, and the output shaft of the speed reducing machine 5 is fixed on the axis of the rotating disk 6. On the rotating disk 6 A cylinder 2 is placed coaxially, and a sliver pulling device is installed between the output port of the drawing frame body 1 and the cylinder 2, and the pulling movable end of the sliver pulling device is equipped with a grasping claw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com