Wallpaper coating adsorption mechanism

An adsorption mechanism and coating technology, which is applied in the direction of papermaking, textiles and papermaking, pulp raw material addition process, etc., can solve the problems such as the adverse effect of wallpaper coating base material coating, the quality of coating base material is difficult to guarantee, etc., to achieve coating The process is stable and reliable, and the effect of changing the waste problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

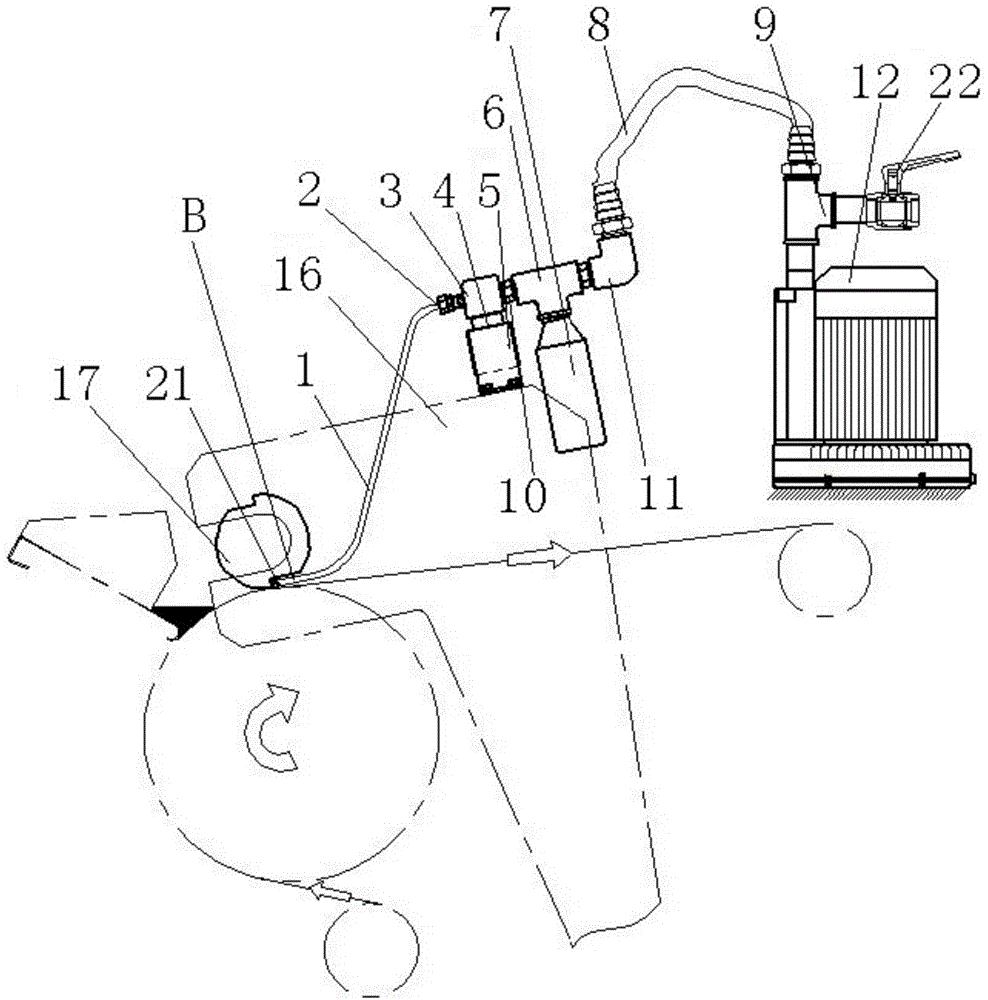

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

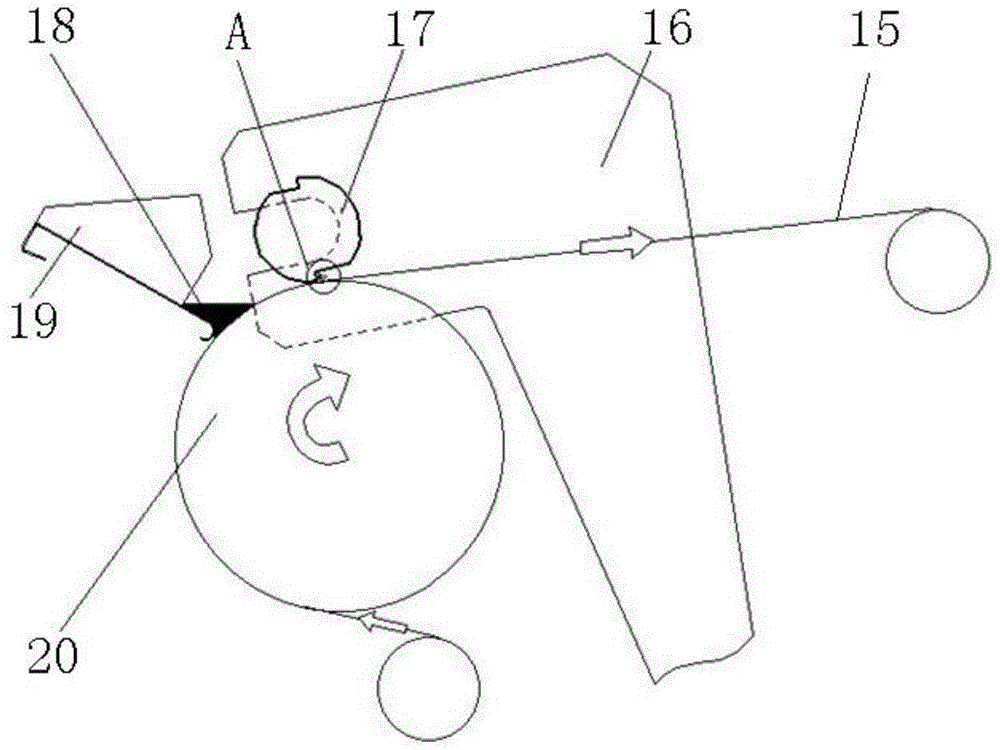

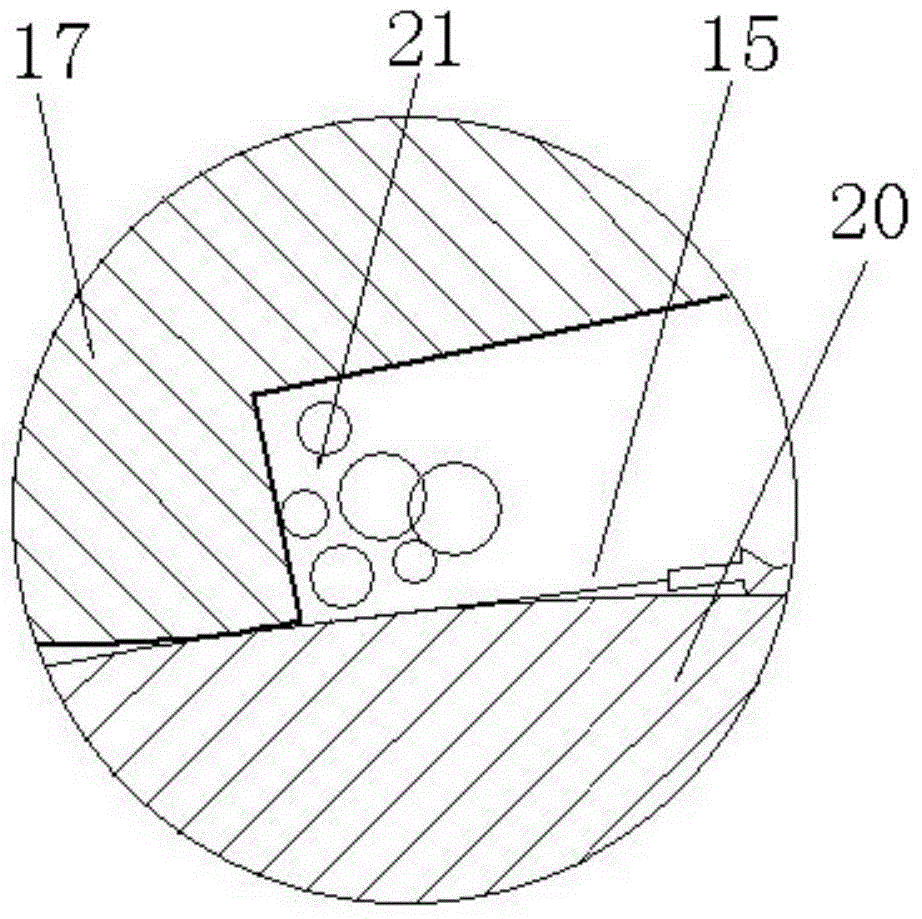

[0018] figure 1 , figure 2 It is a schematic diagram of the structure of the existing coating head, and the components 15-20 are the existing structures.

[0019] Such as figure 1 As shown, a coating roller 20 is included, and the coating substrate 15 moves around the coating roller 20, and a comma scraper 17 and a material blocking plate 19 are correspondingly arranged above the coating roller 20, and the comma scraper 17 is installed on the scraper swing arm 16, Slurry 18 is contained in the triangular area that cooperates between the coating roller 20 and the baffle plate 19 .

[0020] The action process under normal conditions is that when the coating roller 20 rotates, the slurry 18 passes through the pre-adjusted uniform gap between the comma scraper 17 and the coating roller 20 under the guidance of the coating substrate 15, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com