A high-speed railway power supply arm joint trip protection method based on current characteristics

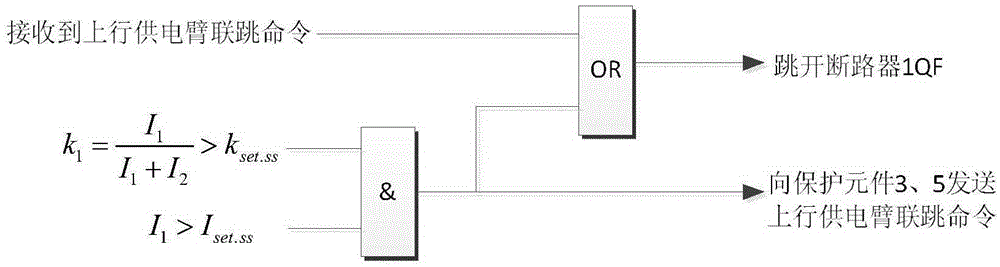

A technology for current protection and high-speed railways, applied to emergency protection circuit devices, electrical components, etc., can solve problems such as unsatisfactory protection selectivity, unrecognizable end high-resistance faults, high-speed EMU load current, etc., to improve protection Sensitivity, prevention of misjudgment, small power failure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation. The drawings and specific embodiments do not limit the scope of protection claimed by the present invention.

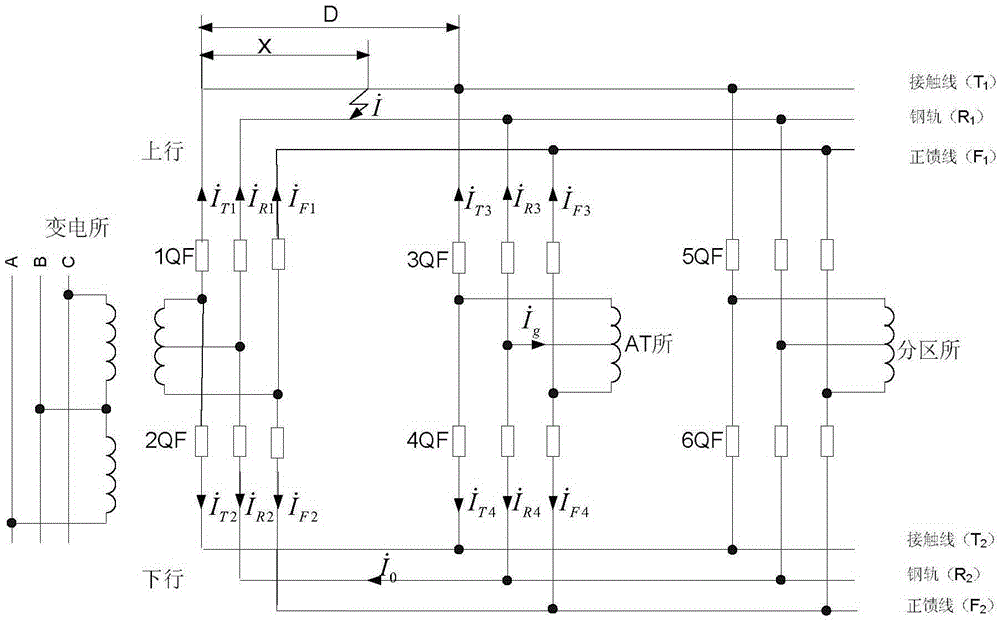

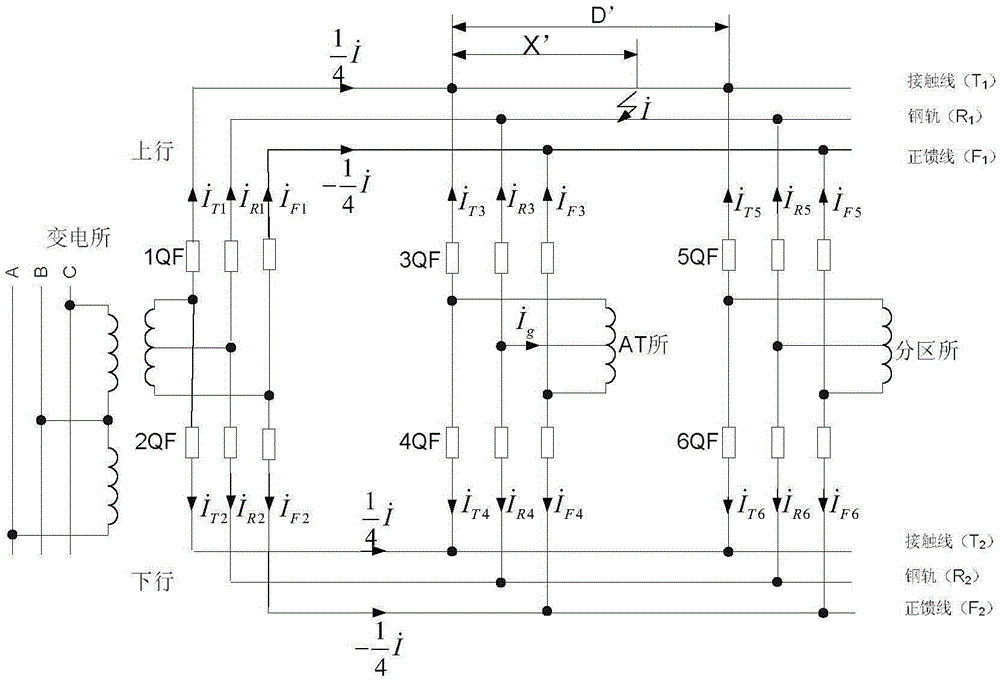

[0025] When a short-circuit fault occurs between the substation and the AT station, in the fault section, the upstream and downstream T 1 with T 2 , F 1 with F 2 , R 1 with R 2 The loops are formed respectively, and three loop voltage equations can be obtained:

[0026] I · T 1 Z T X - I · T 3 Z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com