Environment-friendly dust removal winding device for metallurgical metal wires

A metal wire, winding device technology, applied in the direction of metal extrusion, metal processing equipment, metal extrusion cleaning equipment, etc., can solve the problem of easy mess, can not clean and collect the dust on the surface of the metal wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

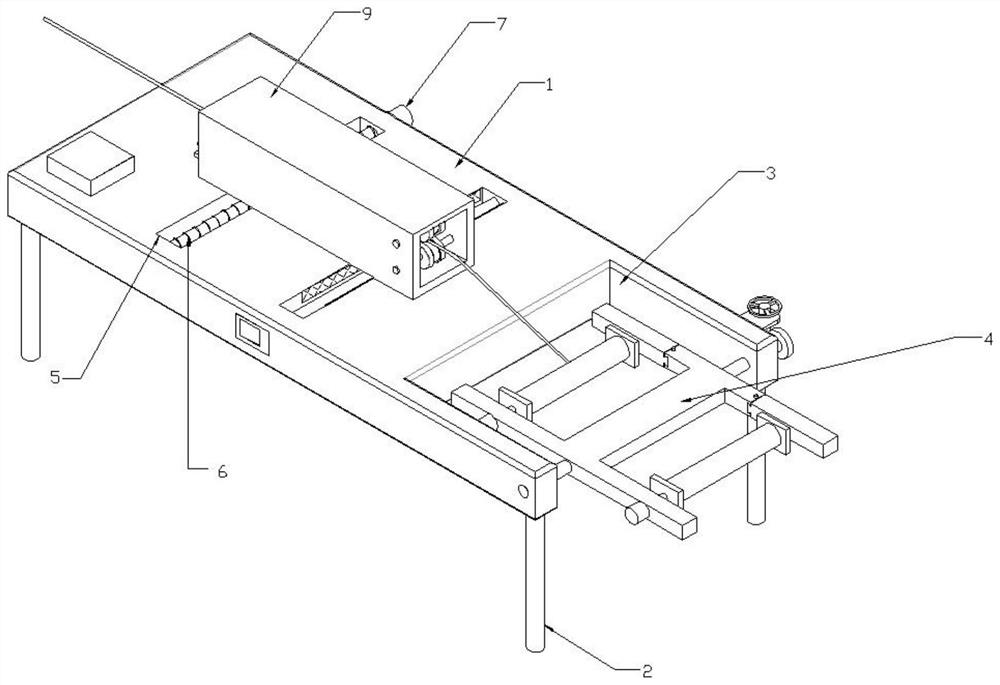

[0028] see Figure 1-2 As shown, the present embodiment is an environment-friendly dedusting and rewinding device for metallurgical metal wire rods, including a workbench 1, the four corners of the bottom of the workbench 1 are connected with uprights 2, and the right end of the workbench 1 is provided with an assembly port 3, and inside the assembly port 3 A coil rack 4 is provided, a longitudinal groove 5 is provided on the top of the workbench 1, and a screw rod 6 is connected to the longitudinal groove 5 for rotation, and a drive motor 7 is connected to the rear end of the screw rod 6, and the drive motor 7 is fixedly connected to the outer wall of the workbench 1 , the outer wall of the screw mandrel 6 is screwed with a nut seat 8, and the upper end of the nut seat 8 protruding from the longitudinal groove 5 is connected with a wire box 9.

[0029] The concrete implementation manner of this embodiment is:

[0030] When the device is in use, it is connected to an external...

Embodiment 2

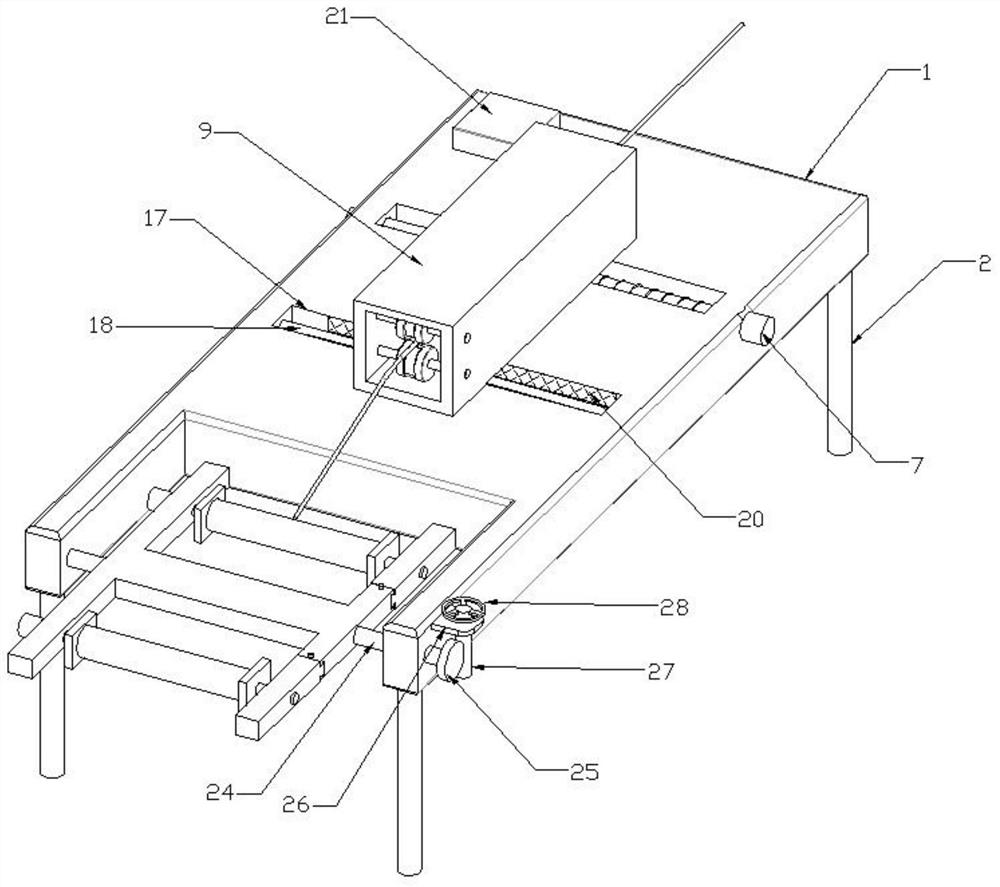

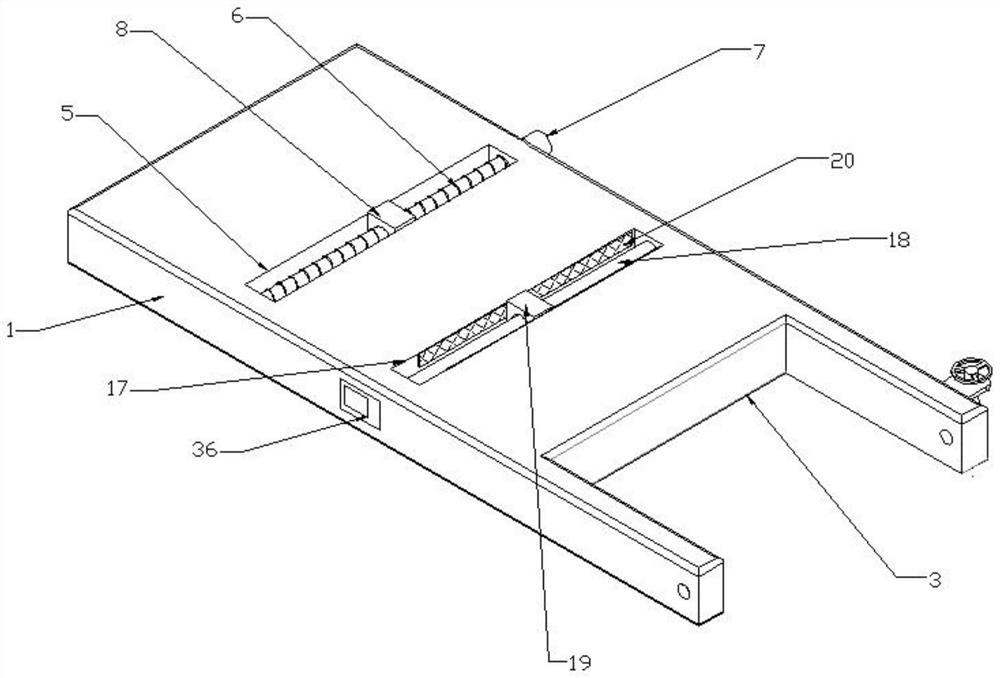

[0032] see Figure 1-4 As shown, on the basis of Embodiment 1, the left and right ends of the wire passing box 9 are opened, the front and rear sides of the inner cavity of the wire passing box 9 are connected with cleaning motors 10, and the power output end of the cleaning motor 10 is connected with a cleaning brush 11 , the positions of the two cleaning motors 10 are staggered, and the bottom of the inner cavity of the wire passing box 9 is provided with a slot 12, and an electrostatic precipitator 13 is movably inserted in the slot 12, and the left end of the electrostatic precipitator 13 is connected with a handle 14, and the wire passing The inner cavity right part of box 9 is symmetrically connected with mounting frame 15 up and down, and the end portion of mounting frame 15 is equipped with guide wheel 16, and the outer wall of two guide wheels 16 all offers annular groove.

[0033] The top of the workbench 1 is provided with a limit groove 17, the limit groove 17 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com