Winding apparatus

A technology of winding device and imaginary wire, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as winding slack, and achieve the effect of reducing position changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

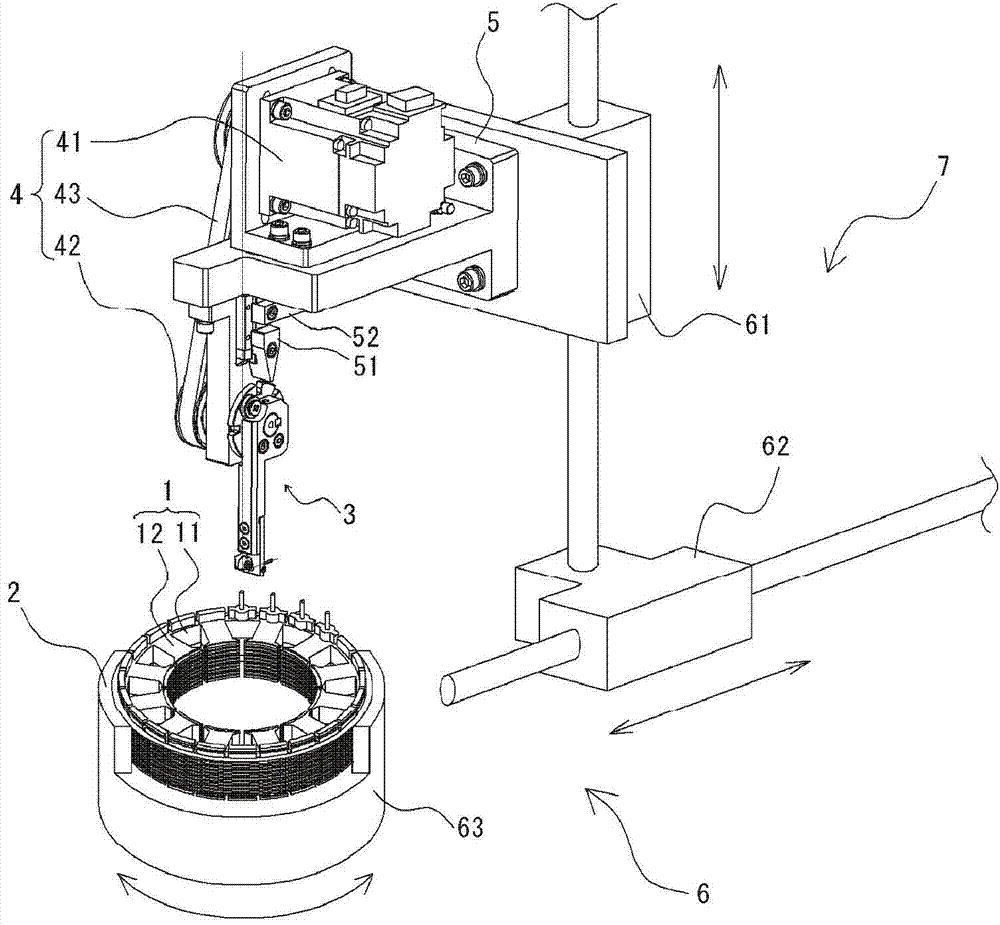

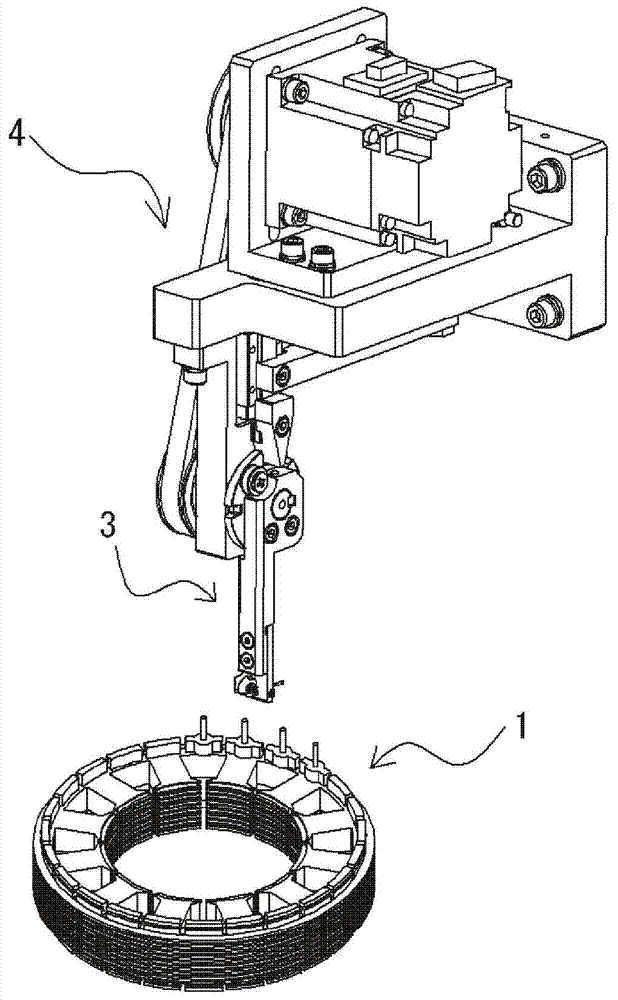

[0020] figure 1 It is a perspective view of the winding device concerning this invention. Such as figure 1 As shown, the winding device includes a core holding portion 2 , an arm portion 3 , an arm rotation mechanism 4 , and a support portion 5 . The core holder 2 holds the annular core 1 . The arm portion 3 has a columnar shape having a hole or a groove-shaped guide portion through which the wire rod passes at the distal end. The arm rotation mechanism 4 rotates the arm 3 near the proximal end to change the posture of the arm 3 . The support portion 5 supports the arm rotation mechanism 4 . The winding device further includes a relative movement mechanism 6 for changing the relative position of the support portion 5 and the iron core 1 . In this example, the relative movement mechanism 6 also functions as a support portion moving mechanism 7 that moves the support portion 5 . The relative movement mechanism 6 includes a vertical movement mechanism 61 that moves the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com