A wear-resistant and heat-insulating window film and its preparation method and application method

A technology of heat-insulating window film and wear-resistant layer is applied in the field of preparing heat-insulating window film, which can solve problems such as temperature rise in the car, and achieve the effect of prolonging the service life and improving the heat-insulating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

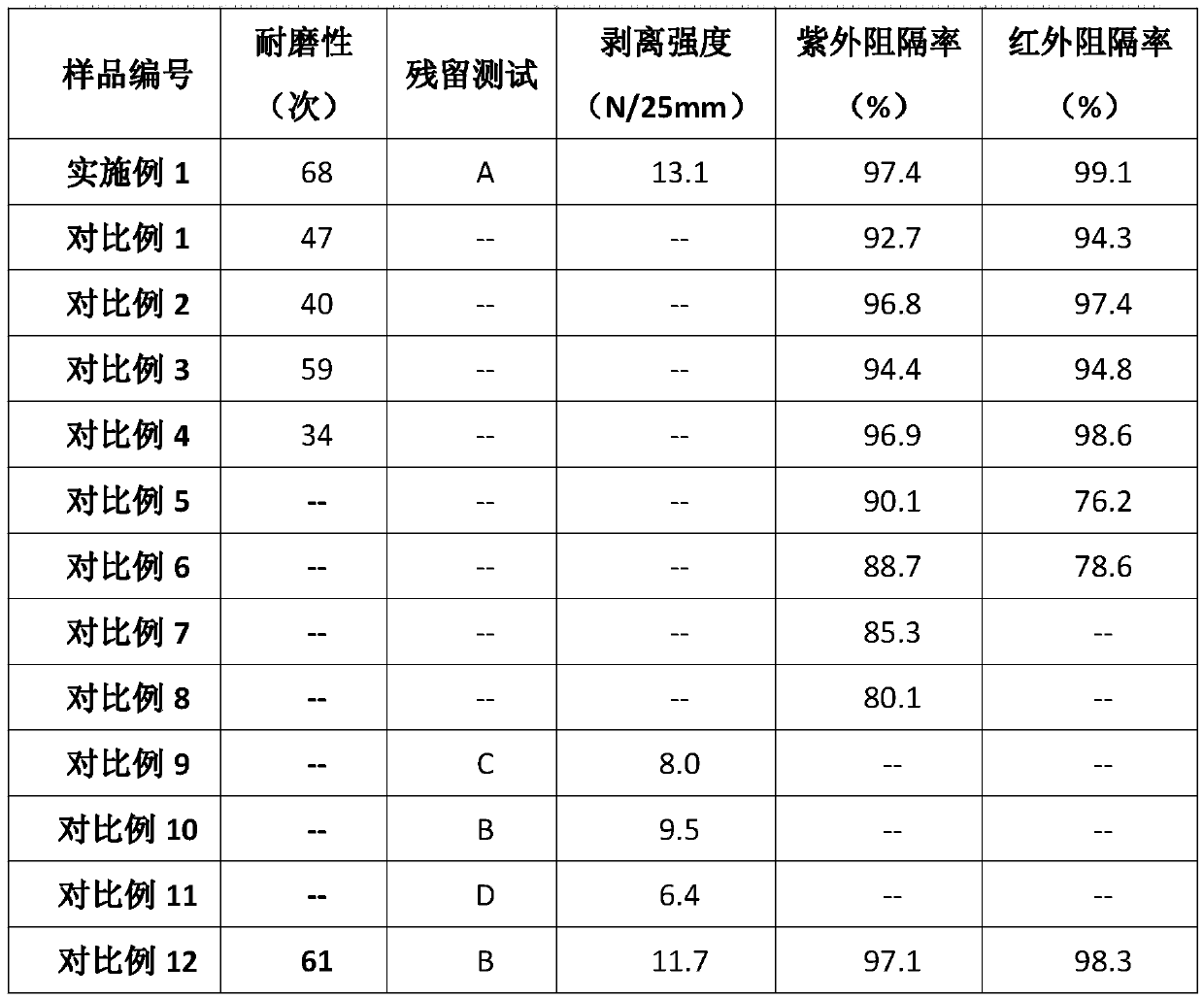

Examples

preparation example

[0047] 1. Wear-resistant materials

[0048] Wear-resistant material 1: 36 parts by weight of corundum powder and 2 parts by weight of graphite powder were pre-mixed to obtain a mixed filler, and then 100 parts by weight of epoxy-modified silicone resin, 2 parts by weight of siloxane coupling agent KH560, and 0.5 parts by weight of defoaming agent Parts by weight, 0.08 parts by weight of catalyst, 6 parts by weight of polyamide curing agent, and 38 parts by weight of composite filler were uniformly mixed in a kneader to obtain wear-resistant material 1.

[0049] Wear-resistant material 2: 100 parts by weight of epoxy modified silicone resin, 2 parts by weight of siloxane coupling agent KH5602, 0.5 parts by weight of defoamer, 0.08 parts by weight of catalyst, 6 parts by weight of polyamide curing agent, 38 parts by weight The corundum powder was uniformly mixed in a kneader to obtain wear-resistant material 2.

[0050] Wear-resistant material 3: 100 parts by weight of epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com