Environment-friendly pollution-free biodegradable adhesive tape and manufacturing process thereof

A biodegradable, non-polluting technology, used in adhesives, bio-packaging, sustainable manufacturing/processing, etc., can solve the problems of low unwinding force, no strong stretching force like BOPP, low noise, etc., and achieve good visual effect, color and luster. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

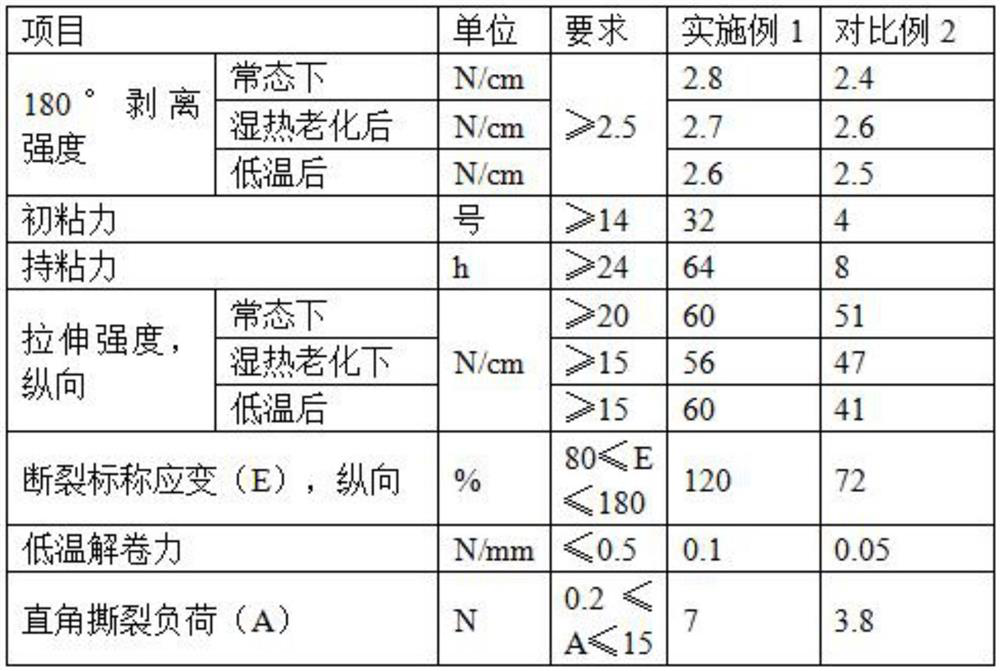

Embodiment 1

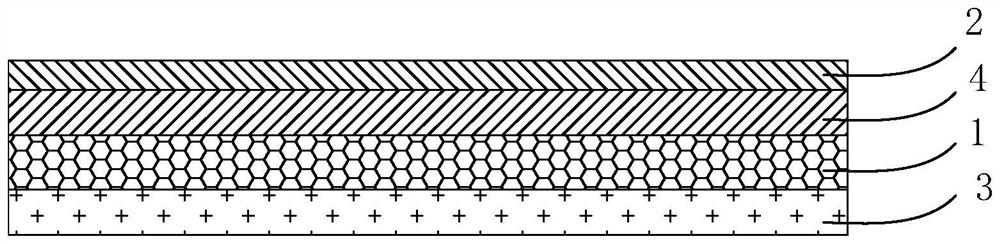

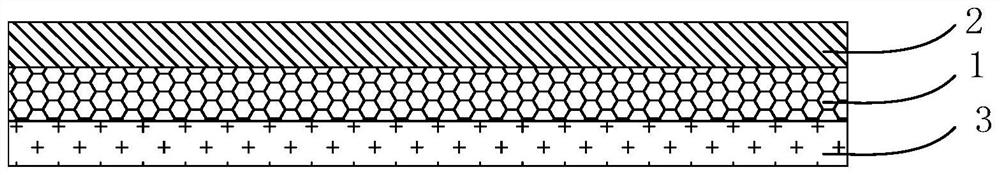

[0031] see figure 1 , an environmentally friendly and pollution-free biodegradable adhesive tape, comprising a substrate layer 1, an adhesive layer 2 formed on one side of the substrate layer 1 and a release layer 3 formed on the other side of the substrate layer 1, the substrate layer 1 is Cellulose film, the adhesive layer 2 is made of adhesive, and an acrylic resin layer 4 is arranged between the base material layer 1 and the adhesive layer 2 .

[0032] The manufacturing process of the above-mentioned environmentally friendly and non-polluting biodegradable adhesive tape is carried out according to the following steps:

[0033] S1: Provide a base material, coat the first surface of the base material with acrylic resin, and dry at 60° C. to form a base material layer 1 having an acrylic resin layer 4;

[0034] S2: Apply 0.1 g of artificial wax per square meter of the substrate on the second side of the substrate, and dry at 60°C to form a release layer 3;

[0035] S3: Prov...

Embodiment 2

[0037] In this embodiment, the structure of the environmentally friendly and pollution-free biodegradable adhesive tape is the same as that of Embodiment 1, the difference is: its production process is carried out according to the following steps:

[0038] S1: Provide a base material, coat the first surface of the base material with acrylic resin, and dry at 55°C to form a base material layer 1 with an acrylic resin layer 4;

[0039] S2: Apply 0.18 grams of artificial wax per square meter of the substrate on the second side of the substrate, and dry at 55°C to form a release layer 3;

[0040] S3: Provide pressure-sensitive adhesive, water and hydrogen peroxide, mix the pressure-sensitive adhesive and water in a weight ratio of 40:60, then add hydrogen peroxide, and the amount of hydrogen peroxide added is 0.4% of the total mass of the pressure-sensitive adhesive and water to make an adhesive; The adhesive is coated on the upper surface of the acrylic resin layer 4 and dried at...

Embodiment 3

[0042] In this embodiment, the structure of the environmentally friendly and pollution-free biodegradable adhesive tape is the same as that of Embodiment 1, the difference is: its production process is carried out according to the following steps:

[0043] S1: Provide a base material, coat the first surface of the base material with acrylic resin, and dry at 50° C. to form a base material layer 1 having an acrylic resin layer 4;

[0044] S2: Apply 0.3 grams of artificial wax per square meter of the substrate on the second side of the substrate, and dry at 50°C to form a release layer 3;

[0045] S3: Provide pressure-sensitive adhesive, water and hydrogen peroxide, mix the pressure-sensitive adhesive and water in a weight ratio of 50:50, then add hydrogen peroxide, and the amount of hydrogen peroxide added is 0.6% of the total mass of the pressure-sensitive adhesive and water to make an adhesive; The adhesive is coated on the upper surface of the acrylic resin layer 4 and dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com