Method and device for detecting three-dimensional distribution of absorption characteristics in transparent optical material body

An optical material, three-dimensional distribution technology, applied in the direction of material analysis, measurement device, and material analysis by optical means, can solve the problems of material damage and damage, difficult to absorb defects, etc., and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

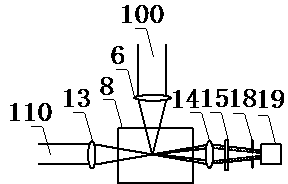

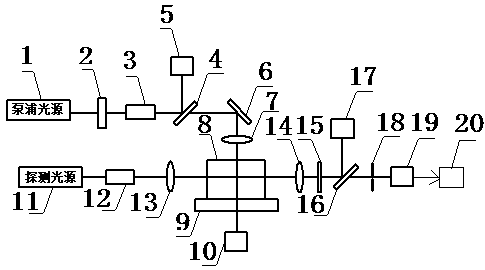

[0028] Such as figure 1 As shown, the pump light beam 100 is focused on the measured transparent optical material 8 through the pump light converging device 6, and the focal point is in the measured transparent optical material body. Due to the absorption of the pumping light energy by the transparent optical material 8 itself, the temperature in the area where the pump beam 100 passes will cause its temperature to rise, thereby causing changes in the physical properties of the transparent optical material 8 to be tested, such as thermal expansion, refraction, etc. rate changes, etc. At the focus position, because the laser energy is most concentrated, the physical property change of the transparent optical material 8 to be tested is also the most significant. At this time, a weaker probing beam 110 is used, the propagation direction is perpendicular to the propagating direction of the pumping beam 100, and is focused into the transparent optical material 8 to be tested via t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com