Device and method for recovering silicon dioxide after burning waste gas and waste liquid in polycrystalline silicon industry

A silicon dioxide and polysilicon technology, applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problems of large environmental pollution, occupying a larger site, waste of resources, etc., and achieve the effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

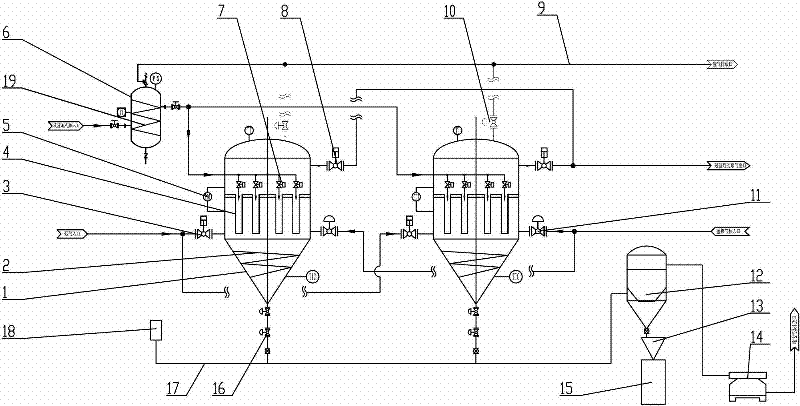

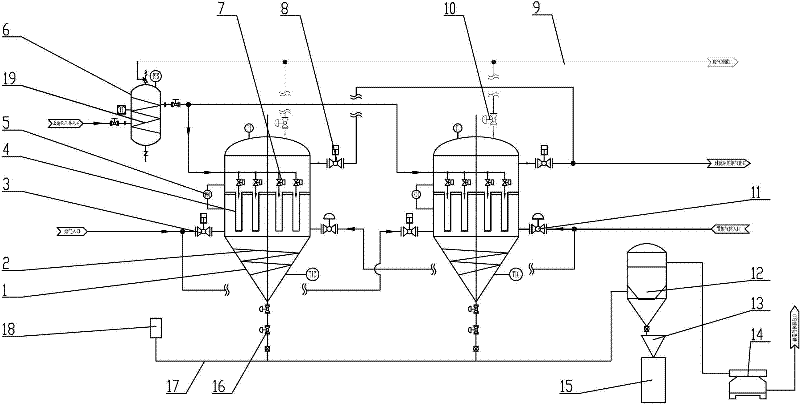

[0027] As shown in the figure, the device for recovering silicon dioxide after incineration of waste gas and liquid in the polysilicon industry is as follows:

[0028] Connect the flue gas delivery pipe to the flue gas inlets of two metal element filters 1 connected in parallel. The powder outlet end of the metal element filters 1 is equipped with a discharge valve 16, which is connected to the negative through the pipeline. In the middle section of the pressure delivery pipeline 17, the inlet end of the negative pressure delivery pipeline 17 is provided with an air inlet filter 18, and the outlet end of the negative pressure delivery pipeline 17 is connected with the powder inlet end of the powder collector 12, and the powder collector 12 The powder outlet port of the powder is connected with the inlet port of the degasser 13, and the outlet port of the degass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com