Thermostatic valve with preset flow distribution ratio

A technology of distribution ratio and preset flow rate, which is applied in the field of thermostatic valves, can solve the problems of inconsistent manual adjustment, difficult balance of hot water flow, and poor heating comfort, so as to reduce waste of hot water resources, flexible and convenient production, Solve the effect of a single fixed ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

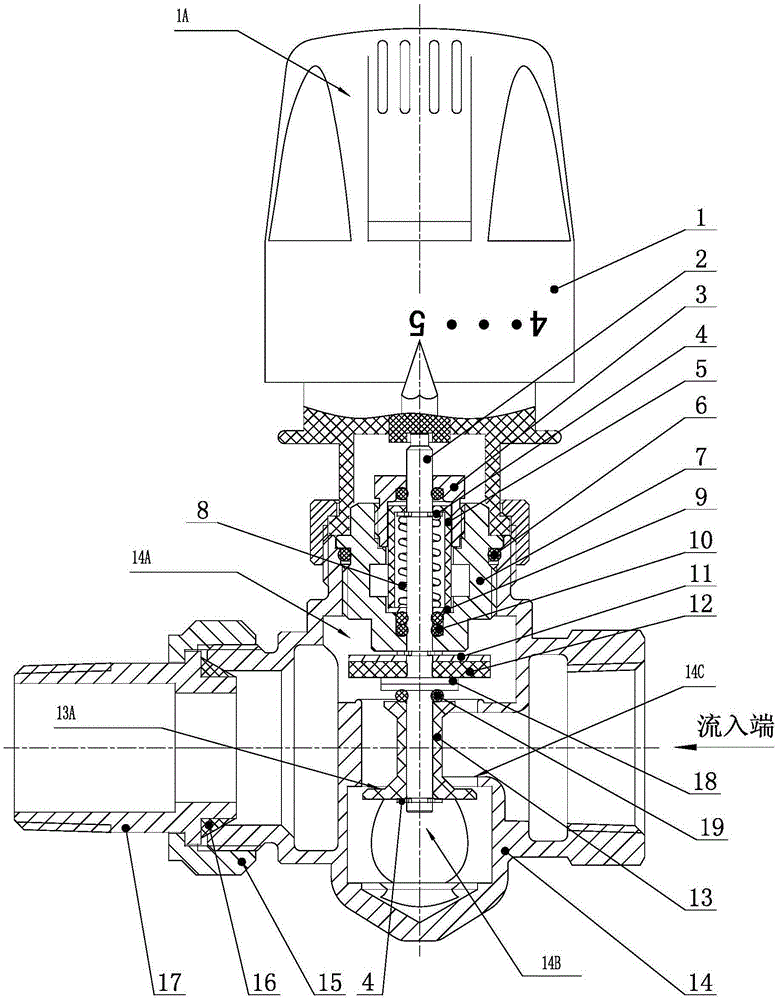

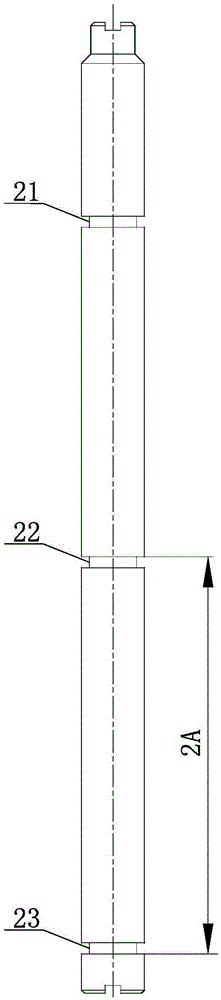

[0016] Such as figure 1 , figure 2 As shown, the thermostatic valve with a preset flow distribution ratio of the present invention includes a valve body 14 with a mandrel 2, a valve cover 7 and a thermostatic valve controller 1, the mandrel 2 is installed in the valve body 14, and the thermostatic valve controller 1 Installed outside the valve body 14, the lower end of the mandrel 2 extends into the bypass chamber 14B of the valve body 14, and the upper end of the mandrel 2 extends out of the valve body 14 after passing through the valve cover 7 and is connected with the thermostatic valve controller 1 . The improvement of the present invention is that: on the outer wall of the mandrel 2, limit card slot one 21, limit card slot two 22, limit card slot three 23, limit card slot one 21, position limit The second draw-in slot 22 and the third limit draw-in slot 23 are fitted with an opening retaining ring 4, the limit draw-in slot one 21 is located in the valve cover 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com