Cutting machine

A cutting machine and cutting technology, applied in the cutting of textile materials, washing devices, textiles and papermaking, etc., can solve problems such as off-line, tissue damage, and tissue expansion, and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

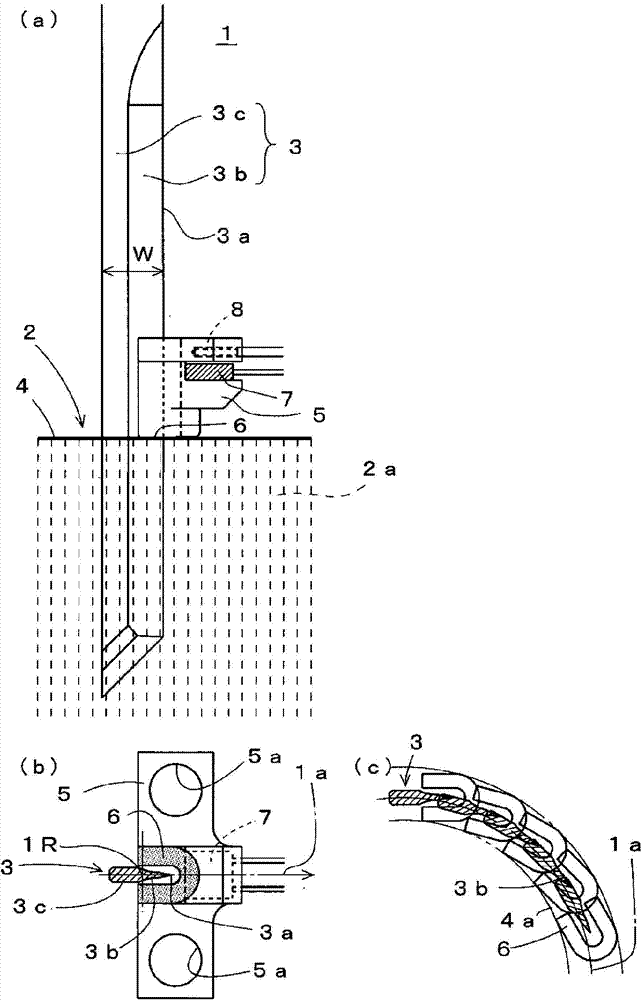

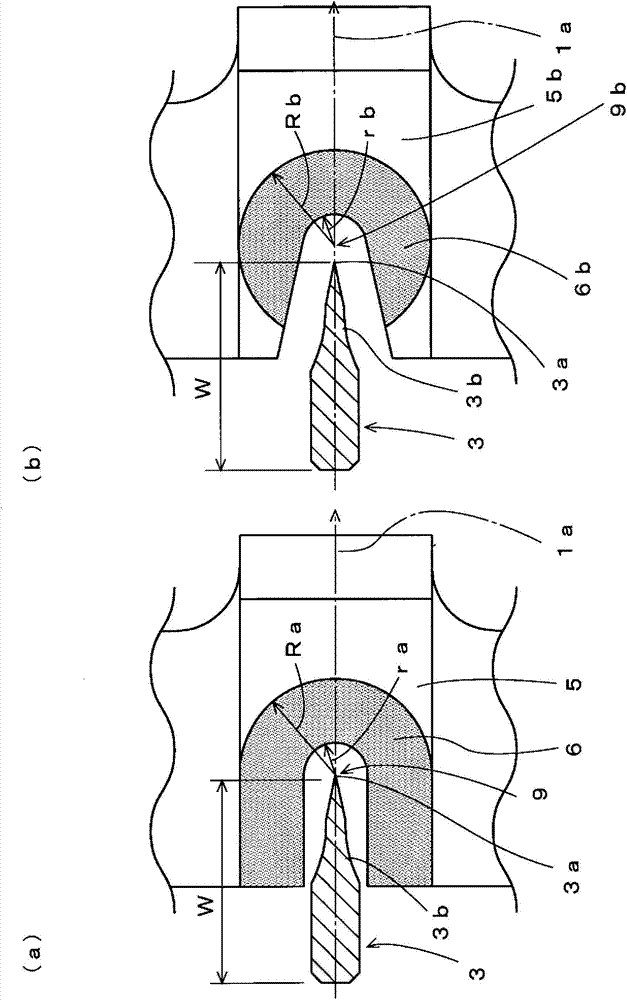

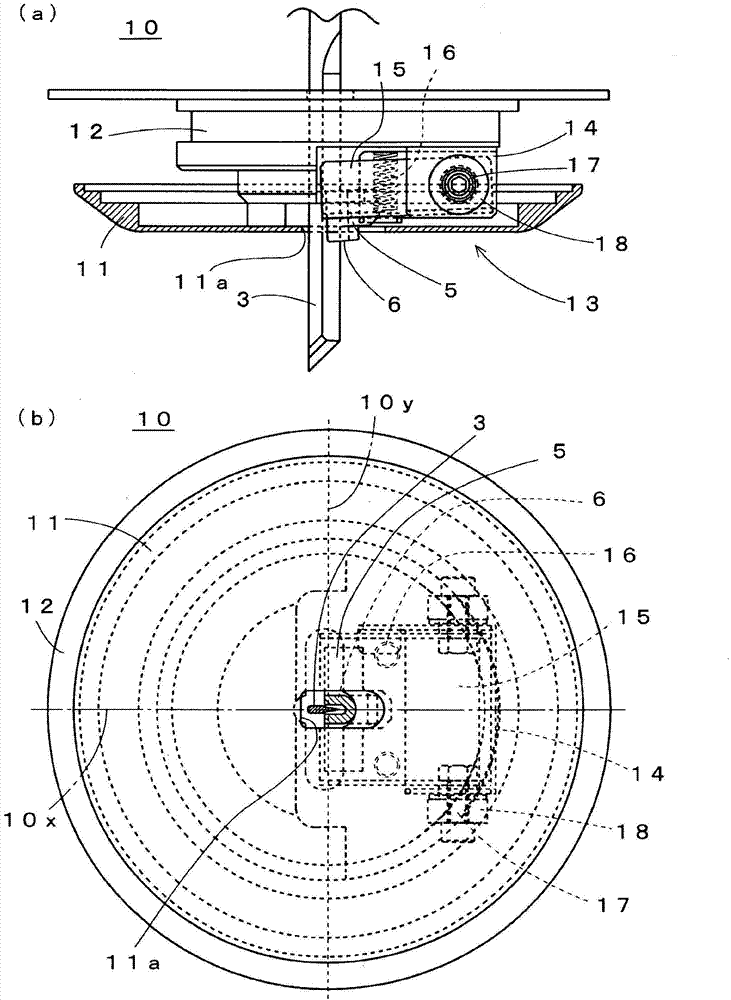

[0035] figure 1 (a) The structure of the main part of the cutting machine 1 which is Example 1 of this invention is shown in simplified form. The cutting machine 1 includes a cutting table 2 and a cutting blade 3 provided on a cutting head movable along the surface of the cutting table 2 . The cutting blade 3 is, for example, provided with a linear blade 3a in a direction perpendicular to the surface of the cutting table 2, reciprocates in this direction, and at the same time, cuts and is placed on the cutting table 2 by the blade portion 3b having the blade 3a as the front end. Sheet material 4. In the cutting table 2 , for example, a vacuum suction device is installed below, and the sheet material 4 is sucked and held by the surface of the cutting table 2 . During cutting, the cutting blade 3 penetrates into the surface of the cutting table 2 with a blade width W including the blade portion 3b and the blade portion 3c. The surface of the cutting table 2 is formed of brist...

Embodiment 2

[0053] exist Figure 6 In the cutting machine 21 shown in (a), the sheet material 4 is cut by the cutting blade 23 of the blade width W2 which is used fixedly without moving up and down. Although the blade 23a is inclined relative to the surface of the cutting table 2, it can be used with figure 1 The same heating member 5 heats the periphery of the blade 23a including the front in the cutting direction to perform off-line locking. In the cutting blade 23, if the sharpness of the blade 23a becomes poor, the cutting blade 23 is raised and lowered to change the position of the blade 23a within the blade width W2. When using to the vicinity of the lower end of the cutting blade 23 , the heating surface 6 may extend to the left in the drawing to surround the entire cutting blade 3 from the outside.

Embodiment 3

[0055] exist Figure 6 Also in the cutting machine 31 shown in (b), the sheet material 4 is cut by the cutting blade 33 which is used fixedly without moving up and down. In the cutting blade 33, blades 33a are provided on both sides of the lower end within the blade width W3. The heating member 5 is provided in front of the blade 33a used for cutting. When changing the direction of the blade 33a used for cutting, it is only necessary to replace the cutting blade 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com