Flange leaking stoppage fixture

A clamp and leak clamp technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of uneven force, short duration, large injection consumption, etc., to achieve the effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

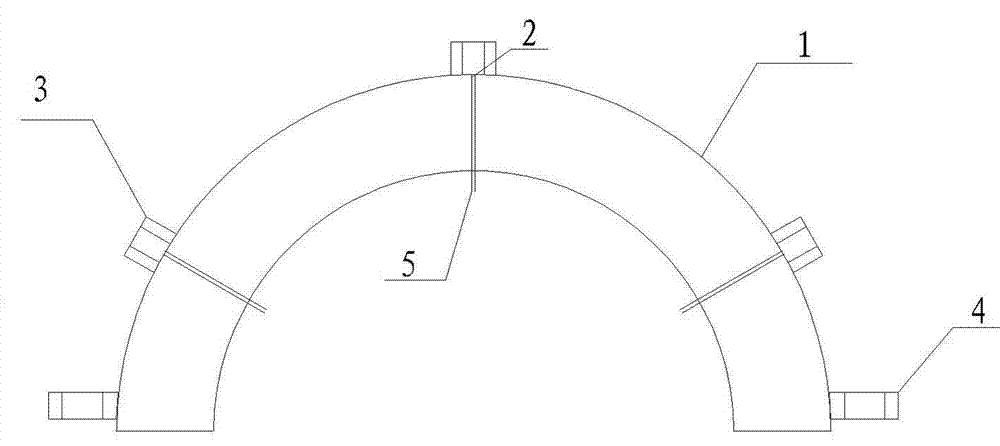

[0014] Such as figure 1 As shown, the flange plugging fixture includes a fixture body 1 that is a semicircular strip, and three injection tubes 2 pass through the fixture body 1. One end of the injection tube 2 is a glue injection head 5 and the other end can be screwed into an injection nut 3. The clamp body 1 is provided with a connecting ring 4; the clamp body 1 is made of rubber.

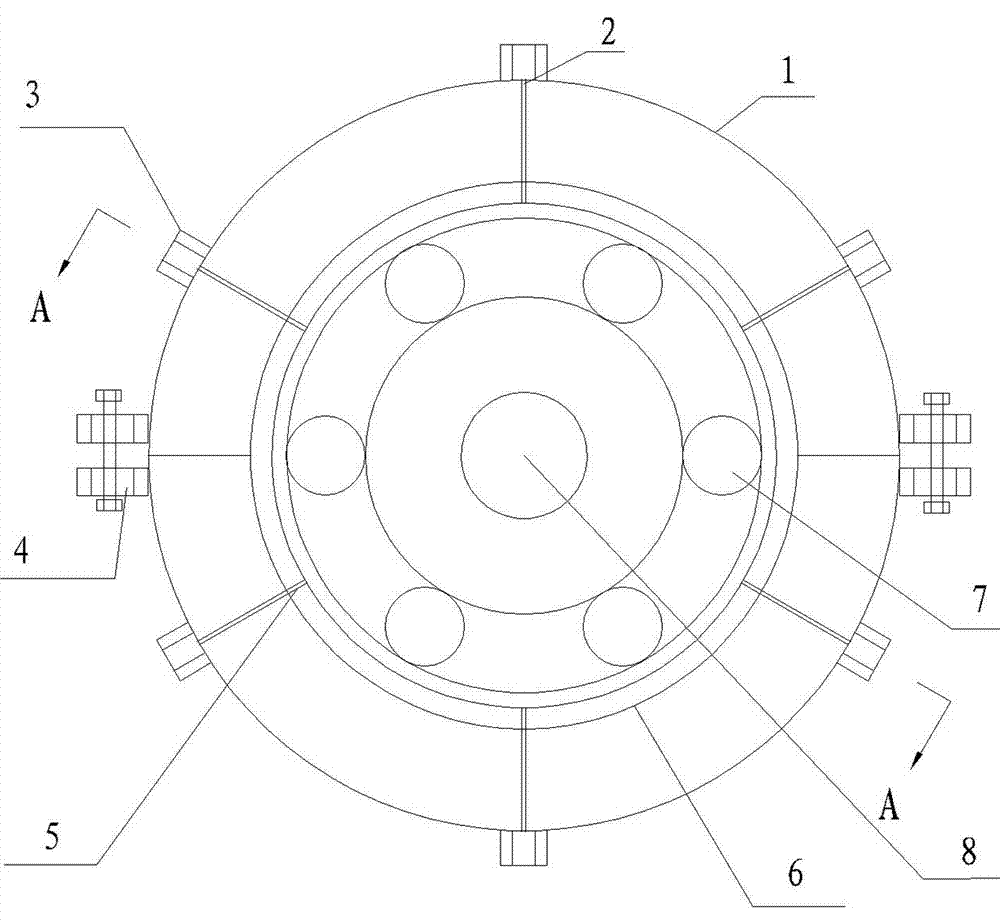

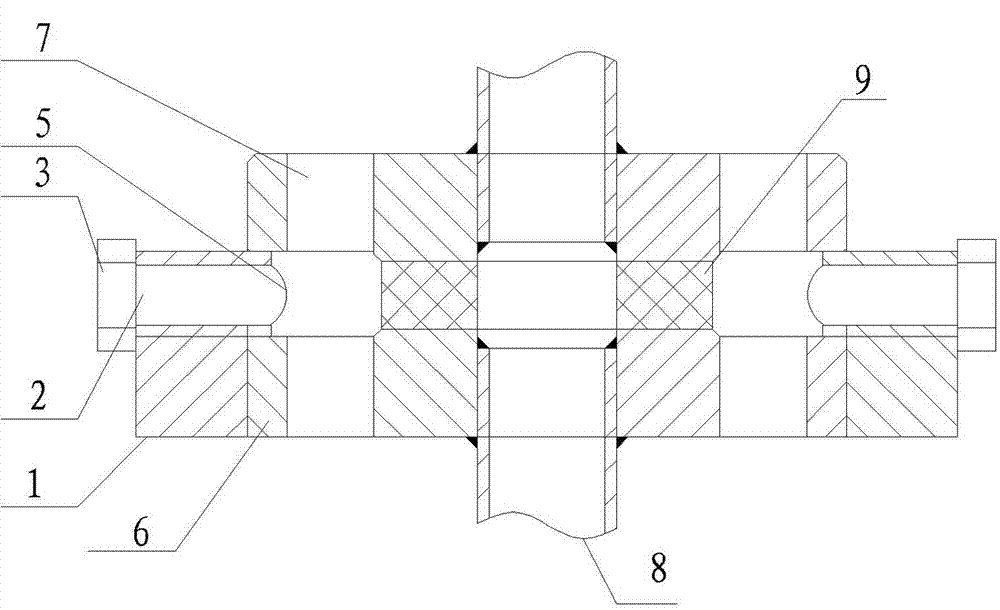

[0015] Such as figure 2 , image 3 As shown, the fixture body 1 of the flange plugging fixture is close to the flange 6, the injection head 5 extends into the gap between the clips of the flange 6, the injection nut 4 is screwed into the injection tube 2, and passes through the tight fixture The connecting ring 4 on the body 1 penetrates the bolts and fastens on the flange 6 with nuts, the bolt holes 7 of the flange 6, the main pipe 8 is the connecting pipe of the flange 6, and gaskets 9 are arranged between the clips of the flange 6.

[0016] Working principle: When in use, the fixture body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com