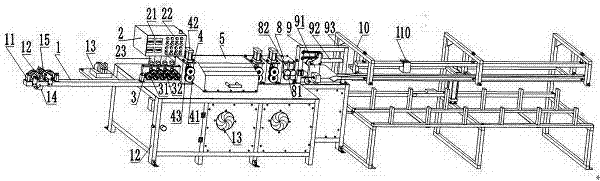

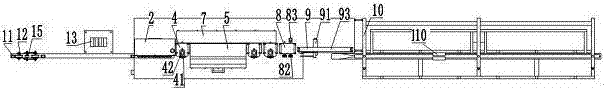

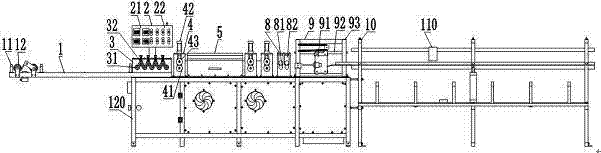

A cloud automatic CNC bag cage straightening machine

A fully automatic, straightening machine technology, applied in the field of straightening machines, can solve the problems of broken wires, unrealizable, time-consuming and other problems in fixed wire cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Automatic feeding tray

[0037] The automatic discharge tray 130 is located at the beginning of the whole equipment, including a bracket 133, a discharge disc 132, and a guide wire column. The top of the bracket 133 is provided with a discharge disc 132, and the outside of the discharge disc 132 is fixed on the bracket. The bracket 133 is also equipped with a motor, a fault alarm device, a frequency converter, and a moving wheel. The motor is connected to the discharge disc 132 through a shaft and a bearing, and a central column 131 is provided in the middle of the discharge disc 132; The fault alarm device is equipped with a travel switch, the travel switch is connected with the frequency converter, and the frequency converter is connected with the motor and the switchboard respectively.

[0038] The upper disc is used to store raw materials, and the lower part is driven by a variable-frequency decelerating motor. When the equipment is running, the unwinding tray rotates sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com