High damping vibration test clamp

A vibration test, high damping technology, applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve problems such as small damping of fixtures, and achieve the effect of increasing damping and improving transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

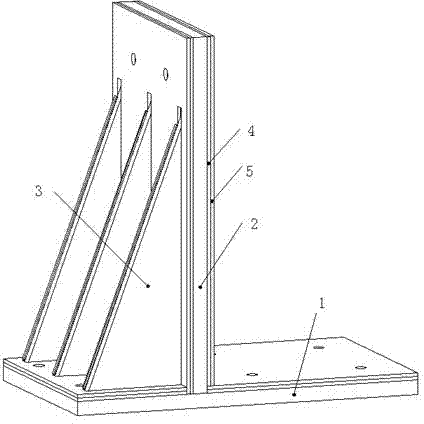

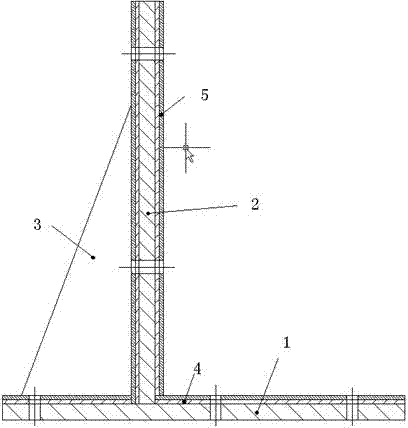

[0015] A high-damping vibration test fixture includes: a connecting bottom plate 1, connecting vertical plates 2 and reinforcing ribs 3, and also includes: a high-damping rubber layer 4 and a constraint layer 5.

[0016] The connection bottom plate 1 and the connection riser 2 are steel rectangular plates, the connection bottom plate 1 is placed horizontally, the connection riser 2 is placed vertically, the connection riser 2 is perpendicular to the connection bottom plate 1 and fixed by welding; the reinforcing rib 3 is a steel triangle, Reinforcement rib 3 is N pieces, among which 2≤N≤5, reinforcement rib 3 is perpendicular to connection bottom plate 1 and connection riser 2 and welded with connection bottom plate 1 and connection riser 2 respectively; high damping rubber layer 4 is pasted on connection bottom plate 1 , connecting the outer surfaces of the risers 2 and the reinforcing ribs 3 , the constraining layer 5 is pasted on the outer surfaces of the high damping rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com